Dassault Systèmes, parent company of mining software solutions provider Geovia (formerly Gemcom), recently issued a congratulatory press release recognizing its customer, Dundee Precious Metals, for receiving the 2013 Ingenious Award presented by the Information Technology Association of Canada (ITAC). The awards program highlights enterprises that demonstrate measurable evidence of productivity improvement, efficiency gains, revenue growth, overall business transformation or other organizational outcomes through the use of technology. Dundee Precious is a Toronto, Canada-based mining company that garnered ITAC’s attention by aggressively increasing production, while at the same time reducing costs, at its Chelopech mining operation in Bulgaria.

|

| A major data and communications upgrade had a strong impact on performance at Dundee Precious Metals’ Chelopech underground mine, enabling the company to increase production by 53%. At the same time, it reduced production costs 30% per metric ton and cut its IT costs by $1.5 million annually. (Photo courtesy of Dundee Precious Metals) |

Geovia CEO Rick Moignard said, “Dundee’s ‘Taking the Lid Off’ initiative at Chelopech put it at the forefront in leading change in the mining industry to utilize technology to drive efficiency and productivity gains. The mine has been able to go from producing 1 million to 2 million tons a year purely as a result of operational improvements, without the addition of any new mobile mining equipment.”

As explained in ITAC’s description of the award winners’ accomplishments, the Chelopech underground mine was mired in the past, technologically: modern communications systems played a small role in its processes. Mine workers were still submitting paper reports at the end of each shift, while the next shift wandered around trying to locate equipment and vehicles needed to carry on mining.

Mark Gelsomini, Dundee’s corporate director of IT, was given the responsibility of bringing the Chelopech mine into the 21st century. The first step was to replace the mine’s industry-standard RF voice network with a new Wi-Fi network from Cisco.

Geovia’s InSite mine production management and GEMS geology and mine planning software applications formed key components of the new technological backbone at the Chelopech mine. By integrating with other vendors’ systems, mining equipment, and the Wi-Fi network, the mine is now able to visualize its operations in real time.

Paper reports have been replaced with a 3-D tracking system, originally designed for the health care industry, to acquire real-time visibility into the entire underground operation, including the movement of ore along the conveyor belt and the current location of individual miners. The system can monitor the status of each piece of equipment and schedule preventive maintenance before an outage occurs.

The results of the modernization had a major impact on Dundee’s bottom line, enabling the company to increase production at the Chelopech mine by 53%. At the same time, the company reduced production costs 30% per metric ton, while simultaneously lowering IT costs by $1.5 million annually.

While Geovia is justifiably pleased about the role its product management software played in the success of the mine upgrade, it hasn’t lost focus on the fact that any mine’s success rests firmly on the quality of its design and planning efforts. In support of those vital operational components, the company recently released updates to GEMS and Surpac that bolster their mine design and planning capabilities considerably.

Surpac 6.6, according to Geovia, introduces the first mining software solution with features specifically suited for the design of stope shapes. In- cluding the interactive Stope Designer and Stope Slicer tools, the new Stope Design Tools module provides underground engineers and designers with a new way to design stopes efficiently.

Geovia claims the new Stope Design Tools module offers a simple and fast stope design process to improve operational results and productivity by maximizing ore recovery while minimizing costs. As part of the module, the new interactive Stope Designer tool steps through planes to delineate practical stope boundaries—ultimately creating a designed solid, which the Stope Slicer tool divides into practical mining shapes using planes and elevations to produce stope, pillar and crown pillar solids quickly.

Eliminating the need for highly complex and inefficient macro-based solutions, the interactive Stope Designer tool allows underground engineers to create practical mining shapes quickly. By stepping back and forth through a series of planes to digitize a desired outline on each plane, any number of reference solids, surfaces or block models can be used to guide the design process. The polygons on each plane can be quickly evaluated using the block model, which allows for rapid refinement of the designed shape. Once the polygons on all planes have been designed, the volume, mass and grade of all material types are calculated and assigned to the designed solid for reporting and analysis.

Stope Slicer enables underground mine designers to produce practical mining shapes quickly by dividing any solid into smaller solids that represent the stoping units to be mined. By allowing multiple scenarios to be considered, this tool allows the optimal de- sign to be identified for use in downstream planning and scheduling activities to satisfy mining objectives. Once produced, resultant solids are organized, named and tinted to distinguish stopes from pillars and crown pillars, which can then be used in Geovia’s MineSched long-term and short-term scheduling product.

|

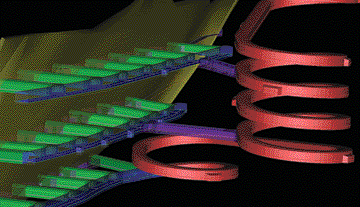

| Geovia says the introduction of a new ramp design tool in the GEMS Tunnel Design Module simplifies the current ramp design process by eliminating many small repetitive tasks. |

In addition, the company released GEMS 6.6, which introduces a range of new tools designed specifically to help underground mine planners. Geovia noted that the introduction of a new ramp design tool in the Tunnels Module improves the current ramp design process, eliminating many small repetitive tasks by rolling them into one step. Users will also benefit from the ability to make changes throughout the design process, eliminating the need to start again when changes are necessary.

With the introduction of the ramp design tool in the Tunnels Module, GEMS 6.6 now offers a set of dedicated tools that roll multiple repetitive tasks into one step. With the ramp design tool users can:

- Specify entry and exit points of ramps, both together or individually, avoiding manual calculation of positions.

- Save time by selecting the most com- monly used ramp styles from a range of preconfigured templates.

- Rapidly evaluate and schedule re- source extraction, enabling quicker overall mine design.

- Complete mine development design faster when the resource model changes as a result of volatility in commodity prices or additional exploratory work.

GEMS 6.6’s line regrade feature, available as part of GEMS core, allows specified grade parameters to be preserved when moving lines or segments to new positions, eliminating the need to recreate them from scratch. The process of checking coordinates and manual calculation of gradients is also eliminated, enabling even more time savings. Regrade allows for rapid redesign or design modifications when changes in level height are necessary without the need to start from scratch.

The new gradient smoothing feature removes the need to manually digitize incrementally changing segments. It provides the ability to merge intersections with existing tunnel centerline so that line segments transition smoothly, as well as smooth the gradient of a tunnel centerline based on equipment tolerances.

Additional enhancements to GEMS include licensing changes to enable multiple dongle use on the same machine; new view options (XY, YZ, XZ buttons), which allow the user to quickly navigate to axis-oriented views; a new file export format for solids that utilizes the extended character name introduced in GEMS 6.5; and a number of small defect corrections.