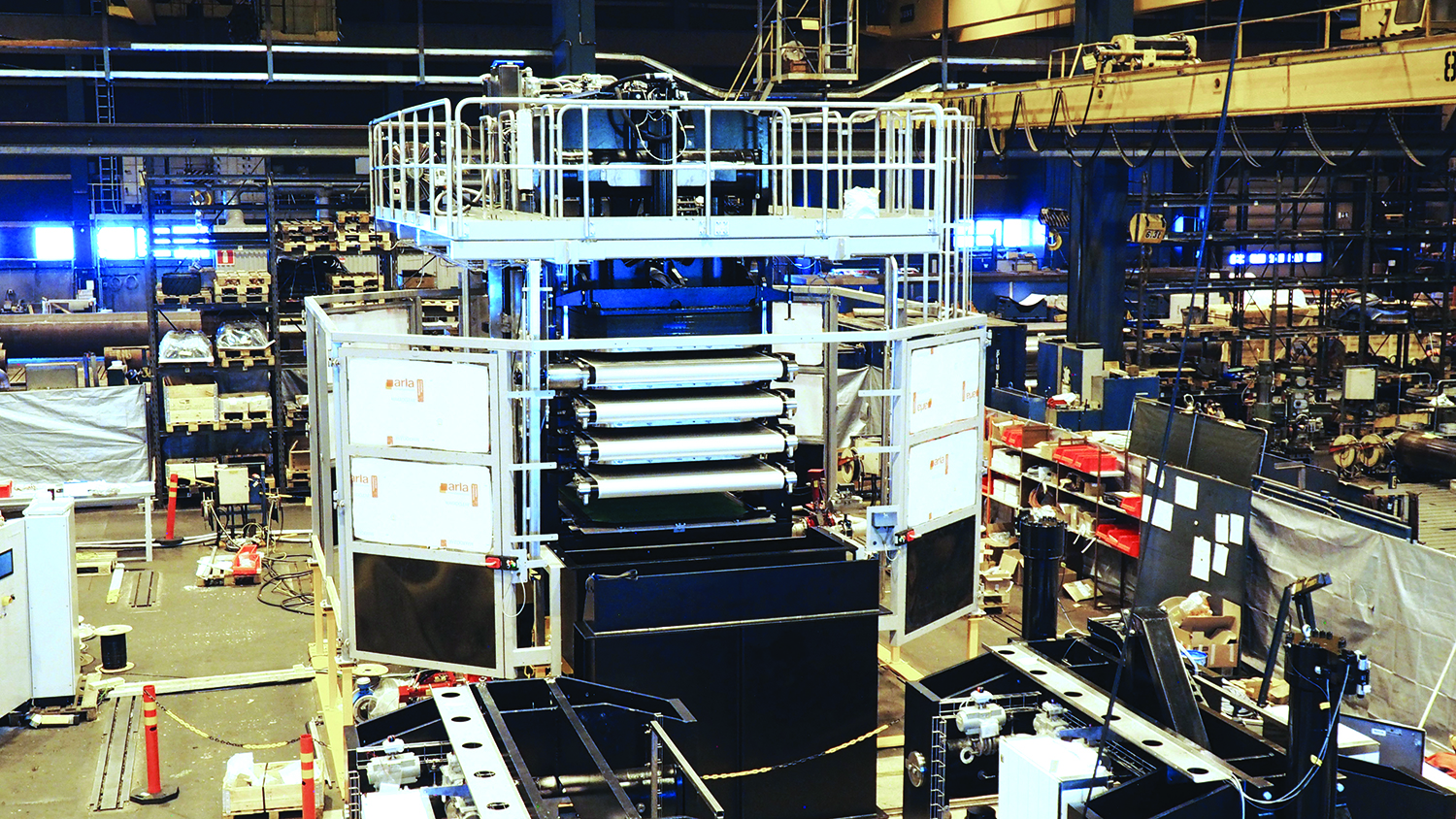

The GHT 5000-F Domino, above, is 1.5 times the size of a basketball court, and weighs 400 mt. (Photo: Diemme)

OEMs say their pressure filtration solutions can help miners comply with more rigorous standards for tailings disposal

By Jesse Morton, Technical Writer

On January 24, at an investor summit on mining hosted by the London Stock Exchange and held by the Church of England Pensions Board, the United Nations announced the Global Tailings Management Institute, “aimed at driving mining industry safety standards.” The institute will offer audits and certification for conformance to the Global Industry Standard on Tailings Management, published in 2020.

