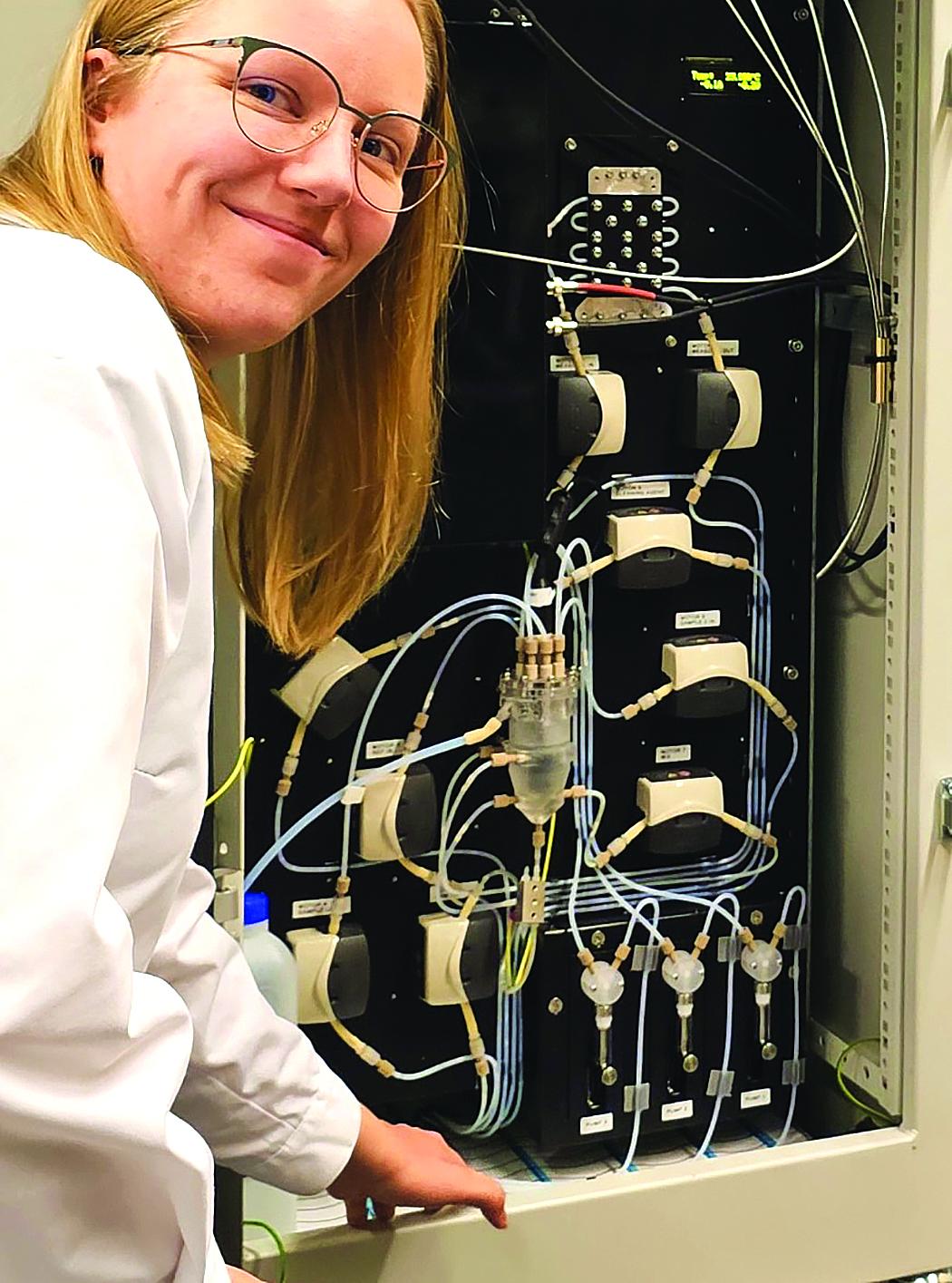

Sensmet claims its µDOES analyzer, shown here, can streamline the measurement process compared with off-line laboratory ICP-OES methods, providing comparable performance to the traditional approach but also offering the capability of continuous and fully automated industrial process monitoring. According to the company, µDOES drastically reduces maintenance requirements due to the absence of components such as RF coils, spray chambers or nebulizers needed for ICP-OES.

Sensmet, a Finnish company specializing in real time analysis of battery metals, recently reported that its continuous metals monitoring technology has been evaluated in a field trial conducted by a major mineral processing equipment supplier. The trial, according to the company, compared lithium and sodium measurements by laboratory Inductively Coupled Plasma – Optical Emission Spectrometry (ICP-OES) analysis with the Sensmet µDOES continuous analyzer, and demonstrated excellent correlation between the two different methods.

