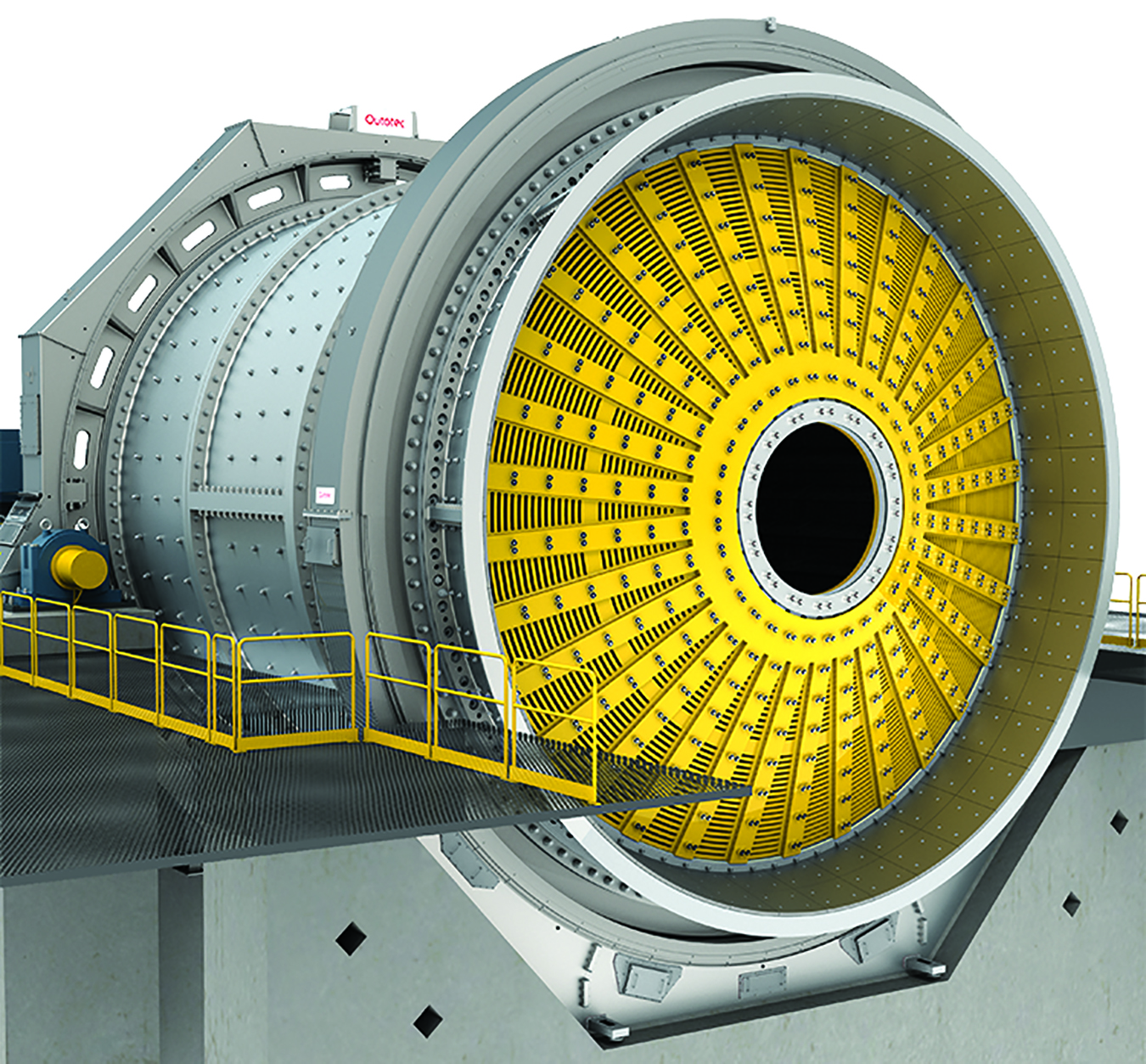

Outotec launched a grinding mill with an open-ended discharge, the OED Mill. This large high-capacity grinding mills offer reductions in both CAPEX and OPEX.

Outotec launched a grinding mill with an open-ended discharge, the OED Mill. This large high-capacity grinding mills offer reductions in both CAPEX and OPEX.

Instead of using pulp lifters, the OED Mill discharges material directly through the grates. It uses a novel grate-supporting spider to maximize slurry transport and minimize slurry pooling, the company reported.

Key benefits offered include highest possible discharge capacity, maximized slurry transport and impact energy with lowest possible slurry pool level, and optimized serviceability and availability.

The mill enables circuit designs with reduced equipment requirements, lowering CAPEX. Reductions in OPEX stem from a reduced need for grinding media.

Separately, Outotec released the Mill Equipment Transporter, a specialized mobile unit for the safe and reliable transportation of feed chutes and more. It has independently driven wheels and independently controlled rear steering, enabling it to turn on the spot. The pivoting rear axle ensures that all four wheels are always in contact with the deck, while large rubber tires optimize load distribution.

Separately, Outotec released the Mill Equipment Transporter, a specialized mobile unit for the safe and reliable transportation of feed chutes and more. It has independently driven wheels and independently controlled rear steering, enabling it to turn on the spot. The pivoting rear axle ensures that all four wheels are always in contact with the deck, while large rubber tires optimize load distribution.

It has a built-in safety system and a multi-language display. Benefits include improved safety when moving large loads, real-time feedback for the operator, and compatibility with smaller deck designs.

Outotec also released the Tube Mill Reline Machine, a compact relining solution for smaller SAG and ball mills. Tube design minimizes the required mill opening size while maximizing the usable area for liner delivery. It provides fixed three-axis hydraulic crane support.

Benefits include the safe relining of smaller SAG and ball mills unsuitable for traditional reline machines, easier navigation of small mill decks, user-friendly operation, and lower capital cost and simplified maintenance.

www.outotec.com