Requirement 3.2 of the Standard is “minimize the volume of tailings and water placed in external tailings facilities.” Thus, to committed activist investors, dry stack tailings may well be the only acceptable option. That will lead to increased demand for big pressure filtration systems that can handle the growing amount of waste rock slurry now being produced by mines facing lower grades.

The major OEMs say they have the solutions that can meet that demand.

To Dominate Tailings Management

Diemme Filtration said the company is building a GHT 5000F Domino for a copper mine in Chile. The gargantuan filter press is the second sold after one went to a Peruvian copper mine last year. “It will be ready by June,” said Andrea Pezzi, director, marketing and communication. “We will hopefully start this unit by the end of 2023.”

The unit will be trialed and once proven will likely be the first of as many as a dozen deployed to the site. The miner will use the filter presses to process waste rock slurry to dry cakes for stackable tailings. Pezzi said the sale is representative of the increasing demand for the Domino as a solution that cuts risk and helps mines meet increasingly strict water use regulations.

Increasingly, mines are prioritizing “water savings, risk mitigation, reduction of the footprint for the disposal of the tailings, and mine closure,” he said. “Their goals are a must for the industry and for us because I don’t think we are suppliers, we are partners for the industry.”

Currently, Diemme is seeing strong interest in the Domino, Pezzi said. “We are seeing inquiries from all the big names in mining,” he said. “For the top 20, with each of them, we have already a proposal or a discussion ongoing.”

One thing they are all talking about is “making a kind of change,” he said. “A change in their mentality, a change in their approach.”

One aspect of that is a different role for the supplier. “They decide to put skin in the game together with us in order to work as a kind of partnership,” Pezzi said. “In the past there was a different approach to where the relationship was more of a client asking for something from the vendor, and the vendor supplying something, and that was it,” he said. “Now both parties are more and more involved and the type of responsibility is shared in this type of project.”

The project type addresses the pressing issue of how to capture and reuse water from growing quantities of waste rock slurry. As ore grade declines worldwide, the amount of waste rock produced by mines is increasing. Meanwhile, increasingly governments are imposing stringent water use regulations on mines.

The two trends date back many years, and just over half decade ago Diemme committed to developing a solution that would in part answer them, said CEO Rosario Eduardo Tagliavini in November 2021 at the spectacular product launch event, which featured a live rock cover band and Hollywood actress Cynthia Gibb.

“There are currently several options for tailings management. But in some circumstances, for example with stable dry stacking or to recall as much water as possible, pressure filtration is still unrivaled,” he said. “The largest filters available on the market were not big enough for the huge amount of tailings that some mining operations produce each year.”

With Domino, Diemme sought to upsize the successful GHT-F overhead beam filter presses, resulting in “a real game changer in the filtration industry,” Tagliavini said. “The new machine maintains all of the features that have made the GHT series the most-referenced model of filter in tailings dewatering applications, with hundreds of installations on five continents.”

Except it is bigger by an order of magnitude. The Domino is 1.5 times the size of a basketball court, weighs 400 metric tons (mt), and the facility to house it will be the size of a 9-story building. The plates are 5 m x 5 m.

“We wanted to reduce the number of lines by increasing and developing a larger size,” Pezzi said. “And that is why we came to the 5- x 5-m model.”

The automated plate opening system unfurls “141 plates in one minute,” Pezzi said. “That is fast.”

Feeding and discharge holes are “sized to minimize abrasion and the downtime for maintenance,” Pezzi said. A catwalk and maintenance platform on top gives “easy access to all the parts,” he said. “You can do every operation from the top.”

For example, “from the top you will be able to do fast multiple-cloth replacements,” Pezzi said. “It is possible to change the media for multiple chambers at a time from both sides, quickly and safely.” Thus, the unit saves on capex “because you don’t need to build any additional floor around it.”

The automated low-pressure cloth washing system cleans “the whole cloth face simultaneously,” Pezzi said. The high-pressure cloth washing system, which clicks on after 20 or 30 cycles “for the strongest cleaning action, refreshes the filterability of the cloths.”

The 141 plates give a maximum achieved volume of “more than 71 m3,” he said. “In terms of filtration area, the total filtration area is around 2,850 m2.”

In one cycle, the Domino treats 151 mt of feed. It “can process up to 12,000 tpd of solids,” he said.

The unit in Peru, which hit some final testing milestones in December, will treat “more than 60 million mt per year of slurry,” Tagliavini said. “That is certainly an ambitious goal.”

Domino comes equipped with AIDA, a remote and automated machine monitoring solution. “AIDA is a service that we call a system tutor, where basically our company and our team is remotely connected with the site,” Pezzi said.

