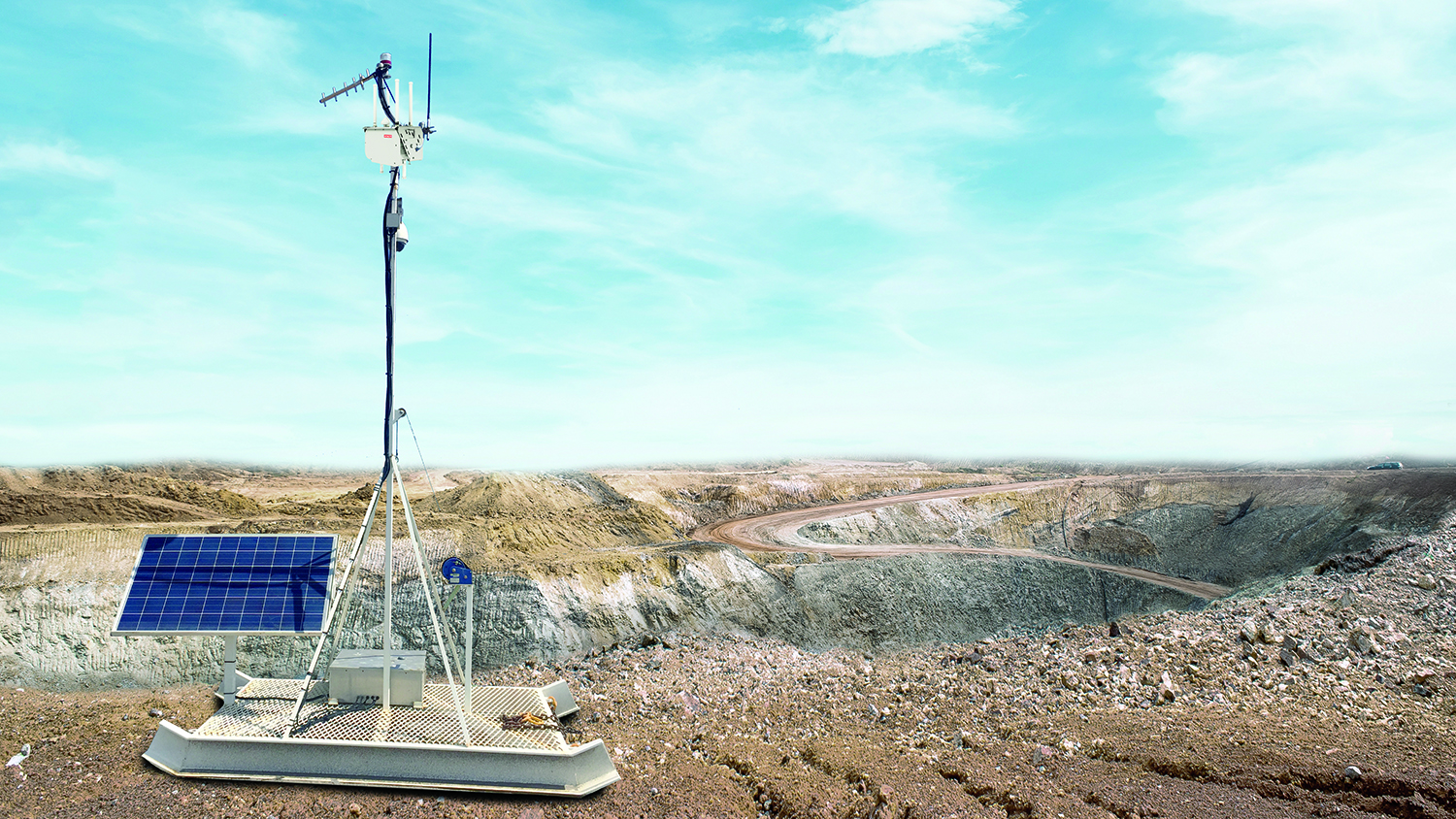

The TRO670 router for broadband mesh private networks and cellular connectivity can be mounted on a pole on a trailer and moved when needed. (Photo: Hitachi Energy)

New releases can support remote monitoring at almost any operations or work area

By Jesse Morton, Technical Writer

The newest wireless communications solutions offer several key capabilities and benefits. Critically, they can be used to support remote monitoring, which provides data for timely decisions and process optimization. The resulting efficiency gains can translate to cost savings and increased production.

