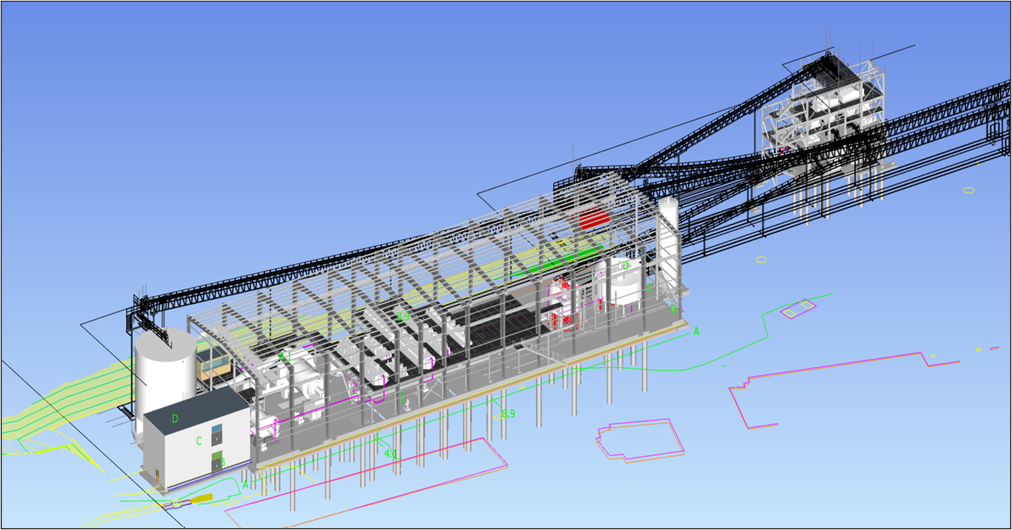

Mill Building and Crusher Tower, to be located in Bunker Hill Yard, looking West

Bunker Hill Mining Corp. is finalizing the engineering of the processing plant, and the company has now restarted construction work at the site, located near Kellogg, Idaho, USA. It is on schedule and budget to restart mining operations by the end of 2024.

The company has hired GMS Mine Repair and Maintenance to upgrade the Russell Portal, which provides primary access to and egress from the initial mining areas at Level 4 of the underground. The portal will be expanded from 10- x 10-ft to 16- x 16-ft to better facilitate haulage and vehicle passage during operations and is expected to be completed by early September 2023.

This will be followed in phases, over 6 months, by refurbishment of the existing underground ramp between the 6 and 8 Levels, geotechnical stabilization of the ramp as it cuts through the Cate Fault between Levels 5 and 6, installation of final ventilation support, establishment of key underground facilities such as the maintenance shop, connecting the underground mine to the power grid, and definition drilling of initial mining areas.

Bunker Hill purchased a ball mill capable of expanding production throughput capacity from Barrick’s Golden Sunlight mine. Transport to Bunker Hill site is planned during Q3, which will enable the process plant engineering team to repurpose it as part of an upgraded comminution circuit.

Increased extra capacity provides the mine planners with an immediate upside opportunity to improve upon the economics of the existing 1,800 tpd restart plan and is being investigated as part of an ongoing business plan optimization process.

Barr Engineering continues to advance final detailed engineering for the processing plant and expects this to be 100% complete in Q3 2023. The advanced status of this work has allowed the company to issue a $3.5 million purchase order for the fabrication of the conveyor system to Rapat Corp. of Minnesota, and for procurement packages to be prepared for thickeners, inching drive, and third zinc cleaner cell replacement.

Work has started now to complete the power distribution upgrades at the Russell portal to provide 1.85 MW to the underground mine, and remove the need for diesel power in the underground environment. This will be followed by the completion of a feeder between the Bunker Hill and Big Creek substations to allow for shifting of load between those key facilities.

To ensure adequate support to the processing operations at the main Kellogg site, the next phase will see the upgrade of the distribution system through the installation of 5.0 MW by August 2024, an additional 1.2 MW by August 2025 and a further 2.0 MW by August 2027. These upgrades will then be further enhanced with investments in load management and the construction of a larger transformer at the Bunker Hill site to ensure a dedicated feeder position to serve the mine.

The power provider, Avista Utilities, and Bunker Hill are working together to deliver low-cost, hydro-electric/green grid power for as low as $0.047/KWh, thereby setting the conditions for the replacement of all diesel-powered equipment with modern electrical machinery at some time in the future.