It enables “us as a supplier to monitor the performance, to collect data and history about the performance of the unit,” he said. “And for the client, this is a service where we are giving them the help and the support for the optimization of the unit as well as predictive and preventative maintenance.”

Using artificial intelligence, AIDA is expected to become more autonomous over time with the accumulation of data. “It is a kind of continuous improvement,” Pezzi said.

AIDA is easily accessed from a computer, smartphone or tablet. It connects with various platforms, including numerous apps. It offers analytics for decision-making, improved control, tracking and monitoring of cloths, support for predictive maintenance, and information that can be used to improve performance.

“The fact that we were the first in the world to develop a machine with these features is no coincidence since innovation is part of our mission,” Tagliavini said. “Digitalization of the GHT 5000 is the tangible expression of the Diemme spirit.”

The largest filter press in the world, it is dubbed Domino because “we want to dominate tailings management,” Pezzi said. “We are a company dedicated to finding the best approach and the best technology to meet the needs of the market.”

To help meet those needs, Diemme recently started construction that will expand its production facilities in Lugo, Italy, “in order to cope with the constant growth in demand for its innovative technologies,” the company said.

“We are replying to the market with investments in our facility to be ready to support more equipment and larger equipment,” Pezzi said. “We are getting ready for that.”

Improved Tower Press Design

Roxia reported the new TP16 tower press provides the best performance for the lowest cost per mt of concentrate, propelling the company into the top ranks of global suppliers for solid-liquid separation solutions. “Roxia is now a serious alternative as a technology provider after the introduction of the new Roxia TP16 and Roxia TP60 filters,” said Simo Manninen, vice president, business management.

The TP16 is a fully automatic pressure filter for any process that requires efficient solid-liquid separation, the company said. “Between it and the TP60, we offer filtration area from 16 m2 up to 168 m2, and production capacities from 4 mt/hour (h) to 90 mt/h,” he said.

Ideal for applications such as concentrate dewatering, the new TP16 offers efficiency and reliability improvements over predecessor solutions.

“Roxia’s focus was to improve the tower press design and we succeeded!” Manninen said. “There were more than 20 issues, both small and big, on our development list,” he said. “The main drivers were related to improved performance, ease of maintenance and improved safety.”

Operational performance improvements include faster cycles for greater production capacity, said Matti Luoma, commercial product manager, filters. The TP16 gives “more consistent operation even when feed slurry characteristics change,” he said. “It is designed to reduce filter cake buildup.”

Maintainability improvements include easier access to regular maintenance and inspection areas, he said. The unit features “high-quality consumable components,” Luoma said. Bigger units feature a moveable maintenance platform. “Safety perimeters provide more space for maintenance,” he said. There are “few service points in dirty areas.”

Safety improvements include structural design improvements preventing corrosion at critical areas, improved safety features, and well-planned operator and maintenance training, the company reported.

Key design improvements were to the hydraulic system, the filter cloth, and the filter frame.

“There are numerous details that set the Roxia TP aside from competitor solutions, but the most significant is related to the hydraulic system,” said Dan Stenglein, sales director, North America. “Tower presses have many subsystems such as the cloth drive, cloth tensioning, plate pack opening and closing, and so on,” he said. “These systems are operated by a hydraulic system. Because of the systems, the hydraulics wind up being complicated and specialized.”

The hydraulic system on the TP16, however, is comparatively simplified, which improves both the performance and reliability of the tower press.

“For example, we have reduced the number of hydraulic cylinders associated with filter plate operations from 14 to eight,” Stenglein said. “Also relocating these cylinders to the top of the unit was strategic to move them outside the process area where they would otherwise be subject to corrosion, dirt and other issues,” he said. “Our hydraulic system design also reduced the typical system volume of the hydraulic fluid, centralized and simplified needed controls such as directional valves, and allowed smartly routed hard piping with minimal hoses.”

A full platform atop the unit offers access to the hydraulics system.

A TP60 tower press has a production capacity of 90 mt/h and is designed to reduce cake buildup. Above, a TP60 at the Karhula facility. (Photo: Roxia)

Locating the hydraulics system above the process area means the filter plates are accessed from the floor level. “With the plate pack lower to the floor level, inspection and replacement is much easier and safer,” Stenglein said.

The plates are oriented horizontally and stacked vertically. “The plates, when sealed, provide a horizontal filtration chamber with no interferences or obstructions within,” he said.

The arrangement gives high throughput capacity and a small machine footprint.

“The horizontal chamber provides even filling and dewatering of the slurry resulting in a very uniform filter cake,” Stenglein said. “Further, subsequent process steps such as membrane squeezing, cake drying and, optionally, cake washing, are very effective and efficient in the horizontal chamber.”

