FLSmidth will provide engineering, supply of equipment and service to the Sales de Jujuy Olaroz lithium facility in Argentina, formalizing a relationship that commenced in early 2020. The order, valued at around DKK200 million (US$31.9 million), has been booked in the third quarter.

FLSmidth will provide engineering, supply of equipment and service to the Sales de Jujuy Olaroz lithium facility in Argentina, formalizing a relationship that commenced in early 2020. The order, valued at around DKK200 million (US$31.9 million), has been booked in the third quarter.

FLSmidth will also provide site services including installation supervision, commissioning and training. The new plant will increase output at the site, maintaining its position as a major lithium producer in Argentina. This new lithium extraction facility will provide technical-grade lithium carbonate, which, with further purification, will be used to produce battery cathodes for the growing electric vehicle market. Toyota Tsusho Corp. owns 25% of the facility.

“Following our involvement in extensive process design at Olaroz, we are very excited Sales de Jujuy has entrusted FLSmidth to supply technologies for their new, world-class lithium extraction plant in Argentina,” FLSmidth Mining Mikko Keto said. “This order, in addition to the other lithium extraction orders announced earlier in 2021, confirms FLSmidth’s leading position as the technology provider of choice for all types of lithium deposits globally. It’s also satisfying to partner with a company that shares FLSmidth’s commitment to environmentally sound lithium production – a great match for our MissionZero ambitions.”

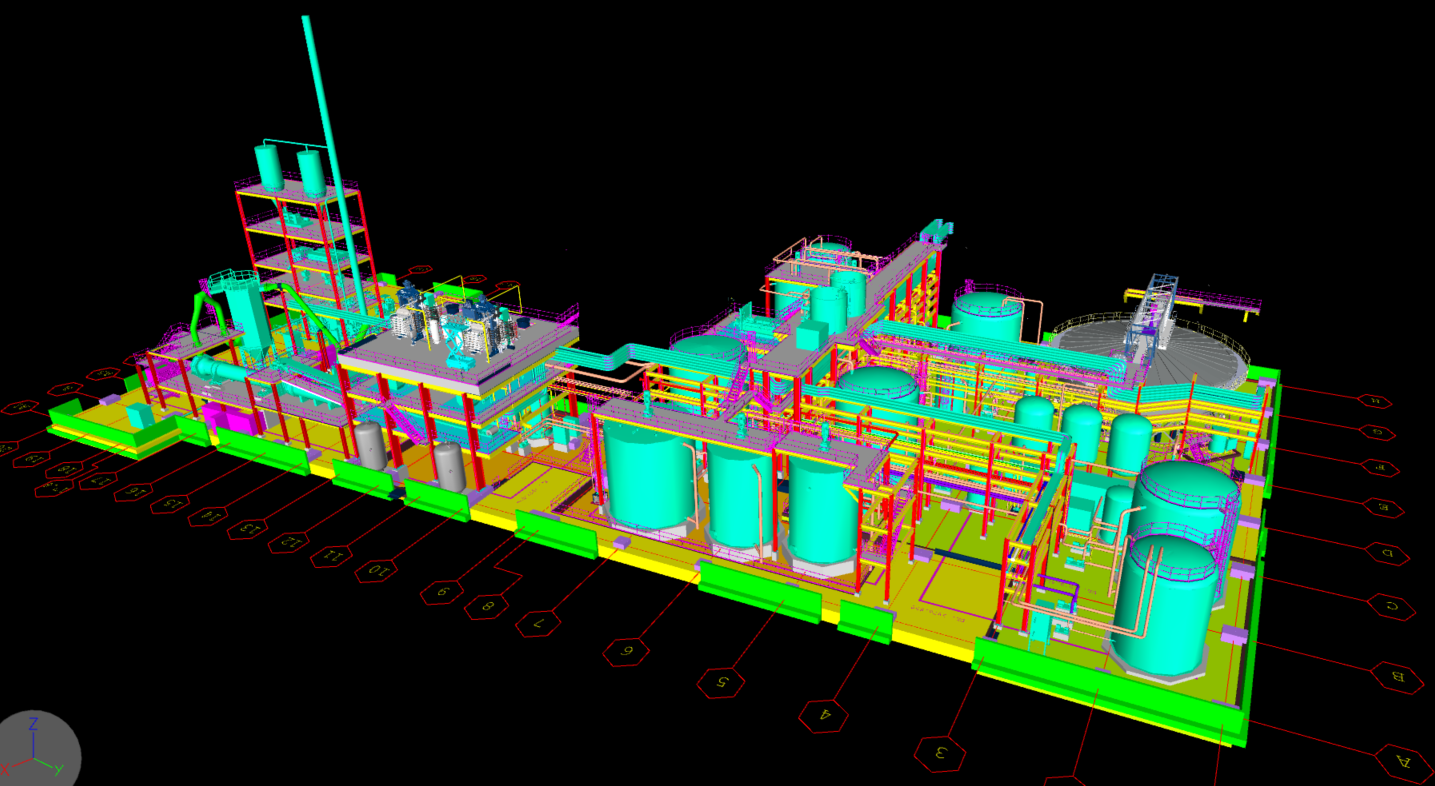

The technology provided by FLSmidth includes a clarifier, Pneumapress filters, Shriver filter press, OTG polishing filters and a pyromet dryer package. The technology package also includes other important equipment such as the reactors, ion exchange, pneumatic transport system and a bagging package. Equipment delivery will begin shortly and the contract will be complete by end of 2022, with the final trainings.

“FLSmidth is a world leader in environmentally sound lithium processing technologies,” said Fernando de la Calle, engineering project director. “This aligns with Sales de Jujuy’s ambition to not only produce materials necessary for electric vehicles and renewable energy infrastructure, but to do so in an efficient and environmentally responsible manner through lowered emissions and significantly reduced water usage.”

The FLSmidth state-of-the-art equipment will deliver high availability and high productivity and mean low energy consumption and resource-efficient operations. The new plant is expected to produce 25,000 metric tons per year (mt/y) of technical-grade lithium carbonate.