Northern Star Resources’ board approved the development of the A$1.5 billion ($1 billion) KCGM Mill Expansion Project, to extend the life of the Super Pit. “Today is exciting for Northern Star and a historic new chapter for this world-class asset,” Northern Star Managing Director Stuart Tonkin said. “The board’s decision to approve the KCGM mill expansion and optimization represents the next stage to revitalize our largest asset as well as the surrounding district for decades to come.”

Northern Star Resources’ board approved the development of the A$1.5 billion ($1 billion) KCGM Mill Expansion Project, to extend the life of the Super Pit. “Today is exciting for Northern Star and a historic new chapter for this world-class asset,” Northern Star Managing Director Stuart Tonkin said. “The board’s decision to approve the KCGM mill expansion and optimization represents the next stage to revitalize our largest asset as well as the surrounding district for decades to come.”

“Our confidence in the economics of KCGM to remain a long-life, low-cost gold mine has been further reinforced through the feasibility study phase. Expanding the processing capacity of KCGM will strengthen Northern Star’s portfolio, materially increase our free cash flow generation and progress our long-term strategy to be within the 2nd quartile of the global cost curve.

Located in Kalgoorlie, Western Australia, the KCGM Operation (aka Super Pit) is one of the world’s largest and most significant gold mines with a mineral resource of 28.3 million oz and an ore reserve of 12.2 million oz. The growth optionality that comes with owning an asset as large as KCGM is significant and arguably unmatched across Australia.”

Northern Star acquired 50% of KCGM in 2020 and assumed 100% control of KCGM as a result of the merger with Saracen Mineral Holdings Ltd.

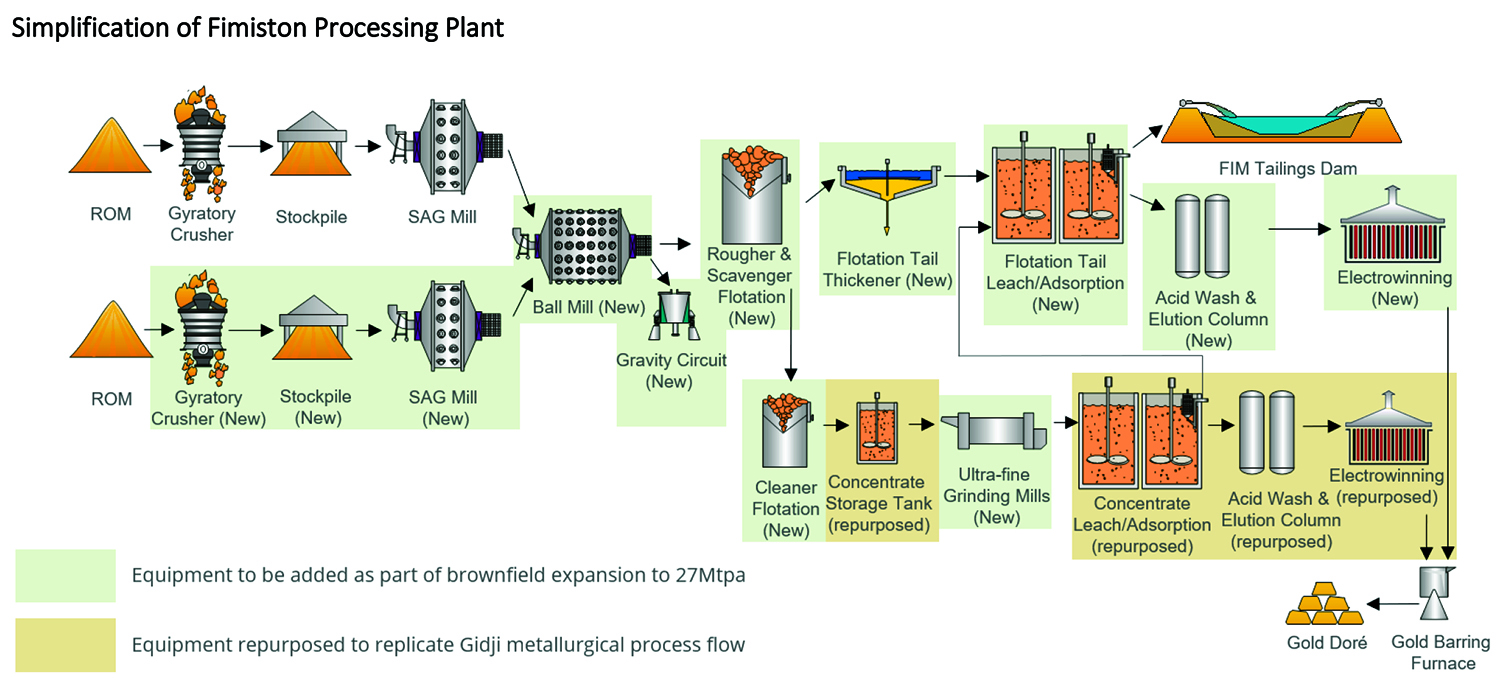

The capacity of KCGM’s processing circuit, centered on the Fimiston processing plant, will increase from 13 million metric tons per year (mt/y) to 27 million mt/y. Leveraging off the known metallurgical performance of the operation significantly lowers the project’s technical risk. Proven processes will

be retained (~20% of the existing

plant) and the largest process equipment will be sourced from leading tier-1 manufacturers.

Core design principles were to deliver a facility that has maintainability, operability and maximized plant availability. As such, the new plant will have a high level of process automation, control and condition monitoring. Increasing the plant throughput combined with simplifying the existing flow sheet should lead to an increase in gold production capacity with improved gold recovery rates (~1%). It will also provide a sustainable reduction in unit rate processing costs with large-scale efficiencies and reduced reagent consumption rates. The company also expects a reduction in fixed operating cost per ton of ore processed.

Northern Star Resources has placed a $222 million order with FLSmidth for a wide range of mineral processing technologies for the expansion project, including a SAG mill, a ball mill, a primary crusher, pebble crushers, flotation cells and a pre-leach thickener. In addition to these technologies, the order also includes spare and wear parts. The 20-megawatt grinding mills will be the highest power, gear-driven mills in the world, and the ball mill will be the first gear-driven 28-ft dia ball mill.