In round figures, 580,000 visitors from 200 countries arrived in Munich in April for bauma, the world’s largest equipment fair. That’s an increase of more than 9%. After Germany, the top 10 countries of origin among the visitors were Austria, Switzerland, Italy, France, the Netherlands, U.K., Sweden, the Russian Federation, Poland and the Czech Republic. A total of 3,423 exhibitors—1,263 from Germany and 2,160 from abroad—from 58 countries presented their products, developments and innovations on a record 605,000 m2 of exhibition space. Exhibitors from outside Germany accounted for 63% of the total—higher than ever before.

“The response from the participants this year was amazing,” said Klaus Dittrich, chairman and CEO of Messe München, bauma’s organizers. “Many exhibitors are talking about a record level of demand at bauma 2016. And that is an extremely positive sign in this current uncertain climate.”

Stefan Heissler, a member of the Board of Directors of Liebherr-International AG, confirmed, “bauma 2016 was a tremendous success for Liebherr. We received many orders from a wide variety of different markets. In some segments our expectations were even exceeded.”

The mining equipment at bauma is a focal point for the crowd.

While bauma is mostly a construction event, activity in the mining hall C2 was brisk. Erwin Schneller, managing director for SBM Minerals, reported, “bauma is very international. We had visitors from Chile to Canada, from China to Russia, from Africa to Norway. My personal highlight was that we signed up some unexpected sales at the show.”

The next bauma takes place from April 8 to 14, 2019, in Munich.

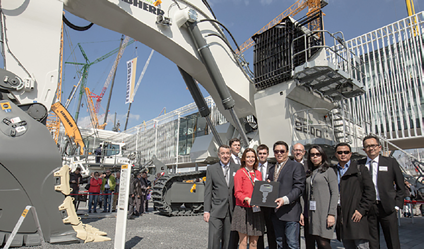

Liebherr Celebrates Successful R 9200 Launch

Although Liebherr only unveiled the R 9200 mining excavator to the public for the first time at bauma 2016, the family-owned company has already sold 10 of the new 200-ton machines. “The initial field test and the customer feedback from machines in operation thus far confirmed excellent productivity with lower fuel consumption,” said Dr. Jörg Lukowski, managing director of sales at Liebherr-Mining Equipment Colmar SAS. “And, if you have a walk around on the machine, you will note how proper and tidy the machine is designed. These elements paired together have created a high interest in the new R 9200 machine, of both existing and new customers.”

The Indonesian company PT Darma Henwa ordered three machines alone, which were symbolically handed over by Sophie Albrecht to CEO Wachjudi Martono at the Liebherr exhibition stand.

“The Liebherr team in Indonesia is always very involved and provides us with excellent support. This support characterizes our relationship with the Liebherr Group very well,” stated Wachjudi Martono, praising the relationship between the two companies. PT Darma Henwa’s fleet of machines already includes two R 9100s, two R 9350s and one R 984 C. The three R 9200 mining excavators will be used in coal mining applications.

“We are all delighted with this package order,” Lukowski said. “It confirms the trust of PT Darma Henwa in our products and services and affirms the development of a strong relation between our companies on a local and corporate level.”

In related news, Liebherr has decided to retire production of its 675-hp R 984 excavator, which was launched in 1986. With more than 1,100 units sold worldwide, the R 984 mining excavator earned a solid reputation as one of the most flexible digging and loading tools in the 120-ton class.

Sophie Albrecht hands over the symbolic R 9200 key to Wachjudi Martono, PT Darma Henwa CEO, at bauma 2016.

Tsurumi Brings Big Pumps

Pump manufacturer, Tsurumi, stood out at bauma with two superlatives: the new LH4110W and KRSU822. The LH is now listed as its strongest submersible pump with a maximum head of 216 m. Tsurumi’s new flagship was a prominent sight with a dry weight of 1.3 metric tons and a 1.8-m construction height. With a 110-kW motor, it is used in applications where large distances have to be covered. The LH can handle sediment with up to 8-mm particle diameter.

The new KRSU822 turns up the power even more if a really “thick liquid” needs to be pumped: after all, the clear passage of 56 mm makes it the medium of choice for applications with heavy media such as sludge, sandy water or bentonite.

According to Tsurumi, there have been numerous improvements to the rest of the product range, which includes around 250 pump models. A live demo of the permanently running pumps in the water tank turned out to be a visitor magnet.

Tsurumi submersible pumps can handle 8-mm sediment.

Siemens Discusses Digitalization

At this year’s bauma, Siemens presented possibilities for more digitalization in transport solutions (conveyor belt systems and haul trucks) with integrated systems under the motto “Take Transport in a New Direction—Discover the Potential of Digitalization.”

Before operating a belt conveyor system in the real world, Siemens uses digital models to virtually test and verifiy possible approaches for optimization. Whether physical components or digital expertise, Siemens discussed a high variety of mine transport solutions.

In keeping with the focus on digitalization, two Siemens solutions for haul trucks were also on display: the SiRAS program for remote access, and the Midas program for increasing equipment effectiveness.

SIRAS remote diagnostics hardware and software use Internet technology to allow Siemens service technicians and other experts to remotely log onto the truck from anywhere in the world and perform electrical work. Software upgrades, for example, can be downloaded to the truck and installed during the vehicle’s downtime. Important parameters and data can be monitored to deduce trends.

Consequently, maintenance can be planned before failures to avoid losses in production. The net result is a substantial increase of the mean time to repair, greater system availability and reduced maintenance costs.

Midas is a lever to help use trucks more effectively. It collects data during ongoing operations and uses this data to carry out analyses of production and optimize operations.

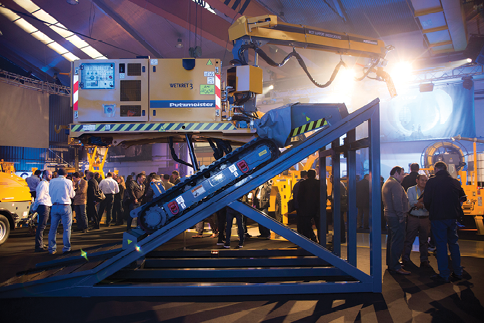

Putzmeister Unveils New Shotcreting Machines

Prior to bauma, Putzmeister’s Underground Division held an open house in Madrid and welcomed more than 300 guests from more than 30 countries. For the afternoon, a manufacturing facility was converted to a night club and guests were served Spanish wine and tapas while the company unveiled a new mechanized shotcrete spraying machine for narrow-vein applications (the Wetkret 3) and a compact shotcrete batching plant (Batchkret 20), specifically designed for underground mines.

Perfect for the rugged, uneven terrain found in tight headings, the Wetkret 3 is mounted on a compact rubber-coated crawler chassis. It has a telescopic spraying arm with a vertical reach of 9 m and a horizontal reach of 7 m, which can be deployed in a minimum width of 2.5 m. The machine can be powered by diesel

or electricity, boosting on-site mobility away from the mains.

The Batchkret 20 completes Putzmeister Underground’s shotcrete offering for a fully integrated, streamlined shotcrete application process. Designed for challenging operating environments, the Batchkret 20 allows miners to bypass costlier shotcrete transportation systems, by taking the production of concrete to the heart of their operations underground and optimizing logistics.