On average, screens move through 14-17 fatigue cycles per second, operating 24/7. In just a couple of days, it’s possible for a machine to complete millions of fatigue cycles. (Photo: Weir Group)

From customized models to optimization services and digitally enabled features, today, there are endless options for mines looking to improve their screening operations

By Carly Leonida, European Editor

Standard, off-the-shelf screens and media panels will meet the requirements of many mining operations. However, as feed conditions change and companies look to exploit more complex orebodies, particularly those containing more moisture or higher proportions of clay minerals, the requirements for optimal performance become a little more complicated. Higher metal prices and elevated demand mean that many operations are also expanding and, when space is at a premium, customized screen models offer the opportunity to boost performance without altering the plant’s footprint.

Corne Kleyn, global product manager for screens at Weir Minerals, discussed the options and benefits of engineered to order models.

“We have a standard screen range that meets the requirements of the majority of our mining clients,” he explained. “But sometimes we have non-typical applications. For example, if the material contains high moisture levels or a high quantity of clay, it can be quite difficult to screen. Some mineral processing operations handle very abrasive or corrosive slurries and again, there are specific construction materials that can improve the life and performance of these machines. Engineered to order simply means that we will custom design a screen to perform very specific process duties.

“It also means, especially for brownfield operations that can have tight spatial requirements, that we can design a screen to fit that exact envelope. Often, standard machines simply won’t fit the available footprint.”

It’s a common misconception that customized machines are more expensive. When viewed from a total cost-of-ownership perspective, engineered-to-order models can offer better value for money as they are designed to withstand the stresses of a specific operation. A longer service life and, in some cases, better productivity mean the initial capital cost can be quickly offset.

Kleyn added: “We understand that it’s not always possible or commercially viable to design a screen from scratch, so we try to use standardized parts from our component design library wherever possible and then lay the screen out to fit the envelope. This lowers the initial cost and lead time and means that the mine has access to a wider range of spare parts when it comes to maintenance.”

Kleyn and his team have noticed an uptick in interest in engineered-to-order screens recently as the number of brownfield projects outweighs greenfields, which tend to have more flexibility in terms of plant layout.

What does the scoping process look like?

“The first thing we look at is the envelope for installing the screen, which gives us the 2D footprint,” he explained. “Then we look at the 3D space. A vibrating screen is a 3D piece of equipment, and it can be quite violent in the way it moves during operation. There will be certain tolerances for clearance, so we look at things like the feed and discharge chutes, the underpan, and if there are any structural items that would impede the installation of a standard machine.

“We also really go into the nature of the application. For example, there are a couple of things we might change depending upon the material, like the stroke. For certain feed gradations and aperture sizes, we will adjust the stroke. Operational speed is very important, as how fast you run the excitors affects the material travel rate.

“We also look at the material characteristics, bulk density, and top size as all of this will affect the deck load. The screen structure must be designed to support the mass of material that sits on the screen deck, and the slope angle can be adjusted depending on the cut size and gradation. Of course, there’s a lot more detail involved in designing a machine, but these are some of the basic parameters.”

Designed for Intelligence

It’s not an exaggeration to say that screens are one of the hardest working pieces of machinery on site. They must also withstand some of the greatest stresses. On average, these machines move through 14-17 fatigue cycles per second, operating 24/7. In just a few days, it’s possible for a machine to complete millions of fatigue cycles. Large screens can weigh in excess of 50 metric tons (mt), and they accelerate at 5G — five times the gravitational pull of the Earth. The loads these structures are subject to are phenomenal and their design requires an experienced engineering team.

“When you don’t know what goes into the design, it’s easy to take these machines for granted,” Kleyn said. “At Weir Minerals, over many years, we have developed our own inhouse design criteria based on industry research and internationally recognized standards. We design these machines for infinite theoretical life. But, in reality, machines don’t last infinitely because of wear. We use finite element analysis (FEA) simulations, and all the latest design tools, as well as advanced liners and parent materials during manufacture to ensure the longest possible life.”

Kleyn believes the future of screening lies in fully autonomous, intelligent machines that can monitor feed conditions using sensors and cameras and adjust their own operating parameters to optimize performance and energy usage. Although this vision is still a way off, steps are being made toward it through digital technology implementations.