Suppliers list several other capabilities that will also help miners generate revenue and win investors. According to them, major mining companies and equipment OEMs are either already deploying or will soon be.

Broadband, Cellular Anywhere

Hitachi Energy announced the TRO670, a pole-mounted industrial cellular router for broadband mesh private networks and cellular connectivity up to 5G. The solution was unveiled at DISTRIBUTECH International 2024 in Orlando, Florida, U.S.

Leadership at the company said the solution is “ideal” for open pit mining. “It is fully industrially certified for mission-grade-type security compliance,” said Mike Dulaney, global head of sales, wireless.

In appearance, the unit is “a hedgehog on a pole,” said Tore Gillbrand, vice president, global product management. It is 26 by 18 by 10 in. and “heavy, but you fit it on the pole and all you need to run up to it is power,” he said. “It weighs about 20 lb, has four antennae on top for mesh connectivity, has two antennae on the bottom for cellular connectivity, and has a little GPS receiver antenna in the middle of it as well.”

Compared to predecessor TRO600-series models, the TRO670 “has a larger enclosure that allows it to integrate partner radios,” Dulaney said. “It comes with an optional battery backup to allow for continuation of communications should the mine location lose power,” he said. “It is edge compute ready for application processing.”

Typically, with only three TRO670s a site can have a broadband mesh network, Gillbrand said. “And then they maybe build it out to a dozen, maybe 20 or 30 that they can drag around on trailers and move it as the pit is migrating.” A router can be sited “between the pit and the office, which is ultimately where the data will go.”

Such a network requires minimal configuration of the devices on it. “The devices only know that they are the members of the same mesh network and they will do their best to get their data to various takeout points in the network,” he said. “It is very automated, very simple, and it scales fantastically.”

The devices on the network are managed by a Hitachi Energy software system, Supros. “It eases the manageability, flexibility, security, performance and mobility,” Dulaney said.

The top-listed benefit offered is the ability to build and manage a private cellular network with minimal infrastructure. “That of course means that you get the benefit of operating on your private network when you can, and then you can fall back, without changing technology, to an operator-provided network if you move out of the main roads,” Gillbrand said.

“You can have a rather normal seamless communication,” he said. “There is always a little glitch when you jump from one network to another of course but if it is not time-critical then that is a fantastic benefit.”

Critically, a private cellular network built with the TRO670 will also support machine monitoring and machine-to-machine communications because the router is a layer-2 emulation solution, meaning it supports a data-link layer.

Most Industry 4.0 technology “developed assuming a layer-2 network connectivity, which is a local-area network” typically using WIFI, Gillbrand said. “The new TRO670 cellular router ‘tricks’ the applications into believing that they are directly connected, and they work as happily as they would if they were on a layer-2 network,” he said. “You get the benefit of scale. You get the benefit of being able to switch from the mesh network to a private cellular network, to a public cellular network, and that connectivity will simply continue.”

Another benefit offered is reduced infrastructure requirements compared to what is often required for the typical private cellular network.

“This is basically an outdoor, wide-area mesh technology, which means that the infrastructure and the points where you access the networks are the same,” Gillbrand said. “It is a very light structure and it can be easily moved in an open-pit environment.”

Previously, mining majors have used Hitachi Energy mesh network routers to build and grow networks that support machine monitoring, communications, and machine-to-machine data-transfer applications.

For example, an Australian coal operation needed “easy-to-relocate communications for mission-critical mining-management systems that had the capacity for additional applications, including fleet management and telematics,” Dulaney said. The miner adopted Tropos mobile broadband mesh routers for the heavy equipment. “The benefit that they got there was the real-time vehicle monitoring, fixed video monitoring, and the data transmitted for analysis.”

Mining customers benefit from the mobility of the solution. “Throughout our implementations in Australia, they would fit our radio and maybe a camera on a pole and stick that entire installation on a sled that they can drag around with a tractor and a couple of batteries and a solar panel,” Gillbrand said. “When I visited last time, they had been operating this particular sled for six years and all they did was to wash the solar panel every now and again because it was dusty and it reduced the charging capacity of it.”

The router trailers “provided regular WIFI access to whomever was close by,” he said. “Whether they were in the vehicle or walking around or doing anything else, they could get on the network.”

