Understanding wearing performance of the haul road’s surface allows engineers to make better design and construction decisions

By Dr. Roger J. Thompson

Predicting long-term haul road performance is integral to both conventional and autonomous haulage — but in many operations, the road maintenance — road performance relationship is not well understood. Functional failure of a haul road is inevitable due to the combined effects of climate, traffic and importantly, the quality of the build. But when does that failure occur? Will a road require a significant investment in resheeting — replacing the wearing course or running surface — during its operating life? As these interventions will be both costly and disruptive, ideally a road design should be matched as closely as possible to its duty in terms of life and tonnage hauled.

Mines can develop a more mature understanding of the road sheeting or wearing course performance over the short- and long-term, to support design and construction decision making allied to the haulage task assigned to the road.

Haul-road maintenance management encompasses many activities associated with the asset itself from the road surface to roadside drainage, safety berms, signage, spillage removal, etc. More commonly nowadays, browser-based data road condition visualization systems using various data sources — fleet management systems, truck on-board, geotagged inspections and road recordings, etc. — enable a mine to better integrate road maintenance decision-making into their overall workflow management systems. While this approach helps in recognizing poorly performing segments in the network, it doesn’t offer any insight into the root-cause of the underperformance. Efficient, targeted road maintenance also requires interventions that address the fundamental cause of the failure, otherwise the problem will reemerge again as soon as the road is reopened to traffic.

In terms of the surface or wearing course “functionality” itself, maintenance management can be split into two main activities:

• short-term “routine” or patrol maintenance – routine interventions over a typical maintenance cycle of 10- to 21-day intervals, during which time minor surface deterioration increases rolling resistance and reduces “functionality,” until maintenance restores them close to the original or design performance levels; and

• longer-term wearing course restoration or resheeting campaigns, triggered by accumulated deterioration as a result of repeated routine maintenance activities, together with traffic and environmental breakdown, to the point where the wearing course would require deep reworking (to expose fresh material — typical of a roads campaign), or eventually, total replacement (typical of a road rehabilitation campaign).

Any road design must incorporate consideration of the structural design or layerworks — primarily to carry the imposed wheel loads and traffic volumes over the design life of the road. Structural design is what determines the overall life of the road and shouldn’t figure significantly in short- or longer-term maintenance activities. Structural failures of a road are expensive, disruptive and time-consuming to repair. A mechanistic structural design methodology delivers a structural design according to life, traffic volumes and level of service required and conversely, operating life can also be estimated for a road structure as built and trafficked.

This would be the starting point for any longer-term wearing course restoration or resheeting campaign — does the structure of the road offer enough “life” to cater for the anticipated life of the refurbished sheeting? A prerequisite for any investment in a resheeting campaign is a sound and satisfactory structural design. Assuming this imperative is met, how then is maintenance managed in the short- and longer-term?