The continuous filter cloth serpentines through the plates to provide the filtration surface at the base of each filtration chamber. “The filter cloth is connected by a seam at its ends to provide an endless loop,” Luoma said.

“After the process cycle, the filter opens the plate stack in an accordion fashion and the filter cloth then becomes a conveyor belt, discharging the filter cakes on both sides of the filter,” he said. “The cloth exiting the plate stack is continuously washed with high-pressure water, and then re-enters the plate pack.”

Washing the cloth after each cycle improves cloth efficiency and longevity. “The washing system is easier to access and maintain so it can operate reliably,” Luoma said. “Following the cloth wash, Roxia has improved cloth tensioning and tracking systems to ensure better functionality of both.”

Above, a Diefenbach filter press operates at three cycles per hour and processes 70 mt/d, Diefenbach reported. (Photo: Diefenbach)

The unit features a filter frame that is more resistant to corrosion than predecessor solutions.

“The redesigned frame provides for quicker installation and assembly, improved structural rigidity and support, increased corrosion tolerances, and a reduction of machine-finished surfaces,” Stenglein said.

The TP16 comes standard with the Roxia Malibu digital machine monitoring and reporting solution. “Access is possible anytime and anywhere with any computer, smartphone or other handheld device connected to the internet,” he said. “Data analysis can be used for comparing productivity, quality changes, energy consumption, production output, to determine reasons for its waiting time and alarms.”

The features allow the tower press to produce the driest filter cake possible using less energy and water, the company reported. “Roxia TP represents a competitive system providing the lowest cost per mt of concentrate and maximized production,” Luoma said.

It also offers the “lowest cost of ownership,” he said. “The Roxia TP is a smart design that reduces wear and tear,” Luoma said. “Locating the hydraulics to the top will result in fewer issues with corrosion, damage and interferences to componentry.”

The new release is the culmination of a long, meticulous development process practiced by a company with decades of experience, Manninen said. “Roxia is not a new company, but a new name!” he said. “We rebranded Flowrox after divesting our pump and valve business, and centered our focus on solid-liquid separation and related services.”

The larger TP60 launched in May of 2019. It was the result of a continuous improvement process that drew from Roxia experts and engineers from all over the world.

“Reviews were done by Roxia senior maintenance specialists,” Manninen said. “Their contribution can be seen in improved access to different service points at a filter,” he said. Roxia engineers produced numerous iterations of systems and layouts before arriving at final designs for the TP60. “This was a process that took 18 months.”

The TP16, which incorporated many of the design details of the TP60, was released December 16, 2022.

Roxia supplies auxiliary equipment, such as tanks and pumps, air and water supply solutions, and conveyors. “All these must be carefully selected and sized appropriately to maximize filter performance,” Manninen said. “Roxia is happy to support customers in this work and can also provide the complete solution on turnkey basis should that be customer’s preference.”

Eliminating Tailings Dams

McLanahan reported its filter presses can eliminate the need for slurry ponds and tailings dams. “McLanahan Filter Presses provide customers with proven technology that is capable of producing a drip-free cake,” said Dennis Zink, global product manager.

“The Filter Press also provides the ability to optimize the recovery of clean, reusable water,” he said. “McLanahan Filter Presses can address many typical issues associated with fine material processing, including full slurry ponds and dams, high material handling equipment repair costs, limited expansion capabilities, environmental permit restrictions, high waste material handling costs and limited water availability.”

McLanahan makes overhead beam and side beam units.

Overhead beam plates are available in sizes from 630 by 630 mm to 2 by 2 m. “Larger plate sizes are available upon customer requests,” company literature said.

The cake can be discharged either externally or internally. “Open discharge from each plate allows the operator to quickly and easily identify bad filter cloths, while internal return is used to prevent filtrate from being exposed to an open environment,” McLanahan said.

Compared to the Side Beam Filter Press, the Overhead Beam Filter Press has a bigger opening for better cake release. It also provides “better cleaning and maintenance access,” Zink said.

“McLanahan’s Overhead Beam style results in faster opening and closing for greater production in tailings applications,” he said. “McLanahan’s Side Beam unit is designed for concentrates and smaller tailings applications while providing fast plate and cloth removal.”

It can be transported “for modular or portable applications,” he said.

Plate sizes available for the Side Beam Filter Press range from 630 mm to 1.5 m.

Side Beam Filter Presses feature a plate-shaking system to release the cakes, options for the washing system, and a single hydraulic ram for quick plate opening. “This results in robust and reliable automation capabilities with lower horsepower, fewer control valves and less complexity than multi-cylinder designs,” Zink said.