The setup was almost “infrastructure-less,” Gillbrand said. “Networks, while they benefit in many of our other application areas, they are hard to come by around open pit mines because they are typically very remote operations.”

At a site elsewhere, miners wanted near-real-time data and video from the mine and equipment to improve efficiency, safety and security. They adopted fixed mesh routers in and around the pit. The routers extended “the networks into the mine and to each of the control centers in the chemical processing plant at the mine,” Dulaney said. “The benefits to the customer include clear asset visibility for preventive maintenance,” he said. “It improves operational efficiency and safety.”

The networks are built on 2.4- and 2.5-GHz broadband mesh. “The reason why that communication media is so good for mines is it has a lot of bandwidth and very low latency,” Dulaney said. “What we are applying to the mining vertical is the same that we would be applying to any other of our industrial verticals, be it oil and gas or utilities.”

The TRO670 and the other TRO600-series solutions are the fifth generation of private mesh network solutions from Hitachi Energy. The series is designed to give customers more options and capabilities as technologies evolve and 5G is more widely implemented.

Telematics Anywhere

Intelsat previewed FlexMove Fleet, a new satellite service that supports on-the-move IP and telematics connectivity anywhere in the world.

“FlexMove Fleet is an end-to-end managed service just requiring a mining company to buy a data package and approved satellite terminal or terminals,” said Charlie Coates, Intelsat’s senior principal market development manager. The terminals can be “installed quickly on surface mining equipment providing connectivity and comms on the move, anywhere.”

FlexMove Fleet terminals are 604- x 290- x 41-mm, smaller than the predecessor FlexMove broadband terminals. The FlexMove Fleet terminal “is roughly the size of two laptop computers side by side,” said Scott Congdon, Intelsat business and market development manager.

The terminal is basically “a flat panel antenna, with no moving parts, which really doesn’t have much presence on a machine at all while enabling greater connectivity.” Power is supplied through an RJ45 cable that can also supply Ethernet.

The smaller terminal size means “you may be sacrificing throughput data speed versus the terminals used with Intelsat’s FlexMove broadband solution, which are larger, but nonetheless, you are still achieving data speeds of up to 1 Mbps up- and down-link,” Congdon said. “That is more than sufficient for fleet management needs of heavy equipment that is often found at a mining operation.”

The FlexMove Fleet terminal provides sufficient connectivity for “all the traditional telematics and machine communication coming off of that vehicle plus the ability to support on-demand video links, and voice communications,” he said. “And it does that at a very budget-friendly price point for both the terminal and the service.”

In development for roughly 18 months, the “terminal is an all-in-one piece of hardware that incorporates the antenna, the modem, all the other hardware needed for satellite communication,” Congdon said.

“You are not deploying outdoor and indoor pieces to this satellite terminal, instead it is an all-in-one terminal configuration,” he said. With an integrated WIFI router, the terminal “becomes the complement to a terrestrial cellular connection or becomes the sole point of connectivity for that vehicle for data received or sent from that vehicle.”

Either supporting a primary or fallback wireless communications link to the vehicle, the terminal serves as “another access point for critical information to flow on and off the vehicle,” Congdon said. “It supports connectivity for IoT sensors, a telematics system, a machine-to-machine data transfer management system, and voice over IP via the operator’s cell phone using WIFI,” he said. “There are multiple ways that you could connect multiple wireless devices to this satellite terminal to become either the primary or the complementary access point.”

The topmost benefit listed is what Congdon and Coates call the five nines. “It is available anywhere in the world with an availability of 99.999%,” Coates said. “When looking at the mining industry and a lot of other sectors, that is critical for safety requirements,” he said. “There is no downtime so that is sort of where satellite really comes into its own compared to even terrestrial networks.”

The five nines result in part from the advanced design of Intelsat’s geostationary-orbit (GEO) high-throughput satellites. “Because we can focus energy down to a much smaller beam projected to the earth’s surface, we can drive higher speeds to very small terminals,” Congdon said.

A GEO network does have higher latency than does a medium- or low-earth orbit network, which may impact certain user apps. “So Intelsat, after initially launching FlexMove Fleet with a GEO-only solution, will be moving towards a multi-orbit solution, where we will integrate into the FlexMove Fleet connectivity solution a GEO with a low-earth-orbit (LEO) and possibly medium earth orbit (MEO) link or links,” Congdon said.

