Progress was accelerating as the mining industry prepared to launch from a solid foundation built over the course of 100 years

By Steve Fiscor, Editor-in-Chief

Engineering & Mining Journal (E&MJ) celebrated its 100th birthday during June 1966. Alvin W. Knoerr was the editor at the time, a position he had held since 1955. He and his associates had chronicled the revolutionary advances that had taken place in exploration, mining and mineral processing during the roughly 20-year span following World War II.

The theme for E&MJ’s Centennial edition was Mining’s Dynamic Age. Rather than documenting 100 years of mining history, the editors opted to showcase the start-of-the-art in mining and mineral processing, contemplate the issues of the day and make meaningful forecasts about the future direction of the industry. That edition alone was 738 pages and 40-mm thick. While more than half of the magazine was advertisements, it was three times the thickness of the average E&MJ in the 1960s, which is twice as thick as E&MJ today.

Color was gradually beginning to creep into the magazine. The ads and articles that appeared in four-color were printed on a separate, heavier stock to prevent the colors from bleeding through the page. Most of the content was still black-and-white, but photography had improved substantially by this point. If there was artwork on the cover, it was usually an illustration rather than a photograph, a step backward in appearance from the 1930s and early 1940s. The mast in the 1950s had done away with the acronym E&MJ in favor of spelling the entire name in capital letters. In the 1960s, the publisher reverts back to the acronym with a slash

(E&MJ) rather than an ampersand.

Despite the physical appearance, the technical reporting was top notch. E/MJ served its readers a monthly helping of articles on mining and mineral processing technology, equipment, metals markets and a number of other subjects that mining engineers and metallurgists had to deal with at the time. The magazine also routinely covered stories from obscure parts of the world. More of the stories appear to be staff written rather than work contributed by readers. The mining industry was beginning to grow by leaps and bounds and E&MJ was asserting itself as the authority.

Alvin W. Knoerr, E&MJ editor, 1955-1971.

The 1950’s Renaissance

The industrial machine developed during World War II is winding down in the 1950s. The North American mining industry was dealing with the over-capacity this change brought about. Labor issues were prevalent. Mines that had been destroyed in the war-torn areas were being restored and capacity was building in Latin America and Africa. The Atomic Age had arrived and created a uranium boom. Companies that had previously confined their activities to railroading, chemicals, oil and gas, or construction industries were now participating in mining ventures on an unprecedented scale.

As an example, the mill at Bagdad Copper Corp. in Arizona was processing 100,000 tons per day of ore containing 1% copper. The open-pit mine was blasting ore from 50-ft benches using 7-in. blastholes. Trackless equipment was becoming prevalent underground. Continuous miners had become an accepted practice in underground coal and the miners were experimenting with the equipment in underground soft-rock applications. Roof and rock bolting were gaining wider recognition for supporting ground. Long-hole drilling operations underground were now using carbide bits and coupled rods. The Geiger counter was the latest exploration tool.

Another pattern was also beginning to emerge. Mining companies operating in foreign lands were strengthening their public relations programs. What is typically known today as corporate social responsibility was referred to as “industrial statesmanship” in the late 1950s. The object was to explain company policies and plans to “citizens,” overcome language barriers, and show how the mining enterprise benefits the individual, the community and the nation.

E&MJ’s editorial leadership changed hands three times in the 1950s; each of the editors were promoted internally and they had been writing for the magazine for years. Knoerr replaced Robert H. Ramsey who was editor from 1952 until 1955. Ramsey reported on the great mining developments following World War II and the ensuing expansion programs. His feature writing gave a real lift to mining journalism. Ramsey replaced Evan Just, who served as the E&MJ editor from 1945-1952. Just’s close association with leaders in industry and government contributed to the high-level perspective, which he infused in editorials and articles on industry problems and crises during World War II and later years. Knoerr referred to Just’s editorials and features to promote the status of young engineers as exemplary.

“We’re in a technological renaissance,” Knoerr wrote in a February 1957 piece titled Changing Patterns in Mining. “There was a time in the field of mining, milling, and smelting when technologic progress was slow and things remained relatively unchanged from year to year. But since World War II the rate of advance has accelerated tremendously. It’s safe to say that more progress has been made in the past 10 years than in the previous 50—and we’re only getting off to a good start. With the new electronic computers, modern research tools, brain-storming engineers, and bigger research budgets, the obsolescence rate of traditional technologic methods and processes is bound to be painfully high.”

The Centennial edition acknowledged the efforts of Knoerr and his associates and indicated that “as E/MJ entered its second century, communications will have to undergo modernization as drastic in character as the technical developments in the industry itself.

|

|

| Illustrations were common on the covers (May 1951). | E/MJ’s centennial edition (June 1960). |

Mining’s Dynamic Age

With an accelerating technical revolution under way and an intensifying evolution of a political world, within which mining would have to orient itself, the theme selected for the Centennial edition was Mining’s Dynamic Age as the editors chose to explore the challenges that lie ahead.

The Centennial edition opens with a four-color Miracle of Modern Mining section. “We have indulged in a little bit of justifiable bragging about an industry which we believe is not properly appreciated by either the public or in international political circles,” Knoerr wrote. Sound familiar? The mining business has been bearing this load for at least 50 years now.

The Miracle of Modern Mining section begins with a discussion of mineral exploration. Although the piece was written with the hopes of reaching a larger audience, it notes technical achievements, such as the electromagnetic peaks recorded on the tapes of an exploration helicopter flying over Timmins, Ontario. It revealed the presence of a rich copper-zinc-silver orebody, which was developed by the Texas Gulf Sulphur Co. Similarly, the article notes how Bethlehem Steel Co. discovered an iron orebody buried 1,500 ft below overburden in Pennsylvania using an airborne magnetometer survey. This discovery eventually led to the development of the Grace mine.