Weir Minerals introduced its Synertrex IIoT-enabled platform for mining in 2018. The company offers specific modules for items including hydrocyclones and pumps, and, in 2022, it will be launching a module dedicated to screening.

“We’ve spent the last three years testing and refining the system and I’m extremely pleased with the results we’ve seen,” Kleyn said. “We’ll be announcing a case study with a mine in South Africa later in the year.”

The package will allow mines to remotely control and optimize all the usual parameters such as stroke, operating speed, acceleration, etc. and it also features advanced predictive analysis.

“We’ve spent a lot of time developing algorithms to accurately predict the remaining useful life (RUL) of components,” Kleyn said. “This can really help mines with predictive maintenance and replacing parts before they fail and cause damage or interruptions to production.”

At the moment, Synertrex technology is only applicable to Weir Minerals screens, but this may change in the future. Going forward, strategic Enduron machines will be supplied with the system as standard, but all new models will be “Synertrex enabled.” This means they are supplied with all the brackets and cable routing required to accept the sensors and devices, so the customer can add the Synertrex monitoring system at a later date if they wish.

“Going forward, we’re focusing our R&D efforts in three areas: advancing our knowledge of fatigue, developing and testing new welding methods, and materials science,” Kleyn explained.

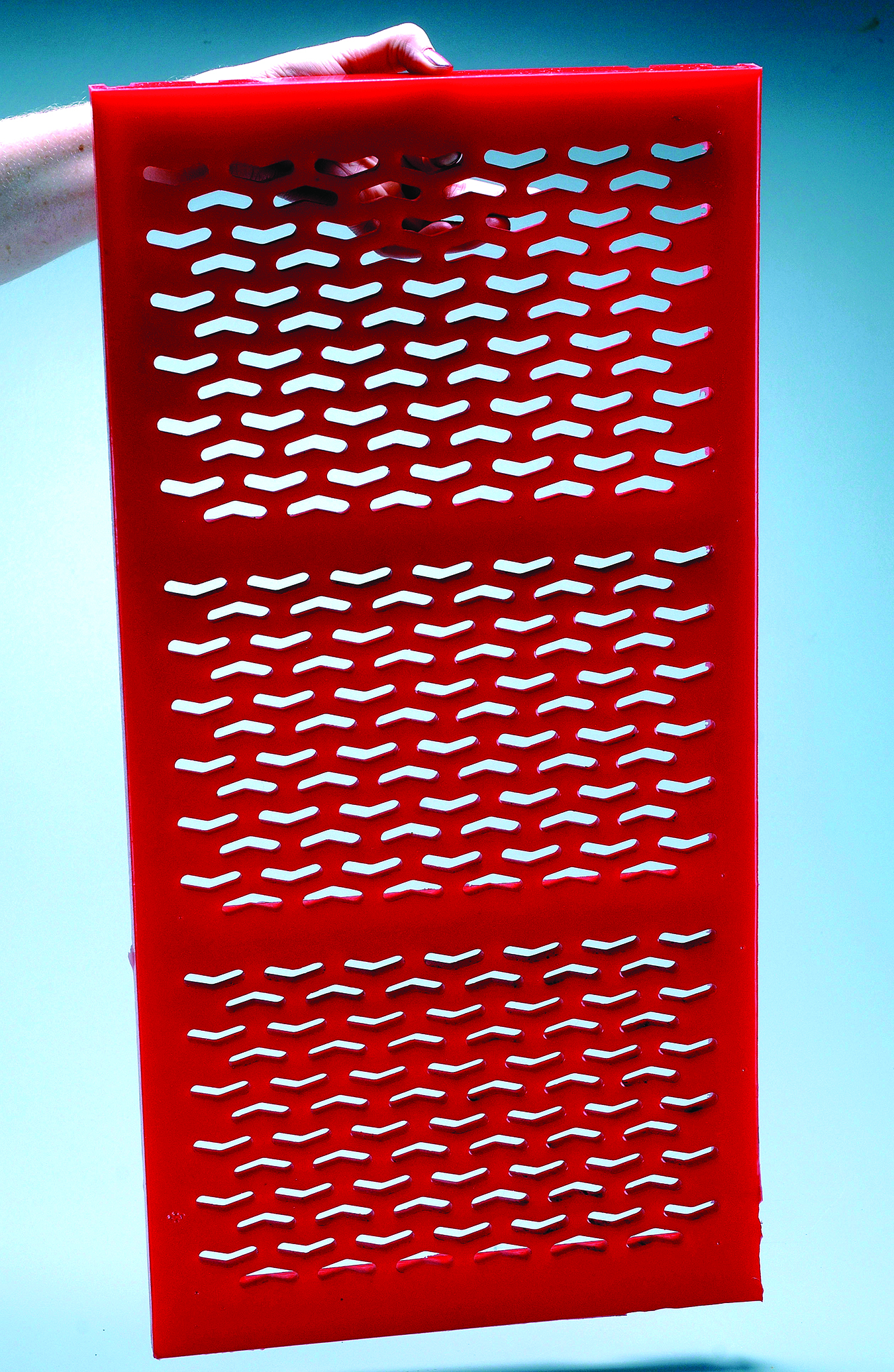

All screen media has the right relief angles and slot geometry for a specific application. The boomerang design shown here from FLSmidth is particularly well suited to screening iron ore. (Photo: FLSmidth)

Get the Most From Your Media

Screen media are a relatively small and inexpensive wear part when compared with the overall capital cost of screens, and they are often overlooked in the quest for optimization. However, poorly performing media can result in the loss of production, increased maintenance costs, downtime, and decreased product quality.

FLSmidth provides screen optimization services and field trials to generate personalized recommendations for screen panel media, size, aperture size and shape, position, motion, and other features. Shane McLoughlin, global product manager for screen media and trommels, joined the discussion.

