There’s an old, old saying that “water always wins,” alluding to the relentless pressure and seemingly infinite routes that water uses to work its way into places where it isn’t wanted. One of those places where it’s definitely unwelcome is any mining area that requires dry ground and stable walls. It’s often a constant battle to stay on top of groundwater inflows, and even though it’s usually accepted that water will eventually “win” almost every contest, pump builders go to great lengths to make sure it won’t happen while their units are running.

Several of these manufacturers took the opportunity offered by this year’s bauma trade show, held in Munich, Germany, in April, to introduce new models for mine-site dewatering applications. And more recently, Wilden conducted an online press event to unveil new, energy-saving technology for its popular air-operated double-diaphragm (AODD) pump line.

Building on BIBO

At bauma, Xylem unveiled a new submersible dewatering pump range comprising four new pumps ranging from 4 to 18 kW. The new units, according to the company, are specifically designed for water removal in mining and other extremely harsh dewatering conditions and are modeled on the popular Flygt BIBO unit. Xylem also introduced a powerful and compact Godwin pump specifically designed for lower-head dewatering applications.

Flygt BIBO Model 2870.

Flygt BIBO Model 2870.

More than 1 million of the original Flygt BIBO pumps have been sold since they were introduced in the 1960s, according to Xylem, and the new Flygt BIBO range incorporates several proven design features taken from the original dewatering pump, as well as new enhancements that give the pumps improved wear resistance and uptime capability. The new Flygt BIBO series, said the company, has been specifically designed for the toughest dewatering environments.

Daniel Westin, product manager at Xylem, said, “Xylem’s new Flygt BIBO includes several innovations such as our DuraSpin hydraulic system for unmatched wear resistance, a new plug-in seal and a single impeller-adjustment screw. All of these innovations work together to deliver our customers a pump with high uptime capability and a limited and low-cost service requirement.”

Xylem’s new Flygt BIBO is available in four models—the 2830, 2840, 2860 and 2870—capable of handling flows of up to 100 l/s (1,600 gal/min), heads up to 80 m (300 ft) and solids up to 12 mm in diameter. They’re available in power ratings of 3.7 to 18 kW (5.9 to 27 hp).

Xylem’s Flygt BIBO range will be available worldwide starting in the fall of 2013.

The company also showcased its Vac-Prime range, which automatically primes and re-primes from dry conditions. All units have single-stage end suction centrifugal pump ends, capable of handling solids and fitted with high-pressure double silicon carbide, oil bath mechanical seals, which allow the sets to run dry. Priming is done by a high-volume, belt-driven vacuum pump and float-actuated air/water separation system incorporating scrubber tank and coalescing unit. Cast iron construction is standard with stainless steel available as an option.

In addition, Xylem noted that it is expanding its dewatering pump rental offering across Europe to cater to a growing demand from the mining, construction and other industrial market sectors. Xylem said it will increase its bank of surface and submersible pumps through an aggressive rental branch rollout scheduled over the coming years including refurbishment of existing premises, new locations and via selective acquisitions.

Xylem said it is making the move after experiencing a growing need for expert providers of complete, turnkey dewatering solutions as well as for dewatering pumps to rent. Andrew Jones, head of Xylem’s dewatering business, said, “We have noticed an increased demand within the industry for dewatering services to be supplied as a complete package including pump and water treatment systems, engineering expertise and project management. This limits customers’ administration and management efforts, and provides peace of mind as they are contracting dewatering experts to take care of the job.”

High-head Units for Europe

In another Europe-related development, Weir Minerals recently introduced the latest edition in its range of Warman centrifugal pumps, the DWU dewatering pump, to the European market.

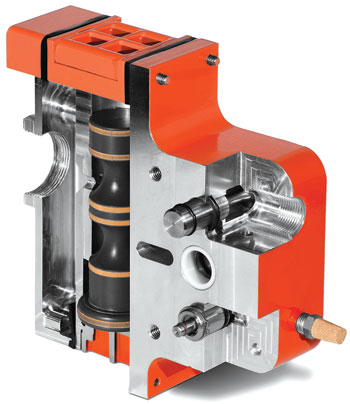

Cutaway diagram of Weir Minerals DWU dewatering pump.