With a “LEO and MEO connection you end up with even higher data throughput,” he said. “When you get to multi-orbit integration you’ll be looking at multiples of Mbps delivered to same small terminal.”

The FlexMove Fleet terminal is rugged and optimized for use in tough environments, Intelsat said. The terminal can support of “over-the-air software and firmware updates and upgrades to the vehicle or other data management tools onboard.”

The solution is also “ultra-secure,” Congdon said. “The same network that we deliver for commercial use and service is also the same network and platform that we use in support of U.S. government and military users,” he said. “We control our teleports, our satellites, and our own MPLS fiber network between our teleports.”

FlexMove Fleet recently completed field trials spanning roughly eight months. The trials enabled developers to “better optimize the design and capabilities of the network, service and terminals,” Congdon said.

The trials were “focused more on telemetry and low-data rate asset management applications,” Coates said. “We will soon begin trials to support remote control of excavators and dumpers at remote mining and construction sites in support of a number of OEMs.”

Remote control is “a priority of those OEMs and their customers,” Coates said. “Intelsat is leading the way with them to support that use case as well.”

Gas Monitoring at the Face

Conspec Controls said its new gateways can be used to build hybrid networks that are scalable for customers interested in incremental adoption of their wireless atmospheric monitoring solutions underground.

“The hybrid network allows for mines that are currently using the Conspec system to venture into wireless technologies without jumping in head first,” said Tanveer Jahir, B.Eng, P.Eng, international business development manager, Conspec Controls.

“We at Conspec understand the importance of reliability when it comes to gas monitoring underground,” he said. “Every second matters, and because we understand that, we also understand the hesitancy in trying technology that can occasionally have ‘hiccups.’”

The hybrid network allows hesitant customers with a wired Conspec Controls network to trial wireless communications in certain areas. “Our hybrid network allows you to use your existing infrastructure, all the while taking advantage of wireless ‘hops’ to get the most and best of both worlds,” he said.

The new gateways can talk to wireless gas monitors. “These gateways can be installed on your existing cable network,” Jahir said. “To the front-end software, it sees the wireless unit as if it was wired, seamlessly,” he said. “Our gateways take care of the polling to the wireless gas monitors, and ensure that you have a strong dependable backbone, the cable network, to quickly and reliably send the data to the surface.”

The ease and simplicity of adoption means the gateways can be deployed with comparatively reduced risk. “One of the key features is the use of existing infrastructure,” Jahir said.

“Our hybrid network doesn’t require you to install a full new system to make the most of wireless technology and gas monitoring,” he said. “It will work on your existing wired AMS.”

By trialing wireless atmospheric monitoring solutions in one area first, customers can then determine where, when, and how many to deploy later. “The end user isn’t forced into using technology that is still relatively new to them,” Jahir said. “They can slowly get their feet wet with the technology until they are comfortable enough to use it through the mine,” he said. “It’s a nice stepping stone to a full blown wireless network.”

The gateways also allow the installation of monitors in areas where it could be challenging or problematic to run cable. “Safety improvements come from being able to measure air quality in areas where the existing cable network won’t allow you to go,” Jahir said.

“Instead of running cable into every corner of the mine, you can run your existing cable with short wireless hops into areas that may be hard to reach for the cable,” he said. “This increases your gas monitoring coverage, without the cost of deploying full-blown infrastructure.”

For example, a wireless area could be the cutting face. “Having gas monitoring at the cutting face can help the miner feel confident and secure that the area is not only being monitored from the surface, but can also provide local alarming at the face,” Jahir said. “A safe miner is a productive miner.”

Conspec Controls wireless gas monitors are commonly “used for post-blast applications,” he said.

“These monitors are installed right at the face of the blast and allows the mine to see the real-time decay of the gases from the blast,” Jahir said. “This increases the safety of the miners as well as productivity by allowing the miners to return to work quicker, all without the need for installing expensive infrastructure.”

The new gateways are expected to be approved by the Mining Safety and Health Administration.

Conspec Controls launched more than a half century ago and quickly specialized in developing atmospheric monitoring solutions. “We understood how to develop products and use technologies that would not only be affordable, but also robust and long lasting,” Jahir said.

“Many of the solutions in underground mines in the U.S. have had the Conspec system for over 30 years,” he said. The gas monitors are designed to work on any existing Conspec networks.

