Miners and mine suppliers will converge on the Las Vegas Convention Center for MINExpo 2021.

The NMA hosts the world’s largest mining trade show in Las Vegas

By Steve Fiscor, Editor-in-Chief

MINExpo INTERNATIONAL will kick off for three days starting September 13. Attendees will see some of the largest equipment on Earth without leaving the Las Vegas Convention Center. Much has changed for the mining business since the last event in 2016. Metal miners have seen considerable market improvement, the coal sector is recovering from a significant drop in demand, and aggregate producers are chasing a runaway construction market.

The National Mining Association (NMA) produces MINExpo. Proceeds from the event help fund the NMA and its mission to represent mining in Washington, D.C., on both sides of the aisle. From a policy standpoint, their job has never been as important as it is today. Emissions reduction has become an environmental focal point now and miners will be called upon more than ever to supply the minerals critical to this transition. Infrastructure is also a hot topic and miners will supply the natural resources that support those efforts as well.

The mindset of the modern mining professional, whether it be an executive, an engineer, a metallurgist, or a geologist, has also changed in the last five years. The previous goals of building consistently larger equipment and systems to achieve economies of scale have given way to smarter mining and processing. Autonomous and assisted mining systems are now a reality now. Inexpensive sensors and the Internet of Things (IoT) provide a wealth of information that has led to system wide optimization.

The digitalization era is upon us. Tomorrow’s miners will use data and technology to study the influence of decisions on mines and processing plants. Artificial intelligence will allow them to see the trends that lead to break downs long before they happen. Advances in mineral exploration will reduce the footprint of prospectors as they search for the next big discovery. All of that and more will be on display at MINExpo 2021.