Cutaway diagram of Weir Minerals DWU dewatering pump.

The pump is designed to deliver increased efficiency where water must be lifted to great heights—and the unit delivers efficient operation at heads of up to 140 m. Four sizes are available, with outlet diameters of 75 mm, 125 mm, 150 mm and 200 mm. The company noted that about half of the parts used in the new design are interchangeable with Weir Minerals’ popular Warman WBH slurry pump to help clients simplify spare parts ordering and holding.

Weir said its engineers designed a new, double-volute casing that reduces radial load and is capable of maintaining internal pressures of up to 7,000 kPa, allowing the pumps to be configured in series to deliver even greater head heights.

Steve Sedgwick, the Weir Minerals Europe product manager for mine dewatering, said, “The dewatering system is a crucial part of almost every mining operation around the globe, and we’re committed to ensuring that our range of dewatering pumps is broad enough to deliver optimum efficiency, whatever the requirements.

“We have used the latest computer-modeling technology to achieve a hydraulic design that is optimized for the high-head, high-efficiency dewatering challenges most commonly encountered by our customers, while maintaining a proper robust mining type pump. The DWU is designed specifically with heavy lifting in mind, so it minimizes hydraulic loads on the internal parts, maximizing efficiency and increasing the longevity of wear parts.

“Mechanically, the pump has been designed with heavy-duty mining applications in mind. A one-piece frame ensures it stays correctly aligned while ultra-heavy-duty bearings maximize wear life and reduce the whole-life cost of ownership.”

Other notable features of the DWU include a thrust reduction impeller design to minimize axial thrust loads; external fans to keep bearings cool; and an impeller release collar on larger models.

Smart Enough to Save Energy

Sulzer Pump launched its next generation of dewatering pumps, designed for harsh conditions in mining and touted as a pump line “made for the real world.” Available in two series, one for drainage (model XJ) and one for sludge (model XJS), Sulzer refers to this ABS submersible pump range as the “world’s smartest,” equipped with electronic technology that can potentially save energy, reduce wear, and allow pump condition to be checked without disassembly. According to Sulzer, the pump line’s AquaTronic unit integrates electronic intelligence into the pump, while its AquaPlug control and monitoring module integrates it into the power supply.

Sulzer XJS sludge pump.

Sulzer XJS sludge pump.

With AquaTronic in command, pumping starts immediately at full capacity and runs consistently. The direction of impeller rotation is always correct, because AquaTronic electronically compensates for incorrect phase order—a feature claimed to be a first among dewatering pumps. In addition, the unit eliminates unnecessary servicing. With the pump line’s USB link and a connected PC, diagnostics can be performed without disassembly.

AquaPlug provides a range of control and monitoring functions, including automatic stop/start, optional level control, alarms and service indication. Although the pump can run continuously, AquaPlug can also be set to stop it when it begins to snore. By stopping at dry running and starting automatically at a specified level, energy use can be optimized and wear can be reduced.

Less Air, More Product

California-based Wilden Pump & Engineering, a member of Dover Corp.’s Pump Solutions Group and major supplier of AODD–type pumps, recently announced the launch and availability of the new Pro-Flo SHIFT Air Distribution System (ADS) for its Advanced Series bolted and Original Series clamped AODD pumps. The Pro-Flo SHIFT ADS, according to the company, represents a significant breakthrough in energy efficiency within the AODD pump category, claiming its innovative design will enable Wilden AODD pumps to achieve up to a 60% savings in air consumption over competitive AODD pump technologies, while providing more product yield per standard cubic foot per minute (SCFM). (See sidebar for additional details.)

Wilden AODD model.

Wilden AODD model.

“The Pro-Flo SHIFT represents a giant leap forward in the energy efficiency and performance of AODD pumps. The simple design of the ADS doesn’t require any additional bolted-on equipment or bulky electronics, allowing operators to keep the same compact footprint,” said Chris Distaso, director of engineering for Wilden.

