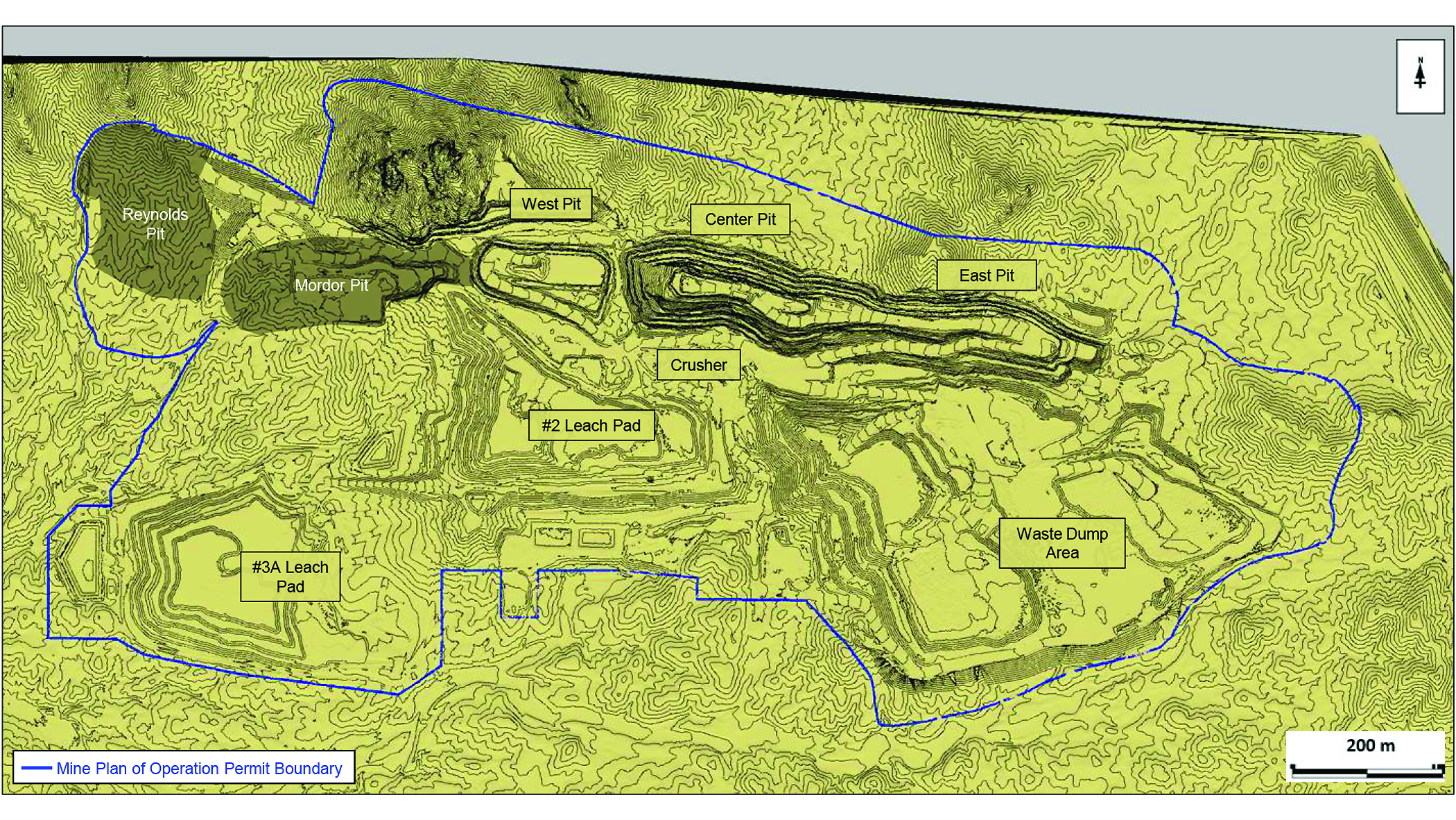

An aerial view of the Moss mine looking east shows the West and East Pits and the crushing installation in the center. (Photo: Elevation Gold)

Efforts to develop a workforce culture while chasing gold veins pays dividends

By Steve Fiscor, Editor-in-Chief

Elevation Gold Mining Corp. operates the Moss mine in Mohave County, Arizona. The company produced 8,380 ounces (oz) of gold and 53,911 oz of silver in Q3 2023, and 7,989 ounces (oz) of gold and 60,706 oz of silver in Q4 2023. Those quarterly figures, which were an improvement over the previous two quarters, only tell half the story.