“We understand that in order for you to use new technology, you shouldn’t have to completely remove all of your existing infrastructure,” Jahir said. “We followed that philosophy into developing our wireless gas monitors to ensure that it would work on existing systems, thus being complimentary to the system.”

Last-mile Connectivity

Maestro Digital Mine leadership said Newmont Corp. is planning to expand its deployment and use of Plexus PowerNet, a last-mile network solution.

“Initially, our solution was deployed at a single mine site,” said CEO-in-Training Jacob Lachapelle. “However, the impact and benefits it delivered were so significant that Newmont has since expanded its use to other underground operations, including Cerro Negro and Hoyle Pond, and is now planning to implement it elsewhere.”

The development highlights Plexus PowerNet’s ability to quickly extend communications to exactly where needed, a capability that is in demand by Newmont and other majors, said COO Jahanzeb Sohail. “Mines are having a challenging time growing their networks at the speed of production.”

Plexus PowerNet “is specifically designed to address the critical challenge mines face in keeping their network infrastructure advancing at the rapid pace of production,” he said. “It not only streamlines the process of expanding network capabilities but also ensures that the technological foundation of the mine can scale flexibly with production.”

“The simplicity of this network distribution system appeals to miners who are looking to enable safety and productivity technologies that otherwise struggle with deployment at the last mile to the face,” he said.

Plexus PowerNet is a high-bandwidth, low-latency, coaxial communication infrastructure solution that “provides a robust, easily deployed, one-cable solution for network connectivity,” Lachapelle said. “Plexus makes installation simple, using a single coaxial cable that carries both power and network connectivity,” he said. It eliminates the need to run both fiber and electricity. “The Easy Advance Nodes provide an effortless way to terminate, troubleshoot and deploy standards-based IP devices from the Plexus PowerNet embedded network switch.”

The solution enables the mine to deploy critical technologies, such as air quality monitoring solutions, to the face.

“Maestro Digital Mine cut our teeth as a company in developing air quality monitoring stations for the underground mining industry,” Lachapelle said. “These IIoT devices, generally installed in the last-mile towards the working face, require power and connectivity.”

The stations are proven and user-friendly, but weren’t seeing maximum use. “While mines acknowledged that the equipment was easy to install and use, the devices were being held up in the warehouse for another reason,” he said. “The mines were constrained in timely deploying network and power utilities at the pace of production.”

Above, Trent Woodcock with NLT Digital, standing on left, and Jason Miler, right, with Matrix Design Group, advise Matrix’s Jarrod Farris, seated, who is programming networking equipment.

The result was the limitation of “the safety and productivity benefits of the technology,” Sohail said. “Further, we learned that we were not alone in this challenge.”

For example, “in a recent exchange with a well-known Canadian miner, it was shared that they have completed 30% of mining activities in the active section and have yet to deploy high-value IIoT technologies,” Lachapelle said.

“Their progress is inhibited by the current network,” the expansion of “which trails behind production speed,” he said. “When network and power utilities are finally deployed on the level, it’s too late, and mining activities have typically shifted to another area of the mine.”

Plexus PowerNet answers that challenge and, therefore, helps improve safety and productivity at the face, he said.

The topmost benefits listed are ease of installation and improved safety. “Its ease of installation, advancement, and repair, which can be managed by electricians and most development miners at the working face, makes Plexus PowerNet an essential tool in enhancing miner safety and productivity,” Sohail said.

Some of the safety benefits offered stem from its ability to support remote control. “Our solution has been pivotal in enabling tele-remote operations of LHDs,” Lachapelle said.

“This optimizes production efficiency by allowing continuous operation, irrespective of shift changes or breaks, and significantly enhances worker safety,” he said. “By relocating operators from the underground environment to a remote-control center, we’re minimizing their exposure to hazardous conditions, such as unstable ground and airborne particulates.”

The solution can also support proximity-detection systems. “Our technology has been instrumental in the establishment of safety barriers,” Sohail said.

Bridging the Gap

Matrix Design Group said it recently installed a high-speed data network system at a Midwest metal-nonmetal mine. The system provides tracking and connectivity, including to cameras and voice-over-IP radios.

The mine’s plan is to bring data from the face and equipment to operators, leadership, and the back office for analyses of processes. Reporting software will support those analyses and support timely decisions on process optimization and workplace safety. Anticipated benefits include lower costs, enhanced functionality, and increased efficiency, leadership at the supplier said.