Celebrating a Mining Renaissance

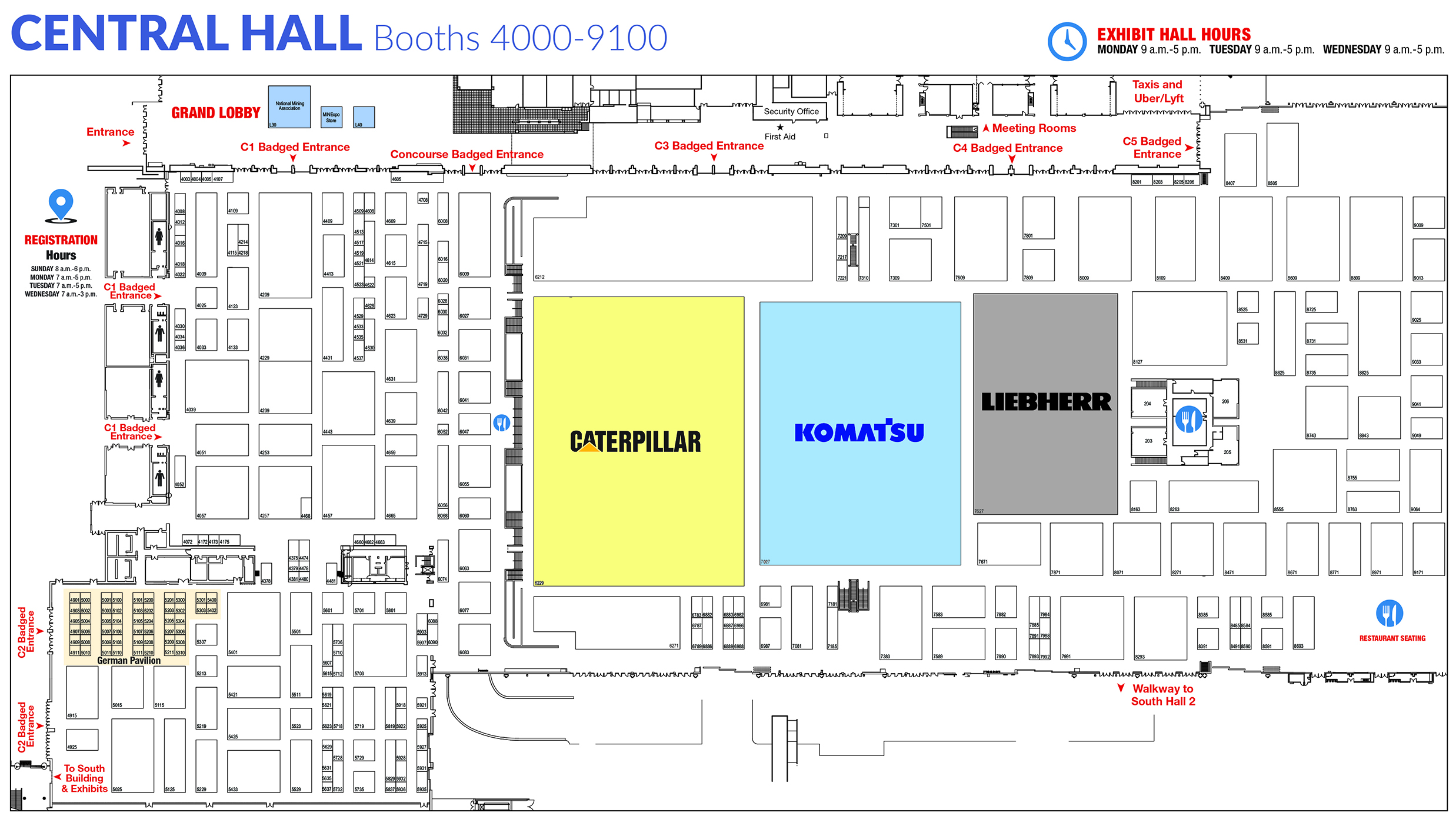

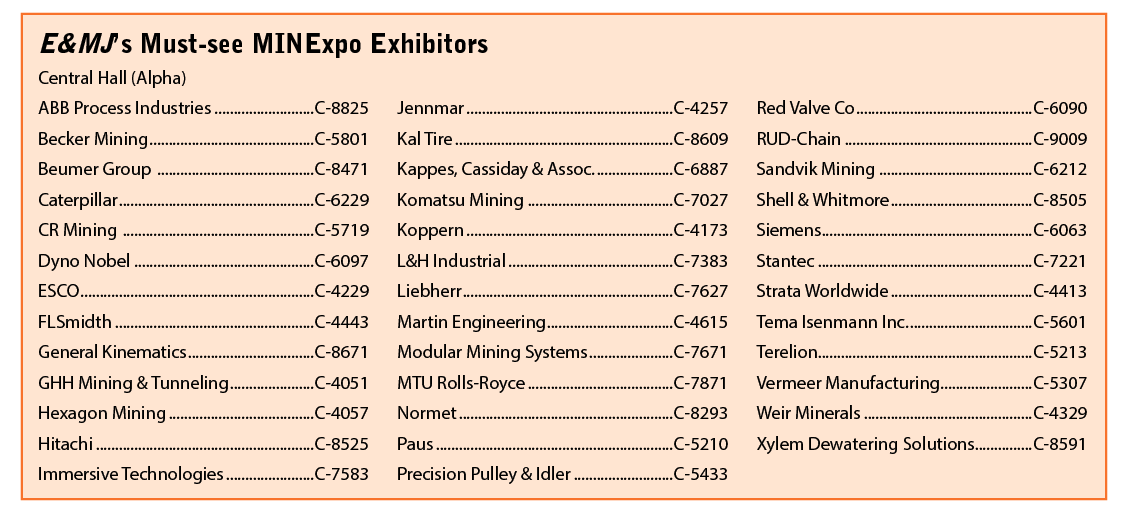

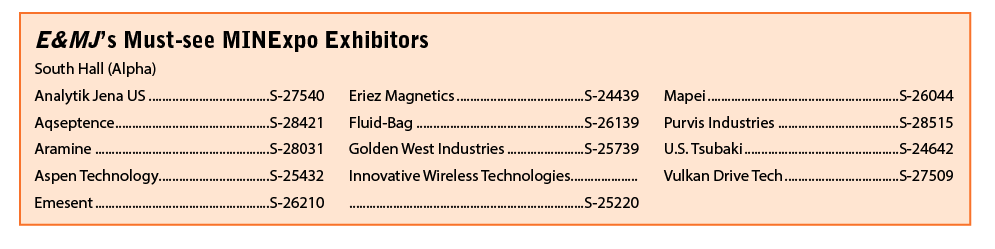

When the NMA opens the gates for MINExpo 2021, visitors will get a chance to see more than 1,400 companies exhibiting mining and mineral processing equipment and technology. The exhibit spans three halls (Central, North and South halls) and 660,000 ft2. Organizing, postponing, and reorganizing the event required a substantial amount of work and patience, but the day has finally arrived.

