ABB is launching a new digital suite of applications for hoist monitoring and optimization, rebranded as ABB Ability Smart Hoisting. “Through the integration of predictive maintenance and advanced monitoring, the evolved ABB Ability Smart Hoisting solution marks a pivotal milestone in redefining the performance benchmarks for mine hoists,” said Charles Bennett, global service manager, hoisting at ABB. “This transformative solution addresses industry challenges comprehensively.”

ABB is launching a new digital suite of applications for hoist monitoring and optimization, rebranded as ABB Ability Smart Hoisting. “Through the integration of predictive maintenance and advanced monitoring, the evolved ABB Ability Smart Hoisting solution marks a pivotal milestone in redefining the performance benchmarks for mine hoists,” said Charles Bennett, global service manager, hoisting at ABB. “This transformative solution addresses industry challenges comprehensively.”

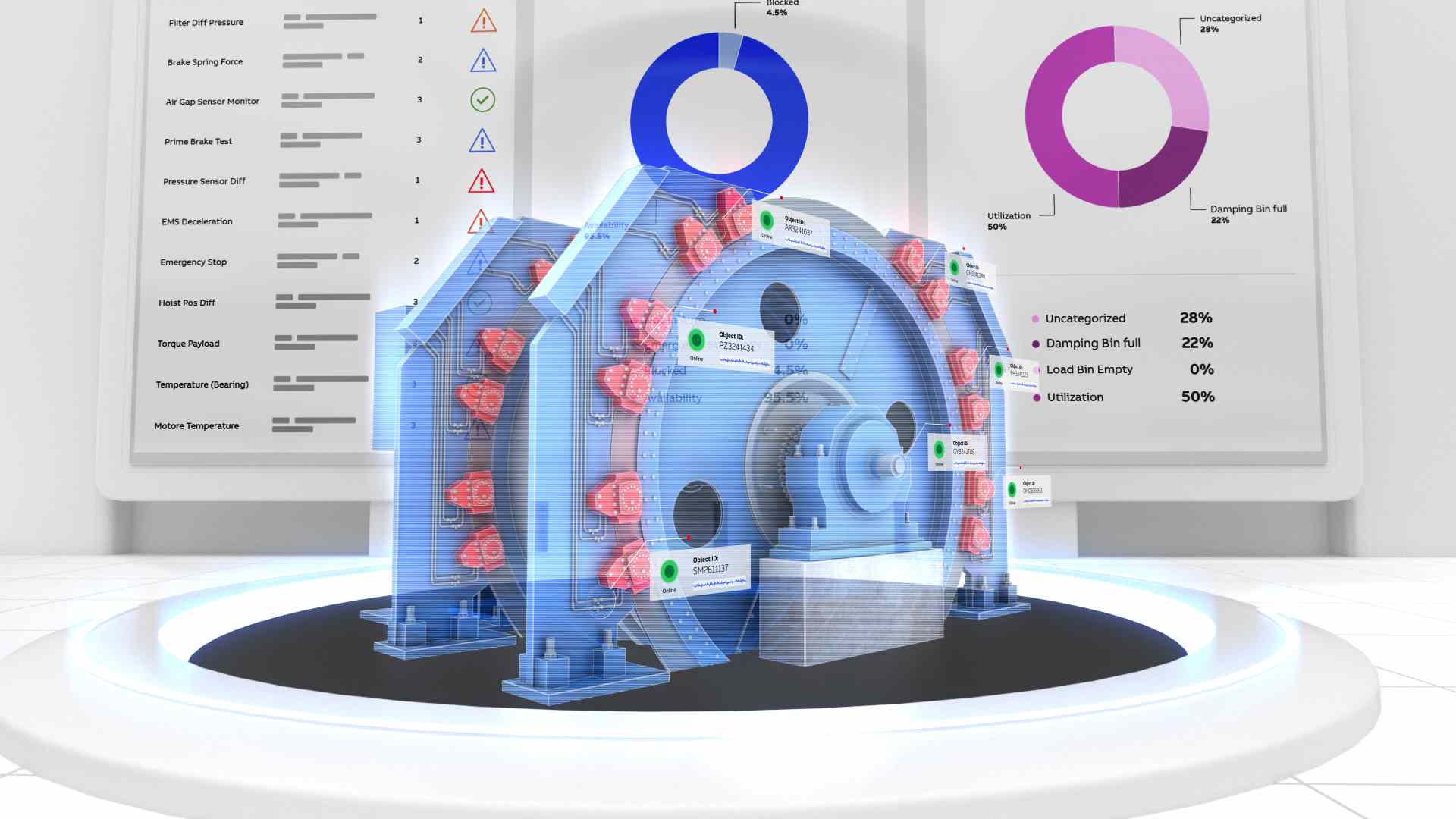

With new features such as drive system monitoring and new key performance indicators (KPIs), the system could open the door to an entirely new level of mine hoist optimization. Traditional predictive maintenance approaches rely on manual data collection and analysis over a short period of time. Intermittent issues can stay hidden or only be identified later, giving engineers little time to program interventions. Manual data collection and analysis is also a time-consuming process.

ABB expects the Smart Hoisting platform to significantly improve the uptime, availability, reliability, performance and productivity of hoists. By incorporating advanced monitoring features, the system provides actionable information on critical KPIs, ensuring better decision-making and optimization of hoisting operations. The automatic collection, monitoring and analysis of data will enable mining companies to increase production performance, identify potential functional safety hazards and optimize maintenance scheduling. The combination of innovative features and improved cyber security could make this a valuable tool for the underground mining industry.