The Moss mine encountered higher grade ore which fragmented better, leading to record crusher throughput, and some much-needed operational stability. The mine is currently extracting ore from the West Pit and Mordor areas, and they recently completed the 3B Leach Pad, on time and under budget. Through Q3, 2023, cash costs are down $262/oz for the year versus similar periods last year, reflecting great work by the team at Moss mine.

Mining plans are not the only transitions at the Moss mine. New approaches to management are leading to a cultural shift in the workplace. “We have been working hard to improve the workplace culture and safety at the same time,” said Elevation Gold CEO Tim Swendseid. “We have improved our training programs, and our safety reporting system. We are now offering competitive compensation and have created a more inclusive work environment.” These changes have led to a more loyal workforce that’s operating more safely.

After encountering hard ore in the East Pit, mining operations have transitioned to the Mordor Pit west of the West Pit. (Source: Elevation Gold)

Moss Mine Transitions to the West

Mining in the East Pit is now complete and most of the mining activity is focused on the Mordor area and the West Pit. “We fired the last blast in the East Pit in early December,” Swendseid said. “There is some additional drilling that we hope to do that would allow us to deepen the East Pit. That’s part of a longer-term plan that would require the relocation of the crusher to access a rich zone where the Ruth vein intersects the Moss vein. We’re hoping that will be included in the plan for seven to 12 years out, but we need to perform some additional drilling to confirm that ore first.”

The Moss mine is already stacking ore on the new 3B Leach Pad, which was completed in early November. Designed by Newfield’s and constructed by Ledcor, it’s a 1 million ft2 pad and it will add 2.5 years of capacity, Swendseid explained. “It will give us production capacity through the end of 2025,” he said. “We like to build them in 2-year increments. We’re already working on the design for the next pad and plan to start construction in late 2025.” Building leach pads is a large capital expenditure, and the company tries to pace itself to spread out those capital costs as part of its cash flow management.

Meanwhile, exploration drilling continues in the Reynolds pit. “We had some very interesting drill results in the Reynolds pit recently,” Swendseid said. “One of the holes turned out to be the most exciting hole ever drilled at the Moss mine. Hole AR23-663R intersected 225.6 meters of mineralization grading 0.56 grams per metric ton (g/mt) of gold and 2.77 g/mt of silver. The grade was well above our operating cutoff grade of 0.31 g/mt. It looks like we have found an area with the potential to dramatically improve economics in the western side of the pit.”

The new ore zone is within Elevation Gold’s permitted area for mining and leaching. “We performed a small drilling campaign a couple of months ago and we are currently in the middle of another small campaign trying to connect the dots,” Swendseid said. “From the assays that have been reported so far, it looks like we have hit the same ore zone in three drilling fences.”

The miners knew the Moss vein was there and they suspected there could be more gold in the area. “The mine’s exploration geologist at the time decided to drill a hole toward the south, and low and behold, he hit this really decent ore zone,” Swendseid said. “The East Pit is currently our best ore zone as it has a much better grade than the West Pit, and this new mineralized zone may be as good or better than the East Pit.”

The 3B Leach Pad was completed on time and under budget. (Photo: Elevation Gold)

Production in the West Pit is currently being supplemented with ore from the Mordor area, which is a little bit west of the West Pit. “The Mordor area is an area that was also under explored,” Swendseid said. “About five years ago, someone put some percussion holes into it, but it was never drilled well enough to be placed into the orebody model. After some additional drilling, we decided to move the production blasthole drills there and started mining the Mordor area. We have since hit some very good ore or what we call a ‘very positive reconciliation’ to what the orebody model predicted.”