Rich Nolan, president and CEO for the National Mining Association.

“MINExpo is really important to the NMA for many reasons,” NMA President and CEO Rich Nolan said. “Yes, proceeds from the event support the NMA’s mission, but beyond that, it galvanizes the industry. Even though mining operations are diverse, and their needs differ by region, this is a period, the post-pandemic era, where the market demand for minerals came roaring back and the forecasts in general look rosy. There is a mining renaissance taking place and MINExpo gives us an opportunity to showcase the equipment and technology used for mineral extraction. We’re thrilled to be back in Las Vegas conducting business in person and celebrating what mining brings to the world as the global economy gets back on its feet.”

Nolan was appointed president and CEO of the NMA in September 2019. He has worked for the NMA for 14 years and previously served as the senior vice president for government and political affairs. This will be Nolan’s third MINExpo and his first as the leader of the association. It’s also safe to say that, with his background, Nolan understands the importance of making sure that the mining industry’s voice is heard in Washington, D.C.

“Everyone is excited about the exploding demand for battery minerals, such as lithium, cobalt and graphite, but policymakers in Washington need to understand that the rest of the world is also pursuing these critical minerals,” Nolan said. “Part and parcel to this discussion is our ability to permit and open new mines and we need timely government approval to do that. The NMA is laser focused on working with both Democrats and Republicans in the Congress and the Biden administration on improving the permitting process and the reforms that need to be brought forward.”

The NMA is also making progress with the infrastructure program that’s currently under consideration, Nolan explained. “Steel is an important aspect of infrastructure and that requires iron ore from mines in Minnesota and metallurgical grade coal from Appalachia,” Nolan said. “We have worked with the Biden administration with two executive orders on supply chains

and the demand and importance of mineral extraction here in the U.S., an emphasis that is essential if we are going to meet the Biden administration’s future electrification and energy goals. It’s an exciting time. We’re in the middle of it every day.”

MINExpo will showcase the latest equipment and technology for mining and mineral processing.

From an exhibition perspective, MINExpo 2021 already has more companies booked than they did last year and the NMA is hoping that registrations build over the summer months. “We are working with the Las Vegas Convention Center, the city of Las Vegas and the Centers for Disease Control to exceed the guidelines for hosting the safest event possible. The mining industry is a close-knit community and we’re ready to meet in person again and MINExpo will be a perfect venue for that.

“The NMA advocates for technology as a real opportunity to improve safety and increase efficiency at mining and mineral processing operations,” Nolan said. “The technology on display will be essential in accomplishing these goals moving forward. Autonomous equipment, battery-electric vehicles (BEVs), advanced monitoring systems — all the technology we will see at MINExpo 2021 is the future of mining.”

The Future of Mining Technology

One of the companies that will be displaying the future of mining technology will be Komatsu. Jeff Dawes, CEO of Komatsu Mining, also serves as the MINExpo 2020-2021 chairman. Dawes said he was flattered when the NMA Executive Committee unanimously nominated him for the chairmanship, and he said he was very proud personally to serve in that role and to represent Komatsu.

“Last year was difficult for everyone,” Dawes said. “The decision to postpone the event was a difficult one too.”

Dawes has attended every MINExpo that has been hosted in Las Vegas, which would be seven including 1992. That would be almost all of them. The first MINExpo as it is now known, was held in Chicago in 1988. He has participated on the NMA board since 2017 and he has been a member of the executive committee since 2018.

“MINExpo is a big event logistically,” Dawes said. “Some of the major equipment manufacturers start shipping equipment to Las Vegas in April for a September show. Last year, in April 2020, no one knew what the future held, and we had to take the postponement decision early. The NMA staff has been outstanding in their dedication and their efforts to work through this situation with ever-changing conditions. The decision was difficult, but it was the right decision.

Jeff Dawes, CEO of Komatsu Mining and MINExpo 2020-2021 chairman.

Digitalization, electrification, and automation were the words Dawes used to describe the prominent trends delegates would see at MINExpo 2021. “Full-enterprise systems for mine-wide optimization can only be achieved if you connect technology with the processes and the people across the full value chain,” Dawes said.

