Sandvik Mining and Rock Technology launched the DT1132i three-boom, electrohydraulic jumbo for tunneling and cavern excavation. The drill is described as suitable for fast face drilling or mechanized long-hole drilling and bolting.

All Sandvik DTi tunneling jumbos have been developed with a special modular design that makes them highly flexible and versatile, the company reported. The computer-controlled DT1132i possesses both operator-controlled boom positioning and full-face automatic drilling functions. It uses Sandvik’s RD535 rock drill and advanced drill string guides.

Drill plan visualization and rig navigation come standard. Other control automation upgrades are available.

The DT1132i possesses a powerful transmission system with a (Stage 5) Cummins B6.7, 168-kilowatt (kW) diesel engine that can be operated up to 5,000 meters (m) above sea level without any modifications, the company reported. Other features include automated tools that enable up to 40% less exhaust particles, a 20% higher penetration rate, and 25% more side coverage.

The drill has a 3-m telescopic TB160i boom that uses a fully proportional boom control for accurate and fast manual boom handling. It can be upgraded to full automation.

The vibration-dampened cabin is ergonomic and offers excellent all-round visibility, Sandvik reported. Comprehensive diagnostics information is integrated into one display.

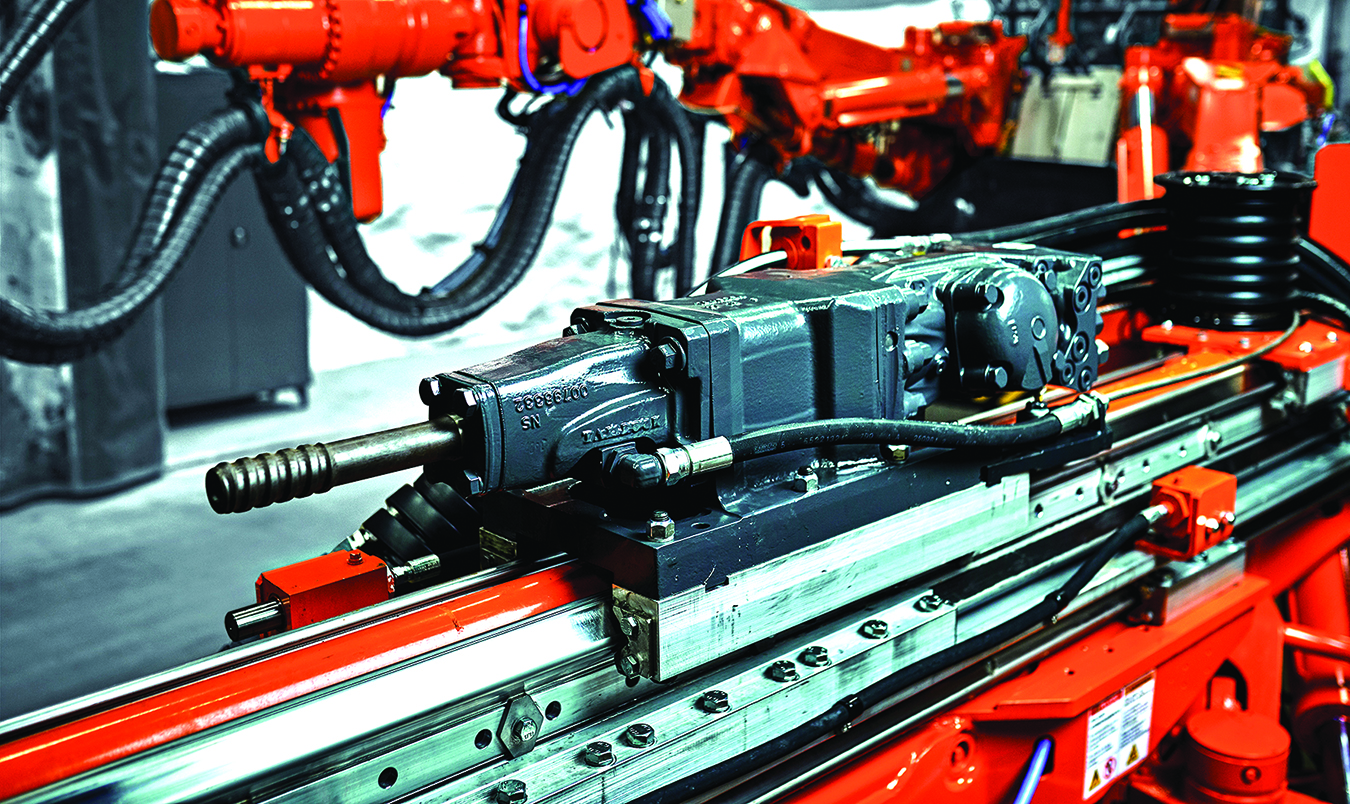

Paired with the high-frequency rock drill RD535, the rig provides users with a heavy-duty solution for underground drilling, Sandvik reported.

Separately, Sandvik reported the new RDX5 rock drill will replace the HLX5, reputed to be the world’s most reliable rock drill. The RDX5 is completely interchangeable with the HLX5.

Separately, Sandvik reported the new RDX5 rock drill will replace the HLX5, reputed to be the world’s most reliable rock drill. The RDX5 is completely interchangeable with the HLX5.

The RDX5 has a significantly increased minimum service interval compared to the HLX5. Designed similarly to the HLX5, the RDX5 has a minimal number of moving parts and pressurized seams, the company reported.

Several components, to include the flushing hear and the body cylinder, were modified for improved durability. The percussion package and piston design enable improved efficiency.

The RDX5 is available through local Sandvik suppliers.

Sandvik also announced iSURE 8.0, underground rock excavation software. iSURE is a purpose-developed excavation process-control tool for providing instrumented face-drilling rigs with the necessary information for optimized drilling and blasting, the company reported.

The software provides a set of drill and blast plan templates for editing and feedback functions. It captures percussion rate, and tracks drilled meters and net penetration, which gives needed feedback and allows for critical adjustments, Sandvik reported. These capabilities and more can be used to improve the work cycle and blast excavation process.

www.rocktechnology.sandvik