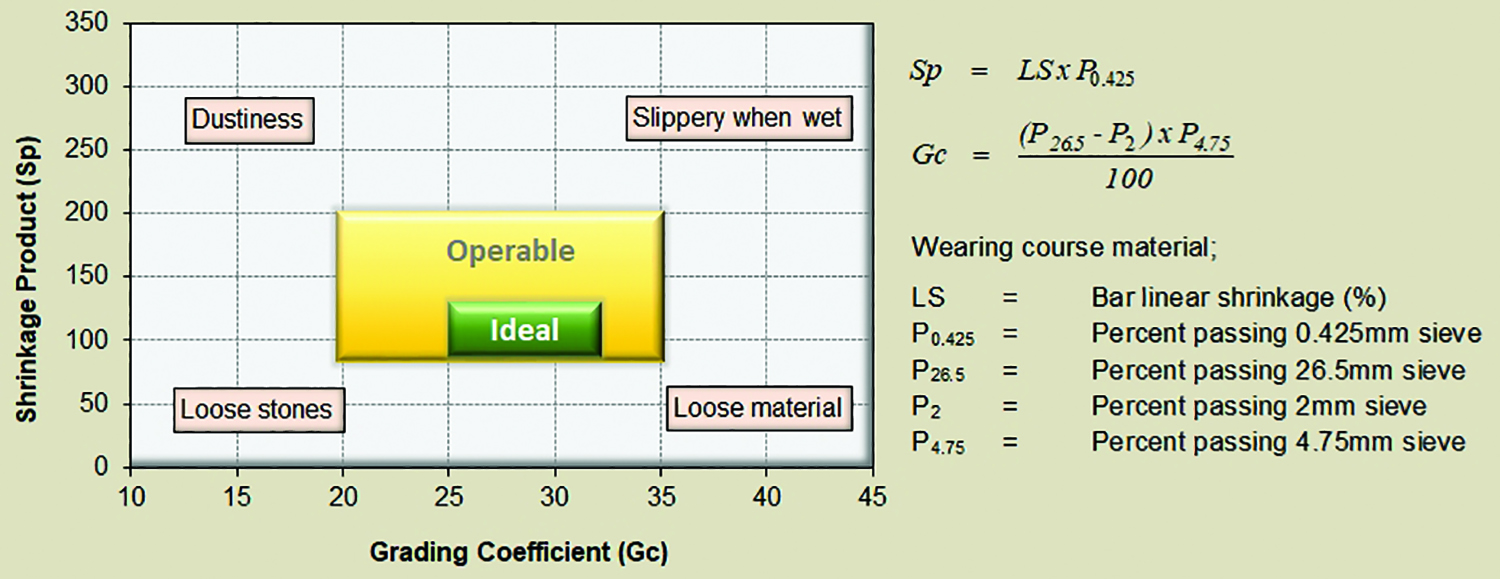

Figure 1—Selection parameters for a mine haul road wearing course material.

Selecting Wearing Course

The haul road wearing course material or sheeting exercises a significant influence over the required maintenance interventions. The functional design of a haul road is the process of selecting the most appropriate wearing course (or sheeting) material or mix of materials commensurate with safety, operational, environmental and economic considerations. Selection is thus broader than just considerations of rolling resistance progression but nevertheless, a well selected wearing course material (or blend of materials) will exhibit greatest endurance to deterioration.

Typically natural gravel or crushed stone and gravel mixtures have, in addition to their low rolling resistance and high coefficient of adhesion, advantages over other wearing course materials in those road surfaces can be constructed rapidly and maintained at relatively low cost. If mine waste materials can be used for construction, the costs are all the more favorable. This cost advantage is, however, not apparent in the long term if the characteristics of the wearing course material result in sub-optimal short- and long-term performance. Figure 1 shows the recommended selection ranges for the two key parameters of Shrinkage Product (Sp) and Grading Coefficient (Gc), used as a guide to wearing course material suitability.

To assess the suitability of a potential wearing course, a civil laboratory will conduct the following sample material tests from which the parameters in Figure 1 can be determined:

• Particle Size Distribution of 75 mm to 75 microns (µm);

• Atterberg Limits PL, LL, PI and linear shrinkage;

• Maximum Modified Dry Density (Mod MDD); and

• California Bearing Ratio (CBR) at 100% Mod MDD (no soak or four-day soak depending on climate).

