The 95-m high and 330-m wide Fábrica ECJ is designed to withstand the simultaneous rupture of five upstream dams.

Brazil miner decharacterizes Fernandinho dam and builds containment structure

During mid-July, multinational miner Vale reported it had completed the decharacterization work for the Fernandinho dam, located at the Abóboras mine at its Vargem Grande Complex, in Nova Lima, Brazil. The company also said it completed the construction of the downstream containment structure that serves the Forquilhas I, II, III, IV and Grupo dams and is located between the municipalities of Itabirito and Ouro Preto in Minas Gerais, near the Fábrica mine. The completion of both projects symbolizes progress the company has made with its commitment toward actively managing its dams.

Decharacterization of Fernandinho Dam

With the completion of the work, which will be evaluated by the competent bodies, Fernandinho no longer has the characteristics of a dam, losing its function of tailings and water storage. The decharacterization process involved removing 558,000 cubic meters (m3) of tailings and the installation of a central drainage channel with subsequent revegetation and reintegration of the area into the local environment. The activities employed about 540 workers, who mostly reside in the Nova Lima region. The work was executed with the strict adoption of COVID-19 prevention protocols.

The Fernandinho dam was part of Vale’s Dam Decharacterization Program, aimed at structures with upstream heightening, a method similar to that used for the Brumadinho dam, which collapsed in January 2019 and killed more than 250 people. The decharacterization of upstream dams is a commitment made by Vale and a legal obligation to increase the safety of communities and operations. The company has completely decharacterized six upstream structures and reintegrated them into the environment.

Completion of the Fábrica ECJ

The containment structure that was completed downstream from the Fábrica mine, known as Fábrica ECJ, has the capacity to retain the tailings of the Forquilhas I, II, III, IV and Grupo dams, located upstream of the Fábrica mine. The 95-m high and 330-m long structure has been designed to withstand the hypothetical scenario of the five dams rupturing simultaneously. In addition to improving safety for the people living in nearby communities, it protects the Secondary Safety Zones of the aforementioned dams, which include part of the municipalities of Itabirito, Raposos, Rio Acima and Nova Lima, in addition to three neighborhoods in Belo Horizonte.

With Fábrica ECJ completed, Vale can begin the process of decharacterization of the Forquilhas I, II, III, IV and Grupo dams. Forquilha IV dam is at emergency level 1, Forquilhas I, II and Grupo are at level 2, and Forquilhas III is at level 3 of the Emergency Action Plan for Mining Dams (PAEBM). All structures have continuous instrumented monitoring, 24 hours a day, seven days a week, managed by Vale’s Geotechnical Monitoring Center. Fábrica’s ECJ was built under the strictest national standards, the best engineering practices and technical references from international entities. Vale continues to assess, together with the technical auditor of the Public Prosecutor’s Office, the need for additional actions.

Vale said the completion of these two projects and the other advances of Vale’s Decharacterization Program represent its commitment to a more transparent and safer approach to managing tailings dams.

The Fernandinho decharacterization process involved removing 558,000 m3 of tailings and the installation of a central drainage channel.

Decharacterization Plan for B3/B4 and Sul Superior Dams

Vale also started activities with unmanned equipment for the removal of tailings from B3/B4 dam at the Mar Azul mine in Nova Lima and the Sul Superior dam at the Gongo Soco mine in Barão de Cocais. Both communities are in Minas Gerais. The company’s actions were assessed and approved by the public prosecutor’s technical auditor, in addition to the entire body of external consultants hired by the company to prepare the projects, and represent the progress of the company’s Decharacterization Program and the commitment to an approach fully focused on the safety of people and structures.

The decharacterization of these dams, which are currently at emergency level 3 of the PAEBM, is a complex process. Aware that any intervention may increase risks, the company has already carried out several preventive actions, including the removal of all residents from the respective Self-Rescue Zones (ZAS) and the construction of backup dams (downstream containment structures) in both territories.

At the Sul Superior dam, the removal will begin with the collection of samples, which aims to increase knowledge on the characteristics of the material disposed in the reservoir, to improve safety and the techniques that will be used in the decharacterization process, in addition to subsidizing studies to define vibration control levels. Channels will also be opened to improve the flow of water from the structure, preventing accumulation in the reservoir, especially during the rainy season.

At the B3/B4 dam, the tailings removal will be performed together with the completion of the partial removal of a waste pile present at the site, from which 350,000 m3 of material have already been removed since November 2020. All activities performed and planned for the two dams will be fully executed with unmanned equipment, operated remotely and safely from a control center outside the structures.

In view of the complexity and risks of the decharacterization process of these structures, Vale said it has strict control over all the actions implemented with the objective of ensuring the safety of workers and people living in nearby communities. In addition, the company is also studying additional measures to minimize any residual impacts on water bodies downstream of the backup dams.

Backup dams built downstream of the two dams are complete and have the capacity to contain the tailings if needed. The structure that serves Sul Superior dam is 36 m high and 330 m long. The structure that serves B3/B4 dam is 33 m high and 221 m long. These works also followed the strictest Brazilian standards, the best engineering practices and technical references from international entities used for similar constructions. Specialist companies, independent from the designer and the builder, assessed and certified that the backup dams are stable and, therefore, provide safety to the communities downstream. The technical auditor of the Public Prosecutor’s Office of Minas Gerais also ratified the stability of the backup dams.

As part of risk control, the dams continue to be permanently monitored by the Geotechnical Monitoring Center (CMG). If necessary, the activities will be suspended for appropriate evaluations. The actions have also followed all the protocols for the prevention to COVID-19.