The Wilden Pro-Flo SHIFT is available in 38 mm (1-1/2 in.), 51 mm (2 in.), and 76 mm (3 in.) sizes and features maximum discharge pressures up to 8.6 bar (125 psig), maximum flows up to 923 l/m (243 gal/min) and maximum solid-handling size to 13 mm (1/2 in.). The Pro-Flo SHIFT is available with maximum suction lifts to 7.2 m (24 ft) dry and 9.6 m (31 ft) wet.

In an online product introduction held for the trade press, Wilden’s technical staff noted that the Pro-Flo SHIFT not only significantly improves energy efficiency, but also costs 50% less than an electronically actuated ADS, is submersible, and features plug-and-play operation. Its robust design makes the Pro-Flo SHIFT ideal for use in harsh operating environments and includes ATEX compliance for use in potentially explosive atmospheres. The Pro-Flo SHIFT has fewer operating parts, which equates to less downtime and simple maintenance. With no electronics, its design is well suited for the harsh environments typically found in industrial applications.

How Wilden’s New ADS Works

In a recently released white paper, Wilden pump engineer Carl Glauber pointed out that, since its introduction about six decades ago, AODD pump technology has gained a reputation for outperforming other positive-displacement pump styles in demanding liquid-transfer applications because the design characteristics of AODD pumps enable them to run dry, maintain a suction lift up to 30 ft (9 m), withstand deadhead conditions without damage, operate while completely submerged, and pass solids up to 1-3/8 in. (35 mm) in size, all while meeting most flow requirements and requiring little maintenance.

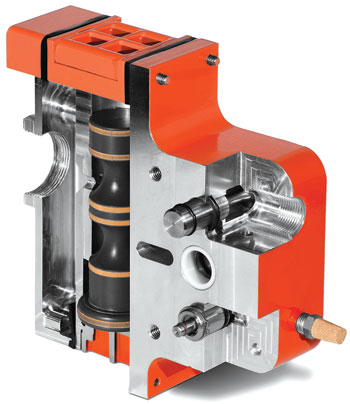

Cutaway of Wilden’s new Pro-Flo SHIFT Air Distribution System.

Cutaway of Wilden’s new Pro-Flo SHIFT Air Distribution System.

While the basic operational characteristics of an AODD pump have remained constant for the past 60 years, suppliers have made improvements in the pump’s air distribution system (ADS) that address its rate of air consumption in relation to the product flow rate and how much air can be wasted during the pumping cycle—with that wasted air resulting in an added cost for the site operator. While these savings are important for the operator, they are actually modest when looking at the total volume of air that is used for these pumps.

According to Glauber, there remained an opportunity for more significant savings. Specifically, during the time period from the end of each stroke to the completed shift of the valve, air is allowed to “overfill” the air chamber without any corresponding displacement of fluid. The rate of this “overfilling,” which is defined as wasted compressed air, should be more adequately controlled.

A recent generation of ADS designs has attempted to eliminate overfilling in AODD pump operation by cutting off the air supply to the air chamber before the end of the pump stroke. Glauber said there are two shortcomings, however, in this approach. First, this ADS technology is electronically monitored and controlled, rather than mechanically actuated, which raises an entirely different set of energy usage, maintenance and operational concerns.

Second, electronic ADS technology requires time to “learn,” meaning that every time the pump is turned on, the electronic system needs 30–40 seconds to monitor the operation of the pump before it can estimate when to cut off the air supply prior to the end of the stroke. This can result in erratic and inconsistent flow rates for up to 40 seconds and a corresponding waste of air, a drawback that is compounded in dosing operations that feature constant on-off cycles.

Wilden’s Pro-Flo SHIFT Air Distribution System instead restricts the air flow into the air chamber near the end of each pump stroke so that only enough air is introduced to keep the pumping process going. This is accomplished through the incorporation of an air control spool that automatically meters the air to prevent overfilling with no reduction of product yield. The result is reduced air consumption while still maintaining maximum operational efficiency and flow rates.

This mode of operation eliminates the need for the operator to manually adjust the pump for efficiency since the ADS automatically does it. This creates a new efficiency point in AODD pump operation, highlighted by improved energy use with no loss of flow rate.