Development and blast applications for Resolution Copper’s No. 10 shaft

Sinking what is now the deepest single-lift shaft in the U.S., Resolution Copper is using brute force engineering to finish the project.

In 1995, one of the great copper ore discoveries of the last 100 years occurred in the heart of Arizona’s Copper Triangle, and today the Resolution deposit represents one of the largest undeveloped copper resources in the world. The ore body is estimated at 1.3 billion tons with a 1.5% copper grade. The discovery was made by Magma Copper Co. during exploratory drilling. In 1996, the company, along with the Resolution deposit, was acquired by BHP Copper. Shortly after the acquisition, BHP ceased mining operations at the Magma Copper mine, near Superior, Arizona, and did not pursue further exploration.

Diagram of vertical shaft muckers (VSMs) with a clam style bucket and pneumatically powered.

Five years later, Kennecott Exploration signed an earn-in agreement with BHP Copper and initiated a five-year drilling program to further identify the size, grade and boundaries of the porphyry deposit. During this time, Kennecott Exploration transferred all its assets and interests in the project to Resolution Copper Co., a Rio Tinto subsidiary. By May 2004, Resolution Copper Co. had met all the terms established in the earn-in agreement.

Today, the Resolution Copper Project is operated by Resolution Copper Mining, a 55:45 Rio Tinto-BHP Copper joint venture. Rio Tinto is the managing partner of the joint venture. In 2006 Resolution Copper teamed up with sinking contractor Cementation USA to sink what is now the deepest single lift shaft in the U.S., the Resolution Copper No. 10 shaft. Resolution Copper is developing a panel caving operation to mine the deposit and the No. 10 shaft will serve as the primary access point for the operation.

The development work for the No. 10 shaft began in February 2007 with collar construction and surface set up. Real sinking started in January 2009. During the best of times, production was averaging 9 ft per day (ft/d) and by 2012 the 28-ft-diameter shaft had reached more than 1-mile deep. The crews sinking the shaft use a Galloway work stage, which allows the miners to do all of the work with a high degree of automation, withdraw during the blast, and then quickly return to the bottom and repeat the cycle. The five-deck work stage has four jumbo drilling machines, two shaft mucking machines, a concrete pouring system, and all of the tools needed to advance the utilities (pipelines, electricity, etc.).

Production was moving along swiftly and then they hit water—lots of water and it was hot. The mining engineers had accounted for high temperatures at depth, but they had not anticipated water. The miners adapted blasting practices to a 5-ft benching plan. Production slowed as conditions grew more intense. Knowing they would eventually have to bring air conditioning and ventilation systems online for full-scale mine production, Resolution Copper has moved those plans forward. At the end of 2013, the heat became an unacceptable working condition and the decision was made to cease operations until the new cooling system was put in place. They are completing that system now and shaft sinking operations are expected to begin again this summer.

Modern Shaft Sinking Techniques

Bulk and packaged emulsion non-electric and electric detonators.

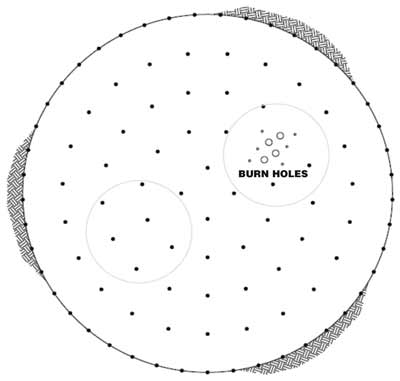

Resolution Copper No. 10 shaft full bench blast pattern plan.

Similar to all mining projects, shaft-sinking operations require a lot of dedicated people to be successful, explained Tom Goodell, general manager-shaft development for Resolution Copper. A photo of all of the people working on the project was taken before Resolution Copper lowered the Galloway work stage into the shaft in 2008 and most of those locally trained people are still with the project today. “The No. 10 shaft is currently at 6,630 ft, already the deepest shaft ever sunk in the U.S., and we still have 312 ft to go,” Goodell said. Before joining Resolution Copper, Goodell spent five years as general manager for Macintosh Engineering and he also worked for 10 years with J.S. Redpath, as general manager of U.S. operations. All-in-all, he has participated in the design start-up, operation, and management of six large scale shafts and underground construction projects.

The shaft-sinking production cycle consists of drilling, loading the holes, blasting, mucking, initial ground support, concrete lining, and the installation of utilities (pipe). “We have an overall setup that is designed to accomplish each of these cycles efficiently,” Goodell said. “The key to it is a Galloway work stage.”

The Galloway work stage remains near the bottom of the shaft most of time. Embedded in the work stage are jumbo drills, mucking machines and the equipment for lining the shaft. “Almost everything we need is down there on this 160-ton, suspended-from-the-surface work stage,” Goodell said.

Drilling is accomplished by four fit-for-purpose drill rigs or jumbos. A jumbo with control console is lowered from the Galloway to drill a number of concentric holes. “The jumbos provide a high degree of accuracy,” Goodell said. “You could not do this type of work with hand-held pluggers.”