McLanahan offers recessed chamber-style plates, and membrane filter plates.

Membrane plates offer higher production rates for compressible slurries or slurries that require a cake wash or cake blow, and produce “the driest cakes,” company literature said. “Cake thickness can range from 15 mm all the way up to 50 mm to suit a wide variety of slurries.”

McLanahan Membrane Plates can deliver a pressure of up to 15 bar.

The recessed chamber-style plates “offer flexibility with a wide range of cake thicknesses and limited maintenance,” McLanahan said. “To ensure highly efficient and productive operation, recessed chamber filter plates have no moving parts, resulting in longer plate life and easier operation.”

McLanahan Recessed Chamber Plates can deliver cake ranging in thickness from 15 mm to 50 mm. Feed pressure can range from 7 to 15 bar.

McLanahan Filter Presses use fewer chemicals than belt presses, and feature the Smart Hydraulic System for online monitoring and assistance. The system controls “operating pressure and mobile plate position for fast, precise opening and closing,” company literature said.

“The system can be designed for higher slurry feed pressure to meet specific application requirements,” McLanahan said. “The McLanahan Smart Hydraulic System is monitored and controlled via the standard Allen Bradley PLC or a customer-preferred control system with remote capabilities and assistance via Ethernet.”

The system features redundant hydraulic pressure relief valves that are tamper-proof and adjustable.

McLanahan Filter Presses are designed to specific customer needs. “The Filter Press is also designed for the specific application by selecting the cycle times, cake thickness, feed pressures and plate styles to achieve optimum dewatering efficiencies,” Zink said.

Other listed possible benefits include “maximum water recovery, easily managed solid waste material, reduced waste handling cost, reduced material handling equipment cost, and service and support from a world-renowned company,” he said.

McLanahan has delivered more than 55 filter press systems globally in the past 10 years. “Our equipment is built in-house at McLanahan in the U.S.A.,” Zink said. “Every filter press is tailored to the customer’s requirements, and is backed by our support services before, during, and after project delivery.”

McLanahan Overhead Beam Filter Press plates are available in sizes from 630 x 630 mm to 2 x 2 m. Above, two units dewater coal tailings. (Photo: McLanahan)

Guaranteed Synchronization, Perfect Load Distribution

Diefenbach reported its one-cylinder design gives a superior performance over competitor overhead beam and side beam filter presses.

“We use only one cylinder to close the plate pack,” said Matteo Codeghini, sales engineer. “Other competitors use more than one cylinder,” he said. “This can be problematic because there is a possibility of unequal load distribution, inaccurate plate closure and the possibility of loss of sync.”

That can lead to structural deformation and decreased plate life.

In contrast the one-cylinder design “guarantees” synchronization “so It does not promote unexpected structural stresses on both the main structure and the plates,” he said. “Our filter press, thanks in part to a designed mobile head, has perfect load distribution.”

Diefenbach filter presses “consist of two fixed heads, an overhead beam or two side beams, and a moving head containing a pack of vertical plates,” Codeghini said. “Each filter plate is dressed with a filter cloth on both sides and, once pressed together, they form a series of chambers whose number depends on the plate number,” he said. “The sludge can pass through the plate pack by a feeding pump.”

The units offer high capacity and allow for the installation of up to 180 2.5-by-2.5-m plates that give a filtration pressure of more than 16 bars. They can produce up to 200 mt/h of dehydrated product, or up to 35 m3 of discharged product each cycle.

The units are designed to be “sturdier than competitor models, allowing for greater durability over the years,” Codeghini said. “We have filter presses still working after 30 years.”

Diefenbach filter presses feature high-quality components for “excellent performance and safety over the years,” he said. And, each unit can be customized.

“We offer the possibility to vary technology according to customer needs and sludge type,” Codeghini said. “Diefenbach offers filter presses designed to match the duty required by the application,” he said. “Diefenbach filter presses can feature specialized coatings for protection against corrosion and highly acidic sludges, and they can be engineered to meet ATEX certification for use in hazardous environments.”

The company offers on-site and remote support. “Our filter press is fully automatic,” Codeghini said. “There is only a need for supervision of the worker,” he said. “And also, because with our HMI, we can connect remotely with the machine, helping the customer solve any problems.”

Founded in 1907 in northern Italy, Diefenbach initially designed solutions for the olive oil industry.

“In the 1950s, the company focused production exclusively on the filter presses, able to filtrate oils and purify the industrial wastewater,” Codeghini said. It expanded into the mining space in 1970. “Diefenbach has been able to develop a know-how to allow itself to now produce over 50 machines per year that operate in all the fields where the filtration is necessary.”