“The performance of screen media will naturally change over time as the feed conditions change,” he explained. “Commonly this happens when there are changes in the composition of the orebody, changes to the size distribution of the feed or increasing or decreasing feed tonnages. This can all influence the performance of the screens. If the mine is unhappy with the wear life of their media, the metallurgical performance of their screens, or if the apertures are blocking or blinding, it’s time to call in experts for an assessment.”

FLSmidth supplies panels that are specifically designed and constructed to suit different operational conditions. The team aims to improve the overall performance of screening operations through applying the correct apertures and panel accessories, as well as open area and anti-pegging capabilities.

An initial assessment allows the team to gain an understanding of the screening operation and feed conditions. Particular attention is paid to inspecting the screen surface, assessing the wear life of the entire deck, and looking at how material selection and media accessories can influence the performance of the deck. The findings will point toward a solution, and simulation or trial work can then take place to prove the changes will provide the targeted benefits.

“Mines with highly variable orebodies, high abrasion or throughput constraints typically have opportunities to improve screening performance,” McLoughlin said. “Screening performance tends to fly under the radar until there is an issue downstream that has been influenced by misplaced ore turning up in the wrong parts of the circuit.”

Misplaced material in downstream processes is common and can cause overloading of other processing operations that can reduce overall mine recovery and profitability. Maintaining a balanced operation naturally improves productivity. From an environmental perspective, efficient screening and dewatering reduces the chance of spills in the process circuit, and increased wear life decreases waste.

“Increasing the service life of screen media naturally improves productivity by reducing the frequency and amount of maintenance people are required to perform,” McLoughlin said. “Recovering more mineral by optimizing your screening, without changing other processes generally provides fast payback.”