“The solutions that leverage those three areas are key,” Dawes said. “They will also play a critical role in sustainable systems that support mining in a responsible manner. That will be a recurring theme for the event and certainly for the Komatsu stand.”

Dawes believes that mining suppliers can advance as quickly as leading mining companies expect them to. “These are exciting times when it comes to sustainability and the creation of new mining solutions,” Dawes said. “There is a growing recognition of the critical need amongst society to reduce emissions and conserve natural resources. The mining industry needs to contribute to these sustainable solutions, and it has become one of the highest priorities for mining companies and their suppliers.”

Komatsu and the other suppliers have rapidly begun exploring new innovative technology and solutions to meet the requirements in this new highly energy-conscious and eco-friendly future. “The industry is more than ready to meet those needs,” Dawes said. “We are at the leading edge of sustainability initiatives and people will definitely see that at the show.”

Acknowledging that the mining industry sometimes gets a bad rap, as being old fashioned, behind the times and energy polluters, Dawes said that’s simply not true. “There are roughly 15,000 ultra-class haul trucks operating worldwide,” Dawes said. “Of that fleet, 750 are operating fully autonomous, which is about 5%. Last year, fully autonomous trucks represented 30% of Komatsu’s total truck sales. There is a major shift taking place in open-pit mining.”

Operating large, heavy equipment autonomously is not a widely understood concept and mine operators are leading the way, Dawes explained. “The whole notion that mining is a backward industry is simply not true,” Dawes said. “And it’s not just the mining aspect of our business. We use the latest technology in plants to automate processes, and monitor and maintain equipment, to deliver more product safely and in a cost-effective manner that respects the environment.”

The technology that the mining industry is using today is cutting edge, Dawes explained, and now we’re starting to focus on zero emissions equipment from the largest trucks to smaller underground equipment, and people will also see that at the show. As far as zero-emissions operations, he believes the mining industry will be there soon.

As this edition was going to press, Komatsu announced it had formed a Greenhouse Gas (GHG) Alliance with several major mining companies, including Rio Tinto, BHP, Codelco and Boliden to collaborate on product planning, development, testing, and deployment of the next generation of zero-emission mining equipment and infrastructure.

The alliance’s initial target is to advance Komatsu’s power agnostic truck concept for a haulage vehicle that can run on a variety of power sources including diesel electric, electric, trolley (wired), battery power and even hydrogen fuel cells. The company’s initial concept is set to make its official debut at MINExpo 2021. Komatsu is targeting a 50% reduction in CO2 emissions from the use of its products and production of its equipment by 2030 (compared to 2010 levels) and has set a challenge target of achieving carbon neutrality by 2050.

These advancements are not limited to open-pit mining. “The same concepts apply, maybe even more so, to underground mining and that’s why Komatsu has made this commitment to offer mining companies equipment that allows sustainable emissions-free operations across the board,” Dawes said. “It promotes a healthier working environment underground, it saves the mines money on ventilation and development costs, and it’s better for the environment.

This is the first MINExpo since Komatsu acquired Joy Global. The acquisition was announced in July 2016 and the transaction was completed in April 2017. “Last time we presented ourselves as two separate companies and now we’re fully integrated,” Dawes said. “Everyone will see one Komatsu at MINExpo 2021. We will be there as Komatsu along with subsidiaries, such as Modular Mining, Immersive Technologies, Hensley, etc., in pretty much the same space.”

Komatsu has designed the experience so visitors will see the integration of the subsidiaries, which will flow through their stands to the main Komatsu stand, Dawes explained. The theme will focus on the three factors Dawes mentioned earlier: automation, electrification, and digitalization, highlighting the equipment on the main stand with the same look and feel as the other stands.

“We can now provide a full range of equipment for above and below ground mining applications,” Dawes said. “The opportunity we have had over the last four years to integrate into Komatsu the incredible manufacturing experience of well-known brands such as P&H and Joy now allows us to provide complete mining solutions.”

The mining industry has a strong sense of community. “MINExpo offers us a chance to mix and mingle with other mining professionals, share experiences, best practices and our visions for the future,” Dawes said. “COVID-19 illustrated that mining is essential. Working remotely was not an option for the mines or the major equipment manufacturers. We are all looking forward to a chance to get back together as an industry again.”