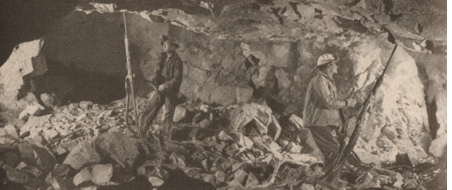

Two underground miners talk shop in the 1950s.

The Mining Section showcases some of the best of the best at the time, including the Viburnum mine and mill in Missouri, Bingham Canyon in Utah, and Toquepala in Peru. Another piece describes the evolution of underground mining in Butte, Montana. It also documents the history of iron ore and explains the importance of iron ore pellets with reports from the iron range in Minnesota; Canada’s Labrador region and Kiruna in Sweden. Several more articles cover Canada’s International Nickel Co. (Inco), Climax Moly, the uranium boom, oil sands in Alberta, and potash in Saskatchewan. Yes, many of these mines are still running today, 50 years later. Others wait to be reopened.

The world was making a similar, radical transition. This was the Age of Aquarius and the Beatles. Space exploration was becoming a reality. A tumultuous period of racial unrest was taking place in the U.S. with Martin Luther King Jr.’s assassination and in South Africa with Nelson Mandela’s arrest. And of course, the wars; The Bay of Pigs, Vietnam War, the Congo Crisis, Rhodesia, Angola, The Troubles, Colombian Revolution, etc. Over-population was also a major concern. How would the world provide for its people?

E/MJ at the time was bold enough to suggest Mining’s Conquest of the Earth. “It is pleasing popular to speculate on space and to spend billions on the conquest of it,” the E/MJ editors wrote. “But, the fact remains that millions here on Earth face starvation and hundreds of millions look hopefully for the development of lands and resources to raise them up out of abject poverty and a primitive way of living that is at least 1,000 years behind the times. The real conquest that must be made now is the conquest of the Earth.” This might be the first informal occurrence of: Earth First—We Will Mine the Other Planets Later. This level of hubris would not be acceptable today.

Their foresight for demand was impressive. “People, not population, with their compelling basic needs to survive, and the nuances of preference will impose the great and varied demands for metals and minerals. It is the awakening of people in developing nations that will account for: first, a self-sufficiency of food, and then, an unfolding of industrial development that will multiply world requirements for metals and minerals.

“It is the people who make the laws that will create the environment of the future. To grow within the bounds of these political and economic environments will be another challenge to mining—to lend its talent and counsel to the formulation of sound and equitable mineral policies will be one of mining’s greatest opportunities.” This passage was prescient as the U.S. Congress in a few years would pass the Mine Act, which would lead to the creation of the Mine Safety and Health Administration.

Kenecott’s Utah Copper tabulates the Bingham Canyon orebody with a computer.

Economies of Scale

Readers might be surprised to learn that E/MJ was discussing the lowest cost per ton more than 50 years ago. Most of the mining took place in open-pit operations and the scale-up in size of the equipment used for open-pit mining had been nothing short of phenomenal. The Utah Copper Division of Kennecott Copper Corp., during July 1965, reported that it had moved 403,426 tons of ore and waste in one 24-hour period.

Drilling and blasting had also improved. On the surface, miners now had the ability to drill a 15-in. hole. Slurry type blasting agents were replacing prill. Underground, short period delays (milliseconds) were available for initiators. Many operators now realized they can save money in downstream processes by investing in better fragmentation.

Computers were making an appearance. Kennecott discussed how it was using computers for mine planning. All of the survey information for the Bingham Canyon orebody was tabulated, key-punched and checked. E/MJ’s editors believed that eventually the entire spectrum of relevant mine information would be put in a computer.

To lend perspective as to how fast technology was moving, in the field of mineral processing E&MJ constantly reported on a slew of patents for solvent extraction, acid leaching, alkaline leaching, reduction by oxidation, chlorination, ion exchange and cyanidation. The mill superintendent in the 1960s was looking to reduce the number of process steps from the mine to the finished product. Similar to what was happening in the pits, the size and cost of crushing and grinding equipment was growing.

While they would be considered small by today’s standards, engineers in the 1960s were talking about “super-sized” flotation cells. The Booth Co. introduced a 225-ft3, 40-hp cell at an unnamed western U.S. copper porphyry operation. Approximately 3.5 times the size of conventional cells, it was referred to as the Hercules of flotation cells. Today, large flotation cells range from 300 m3 to as much as 600 m3.

“Despite the hazards of mining, there will always be men of courage and vision to push the industry ahead,” the E/MJ editors wrote. Reviewing the impressive progress the industry has made in the Centennial edition, they boast that “there seems to be ample evidence that the industry will be able to handle every kind of technical problem that will arise.”

Of all the challenges reviewed in the Centennial edition, the challenge of change appears to be the most demanding. “To ignore it with complacency will be equivalent to obsolescence and decay; to meet it, will require viability and ingenuity,” the E/MJ editors wrote. As E/MJ entered its second century of publication, it recognized that the challenge of change will be as important to mining communications, as it will be to the industry.

In concluding its first century of mining reporting, E/MJ offered its deepest gratitude to the thousands of members of the mining profession who helped make the pages useful and meaningful, and to the faithful correspondents in all parts of the world who have sent in myriads of reports that have profiled mining progress for a century.