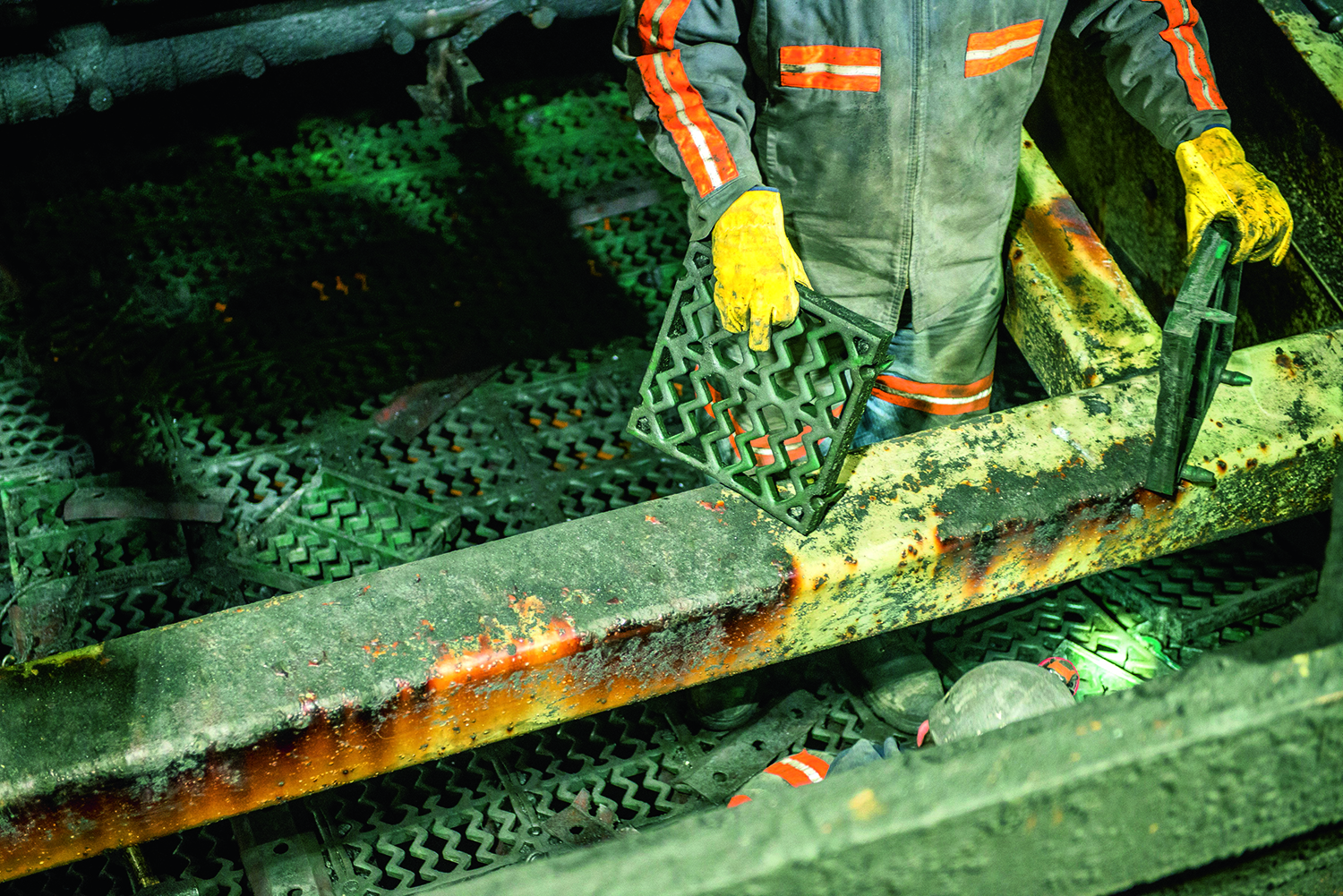

Polydeck panels in operation at the Sugar Camp coal mine in the U.S. (Photo Polydeck)

Improving screening efficiency by only 1% can provide significant benefits, for instance, by reducing regrinding in the primary milling circuit. Improving wear life also reduces operational costs through consuming less screen media and comes with the bonus of lengthening maintenance cycles and subsequent improvements in occupational health and safety that will both add to the payback in time and money.

McLoughlin added: “There is currently a lot of interest in reducing maintenance frequency so that owners can keep their plants in operation for extended periods of time. Improvements in aperture design and new optimized materials of construction are gaining increasing recognition as enablers in achieving that aim.”

Optimization in Action

FLSmidth’s screen optimization service recently helped a large gold producer in Western Australia to improve the availability of its semi-autogenous grinding (SAG) mill discharge screens and boost the life of its screen decks.