The geology in the West Pit had become very hard to the point where it was affecting fragmentation and crushing negatively. The rock in the Mordor area is completely different. It’s easier to blast and crush and has a better grade.

Today, most of the mining at the Moss mine is concentrated in the Mordor area. “We are working off of a mine plan for an area that remains under-drilled, and we can’t get drill holes in it fast enough to fully understand it,” Swendseid said.

Improving the Workplace Culture

Elevation Gold has invested considerable effort in improving the workplace culture at the Moss mine. The company brought Justine De Boom on board as vice president of human resources. In the past, the company had a punitive attitude toward employees, Swendseid explained. “If they had a safety issue or did something that they ought not do, maybe even because of improper training at the mine itself, they were terminated and the mine suffered from an extreme amount of turnover,” he said.

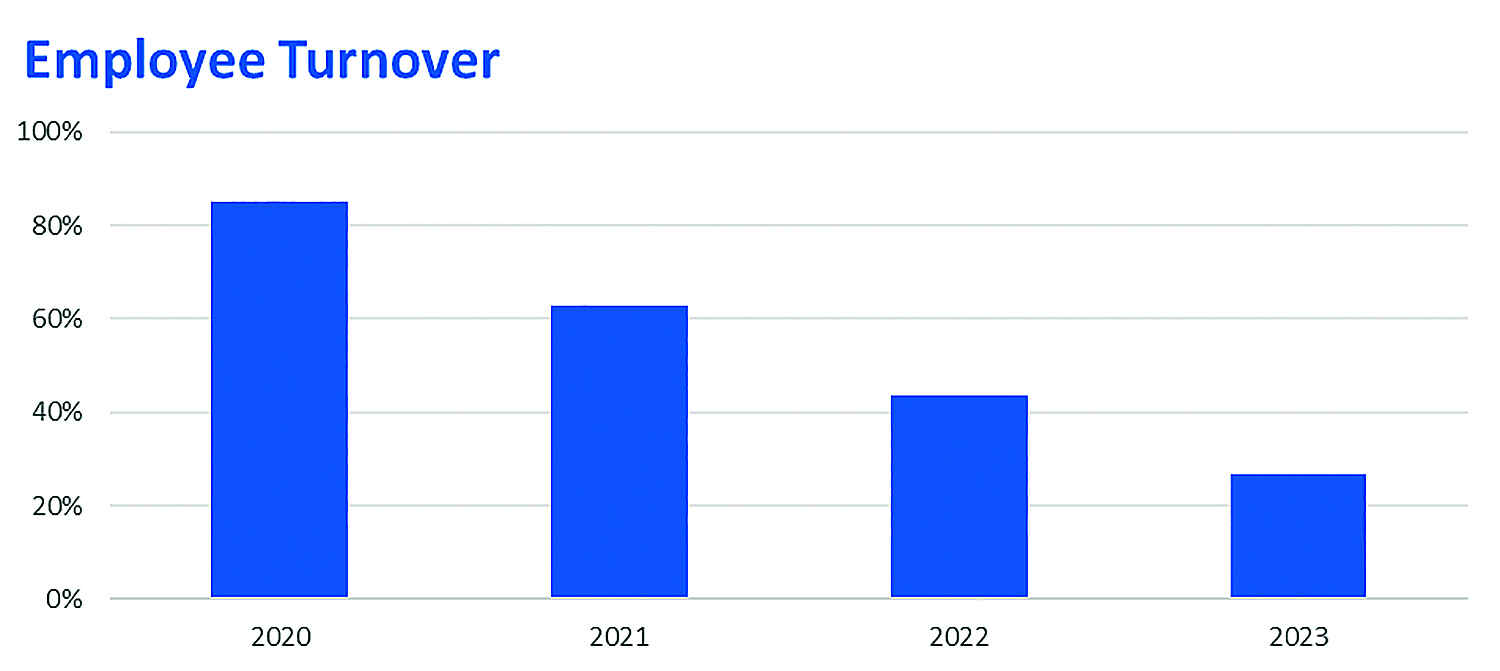

De Boom identified the issues and has focused her efforts on building an inclusive workplace culture that engages employees. One of the primary objectives was to improve safety by offering more training and allowing people to report safety incidents, especially near misses. “We needed to learn from them,” Swendseid said. “The entire cultural improvement effort has resulted in a workforce that’s much more loyal and our retention rates have improved dramatically. Our turnover rate is still high, but it is way better than what it was.”

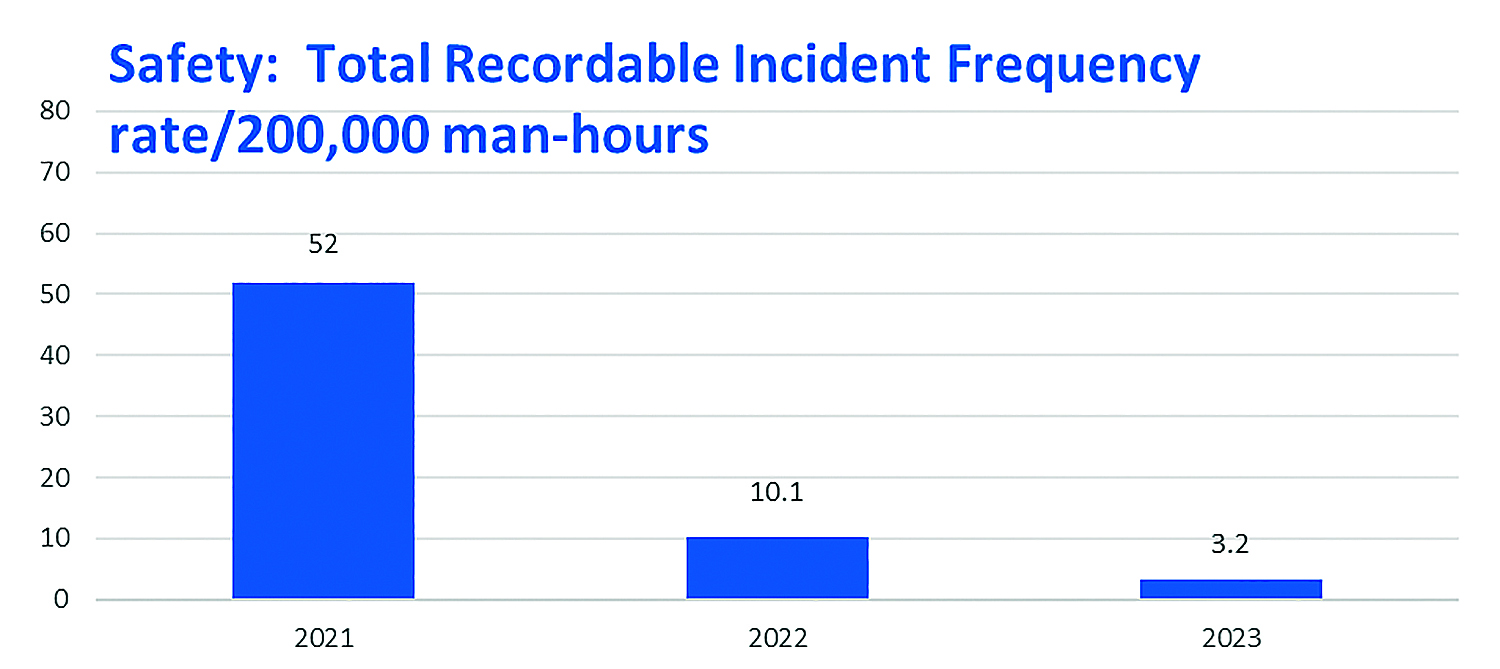

The results can also be seen in the mine’s total recordable incident frequency rate for 200,000 man-hours. “We have brought that statistic way down and we are now confident that we are reporting everything properly,” Swendseid said. “At the same time, the number of near-miss incidents reported has increased dramatically. We applaud people who turn in a near miss incident through our Good Catch Program.”