Once the round is drilled, plastic tubes are inserted into the holes to prevent water and cuttings from entering the holes. The larger burn holes are not loaded giving the round a free face to break to during detonation. “The burn cut works quite well,” Goodell said. “The blast goes straight up into the bucket well in the Galloway and doesn’t do much damage to the structure. That’s the theory at least; the miners still seem to break things every once in a while.

“We could pull 12 ft rounds in this rock, but we decided on 10-ft rounds because it fits our cycle,” Goodell said. “We want a cycle every day. Two rounds equate to one 20-ft concrete pour.”

For blasting, Resolution Copper uses both bulk and packaged emulsion. Once they hit the water, they needed to use only packaged emulsion. Trim powder is used along the perimeter to reduce overbreak of the rock. The blast is designed in such a way to reduce the energy going into the wall, which also lowers the concrete costs.

“We remind the miners not to spill the emulsion when they are loading the holes,” Goodell said. “That is usually the primary source of the ammonia smell after the blast.”

A single electric cap detonates a round tied to non-electric initiators. Reversible air ducts within the ventilation system, which normally blows chilled air into the bottom of the shaft, are used to pull the fumes out of the shaft so that the miners can get back to work as soon as possible after the blast.

Two 1/3-yd3 pneumatically powered muckers—everything on the Galloway is pneumatically powered—load 14-ton buckets. “These muckers are suspended from the work stage and the miners get pretty good at operating these units,” Goodell said. “We do not hoist the muck all the way to the surface. A tunnel intercepts the shaft at about the 1,100 ft level and the muck is transported by rail to Superior.”

For initial ground support, which protects the shaft miners from falling rock prior to the installation of the concrete liner, the shaft sinkers have generally moved away from rock bolts and mesh to fiber reinforced shotcrete. “We are using high, early strength shotcrete with poly fibers,” Goodell said. “We no longer bring shotcrete or concrete down by slick lines (pipes), we use a fit-for-purpose bucket. The system works well and it has decreased development time. And, the miners do not miss hanging on those jacklegs too much.”

Concrete is lowered by the same buckets and the miners pour a 20-ft jump form. “When the miners break the 25-ton mains on the form from the previous pour, the reaction is rather violent as the form weight is transfered to the Galloway stage causing it to bounce a bit before it settles,” Goodell said. After the pour, a total of nine pipes (water discharge, intake of chilled water, ventilation, compressed air, service water, etc.) are installed on the shaft liner.

The production strategy was to blast once a day. Mucking took about six hours before they hit the water. Now it’s a whole different situation, because the miners have to stop and dewater. On a regular full-face shaft round, the miners would muck the round on swing (afternoon) shift and drill and blast on the graveyard shift. Shortly after detonating the round, the miners start lowering the form. Day shift is all concrete work and if they are not pouring concrete they are advancing pipe. Ideally, that amounted to 10 ft/d of advance. Now that they have encountered water, they would be happy to get 5 ft/d and they have 312 ft to finish the shaft.

Brute Force Engineering

From initial startup until the end of last year, production was moving along as planned, if not better than planned, and then productivity flattened out at 6,500 ft. The reason: hot water. “In late December, we hit a lot of water,” Goodell said. “We are pumping 460 gpm. If you had asked me five years ago if we could sink a shaft with that much water coming into it, I would have said no. But, we are figuring it out.” The other wrinkle is that the water is coming out of the ground at shaft bottom at as high as 170°F (77°C).

“The consultants told us that we would have little or no water below 4,000 ft,” Goodell said. “They kind of missed that call. We hit it all in one spot and it was quite dramatic.”

The high temperatures have not affected the reliability of the explosives. “We have had no major consequences,” Goodell said. “We use a long thermometer to measure the temperature at the bottom of the blastholes and, if we have holes at 175°F or more, we do not load them. There is never more than three or four per bench. We are watching it carefully.” Resolution Copper is also working with suppliers to develop explosives that can handle the higher temperatures.

Most of these locally trained miners are still with the project five years later.

The ventilation system for the shaft-sinking operation used refrigerated air to cool the miners as they worked. That system, however, was designed for hot rock, not hot water. “As a result of the heat load coming into the shaft, we have had to suspend shaft-sinking operations and upgrade the ventilation by as much as three times,” Goodell said. “It just got too hot down there.” A thermal image of the miners working with water coming out of the rock illustrates the hellish conditions.

Thermal image of drilling grout holes (note hot water leaking from walls).

Resolution Copper had already planned for a large cooling system for the ultimate 120,000-t/d mine. “We are now adding that system sooner than later,” Goodell said. “We will more than triple our cooling capacity and increase the ventilation by 180%.”

Resolution hopes to restart sinking operations soon (June 2014). As Goodell explained: The heat was not a surprise, but the water was. The miners at Resolution Copper have a massive operation to build. They have 312 ft left to finish this phase and they are looking forward to completion.

This article is based on a presentation Tom Goodell delivered on February 12, 2014, at the ISEE Annual Meeting in Denver, Colorado, USA.