The screen decks were continuously loaded with highly abrasive ores that had a top size greater than 30 mm (1.18 in), and the screen media did not last the target wear life needed for the desired screen availability. Frequent shutdowns for screen panel replacement led to high maintenance costs, safety risks for maintenance technicians and low equipment productivity.

FLSmidth performed a screen media optimization analysis to determine the best type of media for the customer’s process. This took into consideration the strengths and weaknesses of each type of media as well as customer-specific factors such as mineral characteristics and properties, operating conditions, throughput, and other aspects of the process.

The team ran scenarios to compare media types and make a recommendation. The analysis showed that the optimal screen media was a new grade of polyurethane material that FLSmidth developed working with a trusted prepolymer supplier. The material combines the most desirable properties of rubber and polyurethane elastomers for a longer wear life.

FLSmidth proposed a trial to compare the polyurethane panels with the rubber media that the mine was using. Trial panels were installed with the polyurethane media in the feed, center and discharge ends of a SAG discharge screen to assess its performance in different positions. The test polyurethane panels were dimensionally identical in aperture size, aperture positioning and open area to the existing rubber panels to offer a fair wear rate comparison.

The SAG mill was shut down every eight weeks for wear rate inspections. The polyurethane and rubber panel wear rates were monitored for ligament loss and the final weight and volume losses were quantified. The trial duration was 30 weeks.

During the 30-week trial, one-fifth of the rubber panels were replaced, but all the polyurethane panels had additional wear life left. The polyurethane panels had a 10–20% longer wear life than the rubber panels. The feed type, hardness and abrasive properties of the ore would traditionally demand rubber screen media, but the new grade of polyurethane that FLSmidth uses changes the expectations for what polyurethane can achieve.

The improvement in media wear life lowered the amount of time maintenance personnel were required to spend on the screens. The customer benefited from increased safety and decreased maintenance expenses, meeting their goals for the trial. Maintenance personnel noted that as the polyurethane panels wore, the apertures retained their profiles longer and with less scalloping than the rubber panels.

The customer went on to convert the full deck of the screen to the polyurethane panels, and the improved aperture integrity and resulting sharper cuts increased the plant’s screening efficiency. FLSmidth proudly reported that similar material optimization trials in other applications, including trommel panels, have given similar results, with up to three times wear life.

Looking to the Future

Historically, monitoring the health of screen media panels has been a challenge for operators. U.S.-based specialist, Polydeck, is working on solutions to address this.

Ryan Johnson, director of R&D, and Trey Rollins, director of marketing, spoke more on this.

“Our research has led us to focus on three primary concerns operators have in relation to the reliability and availability of their screen media,” Johnson explained.

“The first concern revolves around the reliability of screen panel fastenings. Operators need to be confident all screen media panels are securely fastened during installation and remain fastened during operation. Displaced screen panels can block material flow, send misplaced material through the process, and potentially damage equipment. Our technology ensures an operator can detect fastening issues before a panel becomes displaced and alerts an operator so that action can be taken quickly to prevent contaminated product piles.

“The second concern centers around screen availability in relationship to media performance and wear life. The media health technology designed into our panels will help operators more precisely understand the wear life of a screen panel and be able to plan maintenance activities based on the predicted life of panels in service. The ability to measure panel wear level in real time creates an opportunity to optimize screen media selection by location on the deck and develop media maintenance plans that balance cost and performance. The ability to detect specific panel location gives an operator insight into specific wear patterns and opportunities to drive efficiencies throughout their process.

“Third, our concerns centered around screen media being installed in the proper location on a screen deck. Due to screen decks often having two or three different aperture-sized panels on a screen, operators need to be confident that all media panels are placed in their proper location. The correct placement of the media ensures an operator is set up to achieve their target separations and maximize efficiencies.”

Today, media panel wear is managed through manual tracking processes and visual inspections. Product gradations taken after material is screened also provide an indirect measure of panel condition but serve as a lagging indicator of the wear a panel has experienced. In reality, screens are often difficult to access, and visibility of the panels is minimal, particularly on lower decks.