During the trial, samples were taken from a process in which battery-grade lithium hydroxide monohydrate was produced from spodumene concentrate treated by high-temperature conversion in a rotary kiln. The hydrometallurgical technology, developed by Metso, produces battery-grade lithium hydroxide monohydrate by soda pressure leaching. In this application, the analytical performance of the µDOES analyzer was evaluated for the continuous optimization of pressure leaching and conversion leaching.

Sensmet said more than 60 samples were drawn from the process and analyzed by a µDOES continuous analyzer and a laboratory ICP-OES. Sodium and lithium concentrations were measured in each sample, and the results showed an excellent degree of correlation between the online instrument and laboratory reference analysis. The calculated R2 (coefficient of determination) for the two elements were 0.98 for the lithium comparison and 0.95 for sodium.

“We were impressed by the outcomes of the measurement campaign, conducted in a challenging environment replicating real-life conditions. Despite the rigor, the µDOES and ICP-OES delivered congruent results,” explained Metso’s Vice President – Automation Product Group, Veli-Matti Järvinen. “This is significant – we anticipate that the µDOES technology will bring substantial value to the realms of battery metal production and recycling processes when integrated to Metso Courier HX system.”

The trial was conducted by Metso at its facilities in Pori, Finland. Metso said it will adopt µDOES technology in selected Courier HX systems for Li and Na analysis, and the new systems will be available globally in 2024.

Sensmet said the patented µDOES technology is based on atomic emission spectroscopy. A micro-discharge (electric spark) is created directly inside the aqueous sample, causing a microscopic volume of the fluid surrounding the spark to be flash-heated to 10,000°C. Molecular species in the micro-discharge are dissociated into atoms, which are excited to their respective higher electronic states. Upon returning to their ground state, these atoms release their excess energy by emitting light at their characteristic wavelengths. The µDOES measures this atomic emission spectrum to derive quantitative analysis of the metals contained in the sample.

µDOES is able to continually repeat these measurements with a user-selectable measurement interval of 5 to 30 minutes.

Summarizing, Sensmet CEO Toni Laurila commented: “The third-party evaluation shows how µDOES technology allows operators to consistently produce high-quality, continuous 24/7 measurements, akin to results obtained in a laboratory. This capability is accessible directly at the process plant, avoiding the delays of lab analyses, and exploiting the benefits of real-time process monitoring.”

According to US Critical Minerals Corp., its Sheep Creek property in southwest Montana is one of the highest-grade light rare earth projects known within the US with average total rare earth element content of 6.8% across 51 historical samples.

Also in December 2023, Idaho National Laboratory (INL) and US Critical Materials Corp. announced a multi-phase collaborative project to develop a process for carbonatite ore handling, preparation, and extraction of targeted, value-added metals present in the ore. This process, according to a press release, can be achieved by invoking a combination of conventional, newly developed (within the past decade), and emerging materials handling and separation processes.

The focus of the agreement, said US Critical Minerals – a Utah, USA-based private REE exploration and development company – is on developing solutions for dealing with and solving the environmental issues related to mining and processing. INL is managed by Battelle Energy Alliance for the US Department of Energy.

The two parties intend to form technical teams to evaluate state-of-the-art separation technologies. As part of their evaluation, they will commission targeted Research, Development, Demonstration, Testing & Evaluation (RDDT&E) of separation technologies useful for achieving economic, environmental, and performance efficacy targets provided by US Critical Materials Corp.

Technologies developed by the project could result in intellectual property that may lead to new patent filings at the conclusion of the eight-month term of the current cooperative research and development agreement.

The company noted that carbonatites – igneous rocks composed of carbonate minerals such as calcite and dolomite – have been the primary source of niobium and rare-earth elements for decades, particularly the light REEs, including La, Ce, Pr, and Nd. Over 50 surface carbonatite occurrences have been documented and sampled at Sheep Creek, US Critical Minerals’ southwest Montana land holding that encompasses 223 lode claims representing approximately 4,500 acres.

The Sheep Creek carbonatites, according to the company, are up to 3 meters (m) wide and can be traced for more than 200 m along strike. Important ore minerals identified include ancylite, allanite, monazite, and columbite. Historical grab and chip sampling of carbonatites indicate the potential for high-grade mineralization with up to 18% total rare earth elements, including 2.4% combined neodymium and praseodymium, plus credits in niobium and other strategic metals.