Decharacterization Program

The 8B dam was the first of the five Vale dams that have been completely decharacterized and reintegrated into

the environment. The 8B dam, which is located at the Águas Claras mine, in Nova Lima, was followed by three structures in the state of Pará. The decharacterization of Dique Rio do Peixe, in Itabira in Minas Gerais, is also complete, as well as the previously mentioned Fernandinho dam.

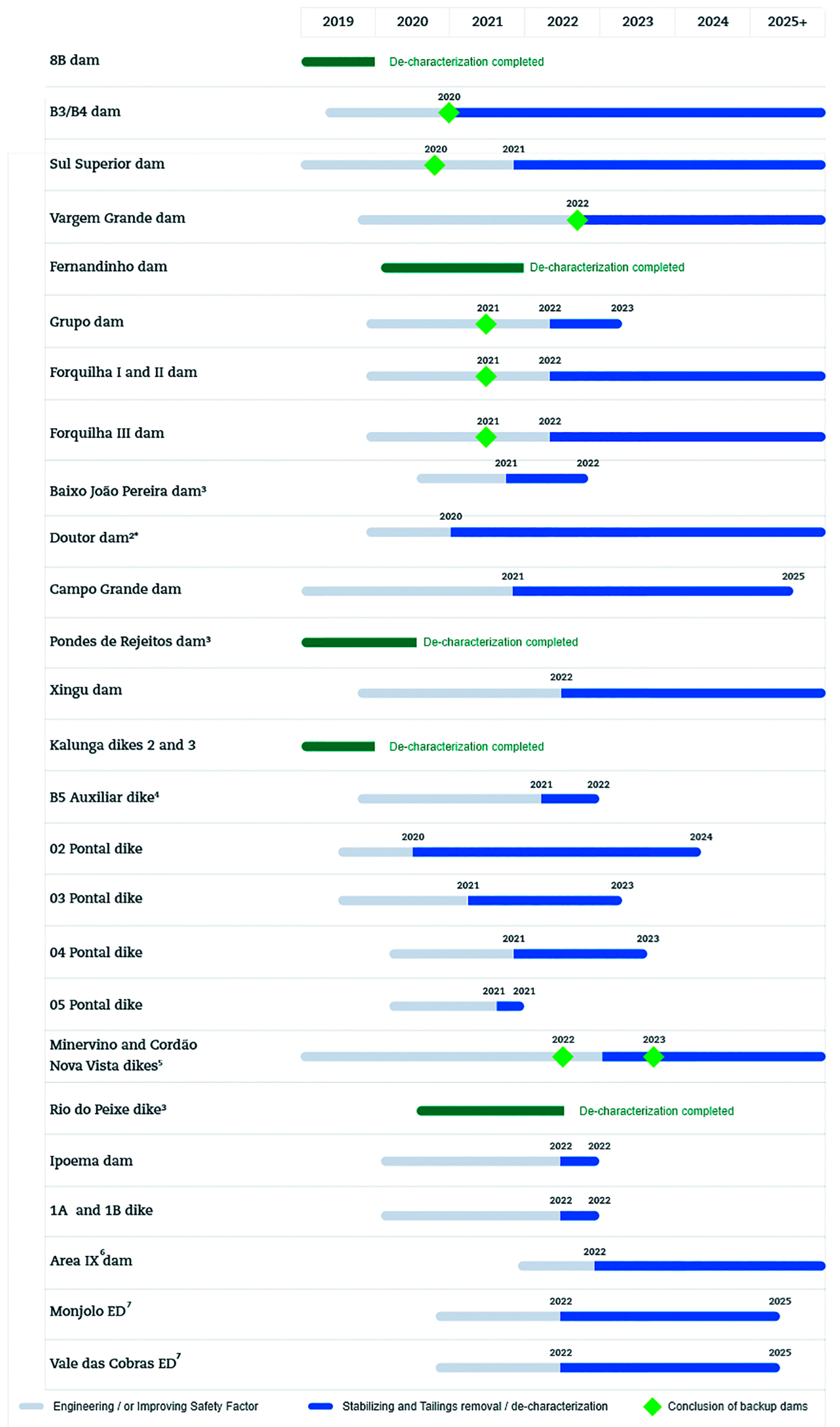

Vale’s Decharacterization Program for upstream dams is based on technical information and studies and considers the specificity of each of the 30 geotechnical structures, comprising 16 dams, 12 dikes and two drained piles.

The decharacterization of upstream dams is now a legal obligation of all mining companies in Brazil and Vale, committed to all, has executed all activities with the monitoring and support of external consultants, authorities and technical auditors of the authorities, always with the premise of safety of people and the environment. Each project, without distinction, is technically reviewed by more than one specialist, including the public prosecutor’s technical auditor. The timeline of the Decharacterization Program and other information on Vale’s dam management are available at www.vale.com/esg.

What is Decharacterization?

The term ‘‘decharacterization’’ means functionally reintegrating the structure and its contents into the environment, so that the structure no longer serves its primary purpose of acting as a tailings containment. Recently approved laws and regulations in Brazil require mining companies to decharacterize all of their upstream structures on a specified timetable, based on projects agreed with authorities.

The decharacterization of an upstream structure is a complex process and may take a long time to be concluded with the necessary safety precautions. The works related to the decharacterization process may influence the geotechnical stability conditions and increase the risk of such structures.

Vale is conducting detailed engineering studies for each structure to be decharacterized and the improvement of stability may be required, through reinforcement works or building downstream containment structures (ECJ or backup dam) to safely initiate the decharacterization. The backup dams have the purpose of retaining tailings in the event of a dam failure. All these projects are subject to further review and eventual approval by the authorities.