The program identifies the actions or inaction that led to the near miss and asks how it can be prevented in the future. It also rewards employees that participate in the program. “We also now offer production bonuses, and our workforce has become a more inclusive group,” Swendseid said.

Elevation Gold also brought Jim Fowler on board as the general manager of the Moss mine. “He has worked in Arizona for the majority of his career, and he is a solid coach and mentor with a ton of operating experience,” Swendseid said.

The continued focus on safety and employee retention has created a more stable workforce, which has led to consistent operations and will allow us to drive costs down in the future, Swendseid explained. “With our low-grade ore, keeping costs at a minimum is a company-wide requirement,” he said.

The Moss mine employs 200 including contractors, and the main mining contractor is Ledcor. “The demographics that we pull from for the workforce come from the Bullhead City, Arizona, and Laughlin, Nevada area,” Swendseid said. “The base of employment in that region is hospitality related, people who work in the casinos, hotels, and restaurants. So, they are not mining people per se. We train them and teach them about mining and operating safely and give them the opportunity to secure a long-term career that pays better than the hospitality industry.”

Swendseid said it’s rewarding to see the workforce stabilize. “When I arrived a couple of years ago, we were coming out of COVID-19 and it was hard to keep people at any of the positions,” Swendseid said. “People would not show up for interviews and Starbucks was paying more than we were. Today, the tables have turned.”

Looking toward the future, Swendseid said his vision is to continue drilling these geologic structures that run from the east to the west and identify enough gold to keep the Moss mine in business for the next 10 to 15 years. They also need to get through a permitting phase to expand their operation. Elevation Gold still has 165 km2 of exploration area at the Moss mine and they are still finding targets adjacent to the active mining areas.

Elevation’s efforts to improve workplace culture has resulted in a steady decrease in employee turnover. (Source: Elevation Gold)

The Good Catch Program

Staff turnover and safety in the workplace are interlinked. Three years ago, the Moss mine had a poor safety record, and it was experiencing high staff turnover. “In an effort to focus on positive behavioral safety programs, we developed the Good Catch Program,” said Justine De Boom, vice president of human resources for Elevation Gold. “Before something becomes a near miss, before it becomes an incident, we get out there and positively identify this issue that has the potential to injure somebody or create a hazard in the workplace. And, we have built that into the production values of the mine site itself.

The punitive mentality toward safety was working against the Moss mine. “As quickly as we could hire people, they were leaving because of this punitive mindset,” De Boom said. “If somebody did something wrong, they were terminated. We needed to develop a culture and we began to change the way we do business. Today, we are hiring people from the local communities, training them and molding them into miners, and it has paid off.

De Boom worked with Moss’s managers to develop training plans. They also implemented regular performance reviews. “I personally attend every performance review,” De Boom said. “It’s important for me to connect with the employees whilst we get some great feedback.”

With a new program in place, the Moss mine’s total recordable incidence frequency rate has declined dramatically. (Source: Elevation Gold)

The mine now surveys its employees and asks their opinions. “Before we make a change in the workplace, we send out a survey,” De Boom said. “It’s important for employees to be part of the decision-making process. Their opinions mean something. We do a lot of consultative work with our employees. It’s human nature for people to be critical of any workplace. We’re not perfect, but I think when you make them part of that process, they feel that they are valued as an employee.”

De Boom added “we also focus on connecting with all employees by conducting quarterly communication meetings with management to provide an overview of the mine’s performance and listen to employee feedback about how we can better do business. Additionally, a key performance indicator for the Executive Management team is to attend the department line out meetings and interact daily with the safety management of the mine site. Communication has been the key to their success.”