Moreover, a thorough inspection of a screen wear requires both a machine shutdown and a dedicated person to perform inspections and take measurements, making visual inspections expensive and time consuming. Typically, the best information an operator has at their disposal is a historical record of service intervals and changes made to a screen.

The advent of “smart panels” i.e., those embedded with sensors to help operators monitor, manage, and measure the performance and wear life of their screen media in real time via the IIOT, could prove a useful alternative.

Smart Panels, Smart Operations

In a presentation at the MINExpo 2021 tradeshow, Polydeck’s experts explained that there are two different types of critical information that smart panels could provide. First, information on tracking long-term usage and performance patterns of the screen media. Data used for this include the age of the panel, the wear level and the physical location. The goal is to use this data to build predictions of wear life, and in turn, predict when maintenance might need to be performed or replacement parts ordered. This information can be used to optimize maintenance planning, avoid stock-outs, and ensure the most efficient use of screen media.

Second, detection of critical events that may require an urgent response. For instance, the dislocation of a screen panel or an impact that breaks or punctures the screen media. Today, if a panel comes loose or fails catastrophically, operators often don’t know until it’s too late. Using embedded sensors to connect operators with the screen panels could help users avoid costly downtime and repairs and reduce the chance for misplaced material within a circuit.

Rollins said: “We believe that integrating digital technology into media panels will be a key part of screen management practices in the future and will help further increase efficiencies throughout the material processing process.”

To date, the Polydeck team has focused on testing and proving out the key technical building blocks of the digitally connected smart panels. The first step has been to create and embed unique digital identification numbers into each panel. Assigning unique embedded identification numbers will allow panels to be traced, and the team is working to couple this capability with wear level monitoring. Over time, the aim is to provide producers with a digital visualization of each individual panel on a screen deck or machine in order to determine how long each panel has been in service and its wear rate. This will give a more complete understanding of the overall cost of screening in an operation.

“In 2022, our focus will be on testing larger installations of the panels with an emphasis on building the communication infrastructure necessary to connect all the screen panels on a machine or deck,” explained Johnson. “We will also continue exploring the use of data collected from the panel sensors to predict when critical events may occur on a screen deck.”

Of course, there are challenges with introducing electronic devices into a product that is constantly subjected to severe vibration, heavy impact and abrasive wear. However, the advancement of sensor technology in the last 10-20 years has resulted in very robust designs that deliver the technical requirements needed to incorporate sensors in a panel that can perform in extreme environments.

“Still, there are some significant connectivity challenges associated with the use of sensors in screen media panels that we have had to resolve so that hundreds of individual screen panels can be identified on multiple screens across an entire processing plant,” Johnson said.

“Our first goal is to ensure screens are set up with the media that will provide optimal production and secondly, to minimize the resources required to manage screen media health. The feedback provided through our smart system will allow operators to select screen panels that optimize the balance between production rates and media wear life. Additionally, it will automate the processes of reordering screen media and planning for media changeouts.”

Screen media panels have the unique opportunity to momentarily interact with almost every particle that passes through a processing plant. And, by integrating sensors into media panels, there is also a chance to provide operators with intelligent insights regarding the nature of the materials passing through the screening stages of their processes.

GK displays its STM-SCREEN Two-mass single-deck Vibratory Screen at MINExpo 2021.

Two-mass Screening System Attracts Attention

General Kinematics displayed an STM-SCREEN two-mass single-deck vibratory screen at MINExpo 2021. “That was a very good show for us,” said Derek Kerkera, market director for mining at General Kinematics. He attributed the success to putting a larger mining-class machine on the show floor. The STM-SCREEN showed mining professionals that General Kinematics is serious about mineral processing, Kerkera explained.

“We demonstrated a lot during the show, specifically with starting and stopping the STM-SCREEN, which you do not see many screen manufacturers do, because of the violent nature of shutdowns for brute force machines,” Kerkera said. “Our equipment uses GK’s proven two-mass, natural frequency drive design, and the smooth starting and stopping caught a lot of eyes.” Editor’s note: The two-mass design was discussed at length in Vibratory Screens, May 2021, E&MJ.