“Bringing high-speed data underground opens up a large technology door for mining operations,” said Chris Adkins, manager, mining. “Matrix Integrated Networking Solutions technology helps bridge the gap between surface operations and the underground operations so that they can see what is going on in real time with the equipment and people that use it.”

The SENTINEL Unity Node supports voice, text, tracking and WIFI. (Photo: IWT)

The Advantages of Integrated Wireless Communications

By Chad Barnett

Since the MINER Act passed in 2006, digital systems using wireless mesh networks have revolutionized safety in mining. However, in addition to providing MSHA-approved communications and tracking coverage, fully integrated and customizable wireless mesh networks can also provide other valuable benefits such as simplified installation and maintenance, increased productivity, and efficiency gains through the availability of real-time data and remote monitoring. All these benefits result in a more reliable system with an overall lower total cost of ownership for the customer.

Wireless mesh technology is a self-forming network. Radio networks establish the routing through the mesh links as the equipment is installed. Since cabling is not required, this allows for greater flexibility, reliability, and rapid deployment of equipment.

Mesh networks are also self-healing, which provides inherent redundancy. If one connection fails or is blocked due to interference, the mesh network will automatically reroute traffic through other redundant links, ensuring continuous communication. This resiliency is crucial in safety-critical environments where uninterrupted connectivity is essential for emergency response or ensuring personnel safety.

Wireless mesh networks also provide benefits with their scalability and flexibility in coverage. Since they are decentralized and not reliant on a single central server, wireless nodes can be placed in any number of locations, providing enhanced coverage including in hard-to-reach or remote areas.

Real-time Data and Asset Tracking

Wireless mesh networks can provide mine operators with the benefits of real-time monitoring of their operations, enabling data-driven decisions based on production status, asset tracking, and environmental conditions; and supporting the ability to measure and optimize operational performance. With better data-collection capabilities, mesh networks support robust analytics programs that help minimize safety and business risks, capture trends in production and labor, correct maintenance issues, and optimize performance and overall efficiency.

One example of how mine operators can successfully use real-time data is through preventive maintenance. This type of program can monitor and track equipment performance in real-time and predict potential maintenance issues before they become major problems, helping mine operators avoid downtime and costly repairs.

Another data-collection program supported by wireless mesh networks is asset tracking. Automated location services provide asset-tracking information to determine optimal usage routines, while personnel tracking provides critical information for emergency purposes. Asset tracking can give production data, status updates, and, through integrated analytics, actionable information.

Remote Monitoring

Wireless mesh networks also allow for the remote monitoring of mining sites. This reduces the need for personnel to physically perform site visits, resulting in increased safety and efficiency. Additionally, with the integration of broadband backhaul connectivity, aboveground dispatch network operation centers support mine operators in monitoring the status of the mine, communicating with workforce personnel, remotely monitoring personnel and assets, and responding to potential emergency situations.

Another benefit of remote monitoring for mine operators is more efficient system maintenance through programs like maintenance analytics. With these types of programs, diagnostic tools are provided to maintenance personnel in assessing the network’s overall performance and identifying areas for improvement. Since the analysis of the RF network is automated, the time needed to identify areas within the network requiring attention is significantly reduced.

A wireless, battery-powered gas monitoring system, with long battery life, can be used as an economical solution to monitor the atmospheric conditions in remote or abandoned areas of the mine.

IWT Sentinel

One example of an advanced, digital networking, wireless mesh system is the Sentinel Communications and Tracking System from Innovative Wireless Technologies (IWT). This system encompasses all the benefits of a wireless mesh network to provide customers with a system that is highly reliable, scalable, and easy to maintain, with superior performance.

With the system, a network of nodes act as repeaters to wirelessly send voice communications, text messages, real-time tracking, environmental sensor information, machine health, and productivity data throughout the network both underground and to the surface.

Rugged, MSHA-approved, push-to-talk handset radios provide clear voice and text communication as well as tracking capabilities for users underground. The continuous tracking of personnel, vehicles and assets is supported on the same network in real time.

The value of a seamless, integrated system compounds as more capabilities are included. The Sentinel System can be leveraged well beyond providing communications and tracking with additional capabilities that include wireless gas monitoring and ventilation modeling, remote atmospheric and environmental monitoring, tools for production and maintenance analytics, proximity detection, predictive compliance, and more.

Chad Barnett is Product Manager for IWT.