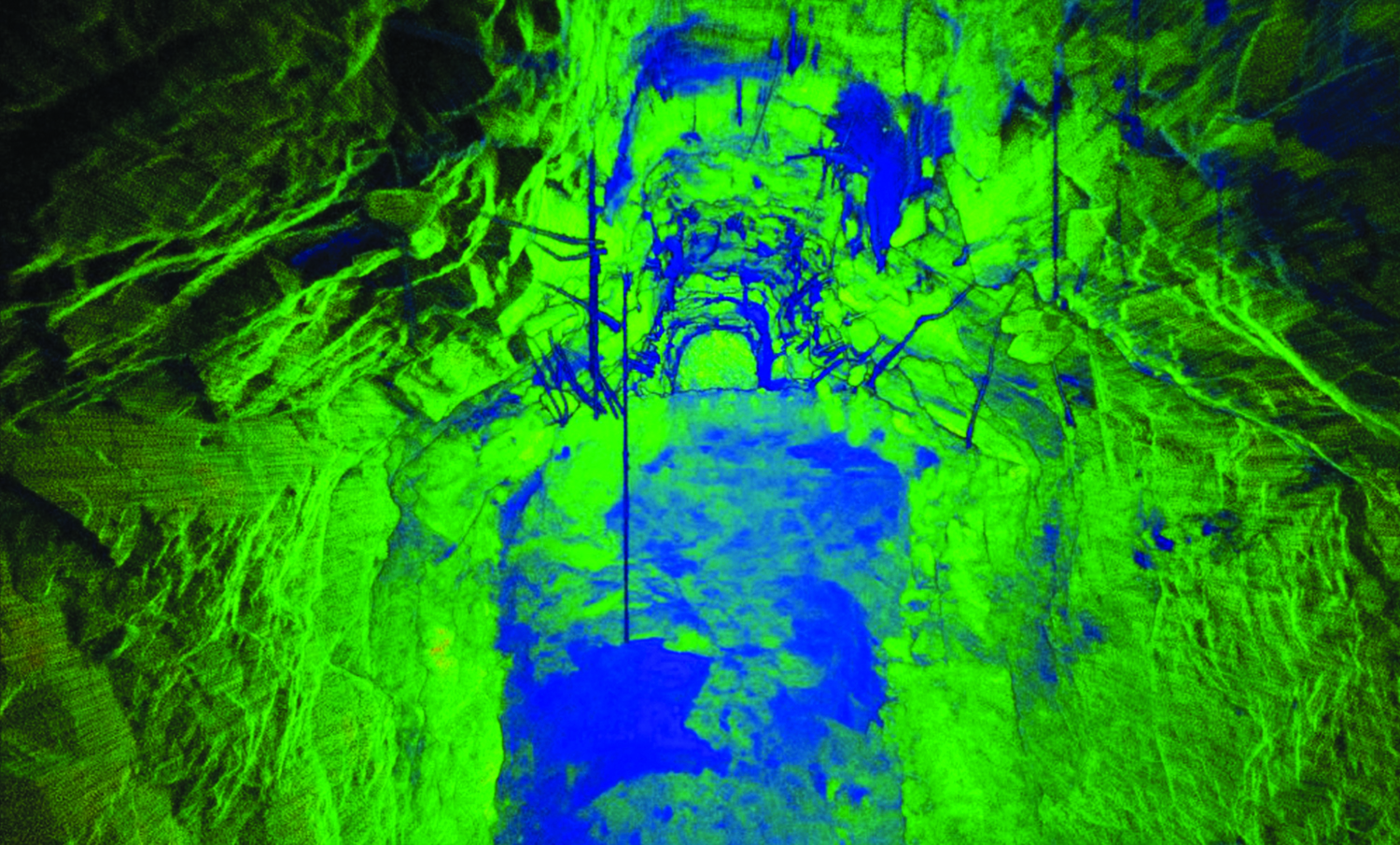

As shown in this stope scan image, Hovermap’s rotating LiDAR provides a wide field of view, ensuring 3D data is collected in all directions.

A recently released white paper from high-tech drone technology provider Emesent details how BHP’s adoption of mobile LiDAR technologies, such as its Hovermap, at the company’s Olympic Dam mine in South Australia has delivered numerous benefits. The paper, available at Emesent’s website, indicates drone usage is helping to de-risk the transition of mining activity from the older and well-understood Northern Mining Area (NMA) to the newer Southern Mining Area (SMA) by providing unprecedented insights into the new rock mass.

Hovermap is a smart mobile scanning unit, which can be handheld or mounted to a variety of equipment types to provide autonomous mapping in risky or inaccessible areas. Its quick-release mechanism makes it easy to switch from drone to handheld use, enabling the collection of critical data both in the air and on the ground, with the ability to automatically merge the results. Weighing just 1.8 kg, it is portable and compatible with smaller drones such as the DJI M210.

Being able to safely scan previously inaccessible voids, stopes, drawpoints and orepasses allows BHP’s survey, geology, engineering and geotechnical teams to validate and improve modelling, optimize stope design and predict stope behavior more accurately.

Emesent said Olympic Dam has continued to find additional use cases for the Hovermap system and the LiDAR data it captures. For example, it is now used across the mine to map the ore handling system and other vertical infrastructure and identify convergence and other deformation.

Training and regular use of the system in situ means operators are able to capture data confidently and competently via a range of methods — vehicle, tether, handheld and drone. End-users’ ability to analyze and utilize the LiDAR data has also increased significantly over time.

In addition, the multidisciplinary approach to deploying Hovermap and sharing data has encouraged collaboration across technical teams at the site and led to the development of efficient new workflows. And, according to Emesent, Hovermap is helping BHP optimize revenue at the site. Based on production output published by BHP in 2020 and LME commodity prices for that year, Emesent estimates average revenue (EBITDA) per stope of $20 million. The insights gained from data captured by Hovermap help BHP to improve confidence in the drivers of stope stability, and to develop informed responses to issues.

This potentially saves the company millions of dollars each year.