So much so that a silver miner from the western U.S., who spent a substantial amount of time gathering information at the General Kinematics stand, informed GK that he had placed a hold on a previous screen order with another manufacturer. “He asked us if we would be interested in doing the project,” Kerkera said. “He wanted to test the mine’s material first — a service that General Kinematics provides. GK received ore samples within three days of the show, and we tested the material. The silver miner liked the results, canceled his other order, and gave us an order for two 4285 STM-SCREEN.”

The STM-SCREEN, bolted together, breaks apart along its centerline. The exciter that sits above the machine splits the same way. At the end of MINExpo, the team at General Kinematics broke that 60-ton machine down into halves, loaded it on to trucks, and shipped it to the Copper Mountain mine in British Columbia.

Part of GK’s success stems from learning about the material properties of the mine. Samples sizes for testing vary, but General Kinematics can get a good test from six 55-gallon drums. “We run the sample on a 1-ft wide machine using the same bed depth as a normal operation,” Kerkera said. “We replicate what they want to do in the field.”

The object is to get a uniform flow rate across the screen. The residence time on a two-mass screen can be 25-32 seconds or more, Kerkera explained, where the material feeding on to a banana screen might have a residence time of eight seconds. “When we achieve separation early in the process, we can use the second half of the screen deck not only for extra separation but dewatering at the same time,” Kerkera said. “A banana screen doesn’t even really start to do efficient screening until the material reaches the discharge end. At that point, there’s no space to dewater.”

Screening machines are located at the discharge of a SAG Mill. For an HPGR application, they can be found on both sides. “With HPGR, they will handle the dry side and the wet side,” Kerkera said. “The SAG mills feed directly on to our flat ceramic-lined load plate.”

During a test, General Kinematics looks at various combinations of stroke and velocity to determine optimum operating parameters. “We will try different bed depths, such as 1 to 3 in., to determine where the ore screens more efficiently, and then we look at the required length of the deck,” Kerkera said. “We are often conservative in our analysis, so when we say it will take 20 feet to screen it, it could probably be done with 15 ft. Even with our conservatism, we are finding that the Two-mass system is about 40% more efficient than standard brute force equipment.”

Higher capacities with better screening efficiency offer an exciting value proposition. In some cases, General Kinematics can place a smaller system where a larger screen was specified. A plant might maintain design capacity with one screen instead of two.

GK is now using variable frequency drives (VFDs) to hold the stroke constant all the time. “These machines can maintain the stroke no matter the inflow. That’s why we are seeing that 40% difference,” Kerkera said.

The stroke goes down with brute force screening machines as more material is fed on to the deck. In some cases, a mine might adjust to a 0.625-in. stroke because the 0.5-in. stroke runs at 0.375 in. once loaded with ore. “We start at 0.5 in. and stay at 0.5 in.,” Kerkera said. “The bed depth could be 1 ft, and the stroke would still be 0.5 in.”

That’s particularly important with SAG mills as they occasionally burp and flood the screening machine with ore. “Brute force machines don’t care for that,” Kerkera said. “The stroke drops to almost zero. The machine stalls, and they must shovel the material off the screens. Our screens will handle it. We have buried our machines above the trough during testing, and they operate as designed. That’s another huge advantage to the two-mass design.”

Word has spread about the STM-SCREEN and its two-mass design. Kerkera said miners from Central and South America had contacted General Kinematics. “Miners have requested our presence in Peru, Argentina and Chile, and at multiple locations in Mexico,” Kerkera said.

Seeing the interest take hold is fantastic, Kerkera explained. “In the past, we won a lot of business on brownfield work because we can provide a custom screening solution that fits into any footprint,” Kerkera said. “Now, engineering firms are specifying our STM-SCREENS for new plants and expansion projects.”

The General Kinematics team is available worldwide and ships screens to miners in Australia and Oceania from its facilities in China out of the port of Shanghai. Another facility in Italy supports Africa, Europe and the Middle East. “We have invested money and time, especially with training for personnel, to get those fabrication facilities to the standards our customers expect,” Kerkera said. “Many of the STM-SCREEN operating in Australia were fabricated in China, and several have been operating for six or seven years now and are still going strong.”