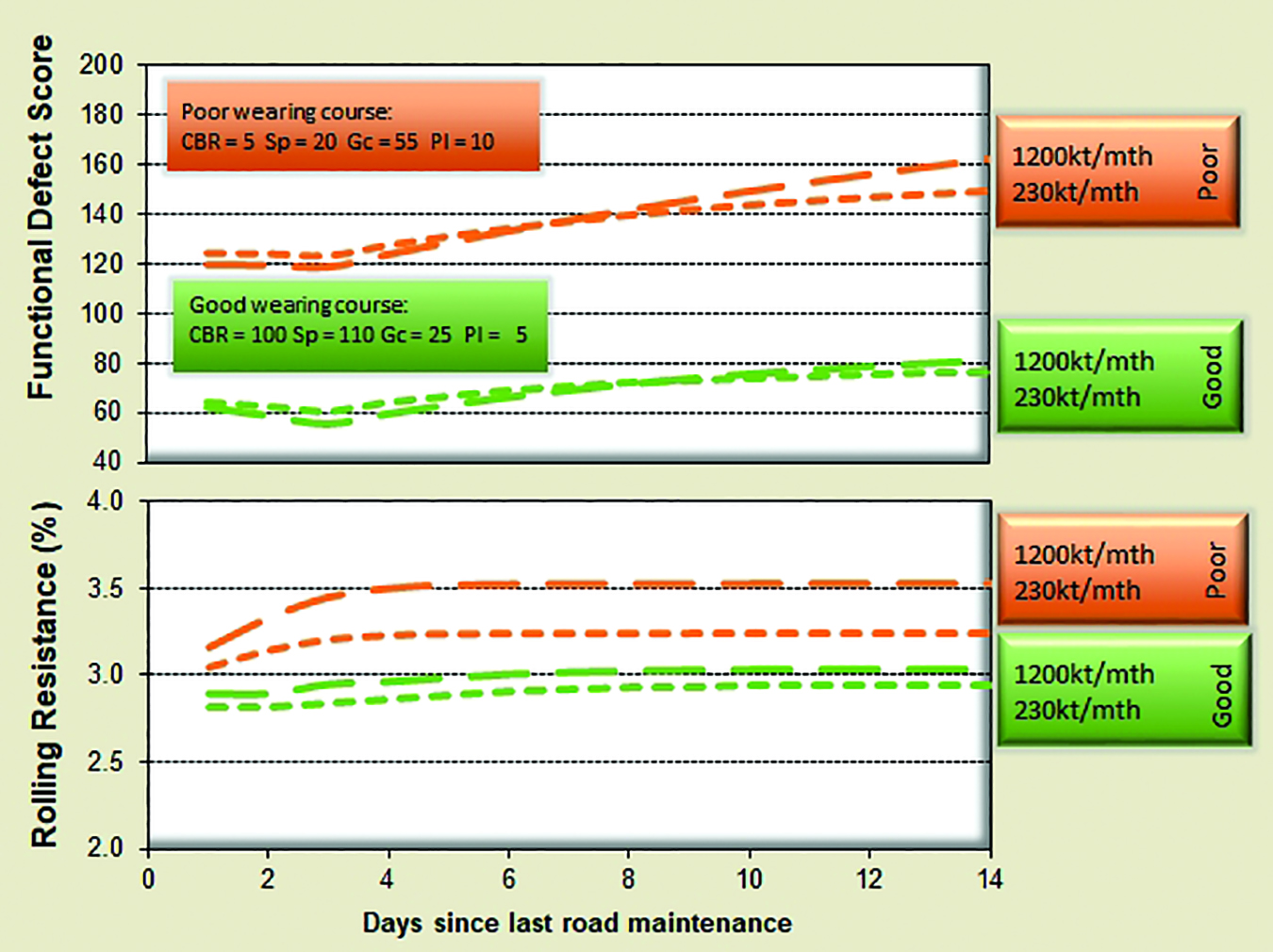

Figure 2—Impact of well- and poorly selected wearing course on road functionality and rolling resistance.

Routine Road Maintenance

Short-term (routine) haul road surface maintenance requirements are well understood and described1. Deterioration over a maintenance cycle can be established readily by considering the wearing course parameters described together with the traffic volume the road carries. As traffic volume increases, so does the functional deterioration and rolling resistance. Critically, the rate of deterioration can be controlled and minimized by the judicious choice of wearing course material.

Figure 2 illustrates how a wearing course will deteriorate in terms of:

• its function (measured on the basis of a “defect score” representing the 11 key defects influencing road condition, where a score 200 or more represents a severely distressed road); and

• its rolling resistance, where a typical benchmark for a well-selected and managed wearing course is 2%-2.5%.

Figure 2 also shows how a combination of poor wearing course material and high traffic volumes contribute to poor functionality, high rolling resistance and thus, very frequent road maintenance interventions, in an attempt to restore the surface condition. Although a reduction in rolling resistance from 3.5% to 3% appears small in absolute terms, this reduction for a 400-ton-class haul truck will see speed increase by 16% and fuel burn reduce by 11% (laden flat-haul).

Short term or routine road maintenance also recognizes that each road segment in the mine’s network of roads has an optimal maintenance frequency and minimum total cost. This is determined by considering the cost of road maintenance weighed against the losses incurred due to rolling resistance increase (generally in the form of increased fuel burn and slower cycle times). Roads that carry smaller daily tonnages would deteriorate more slowly in the first instance, and when coupled with the lower truck performance cost-penalties, it is these roads that would forego maintenance in preference to the higher tonnage more cost-sensitive segments of the network. This approach is useful where road maintenance assets are scarce and routine maintenance priorities need to be established to get the best value from each road maintenance dollar spent.

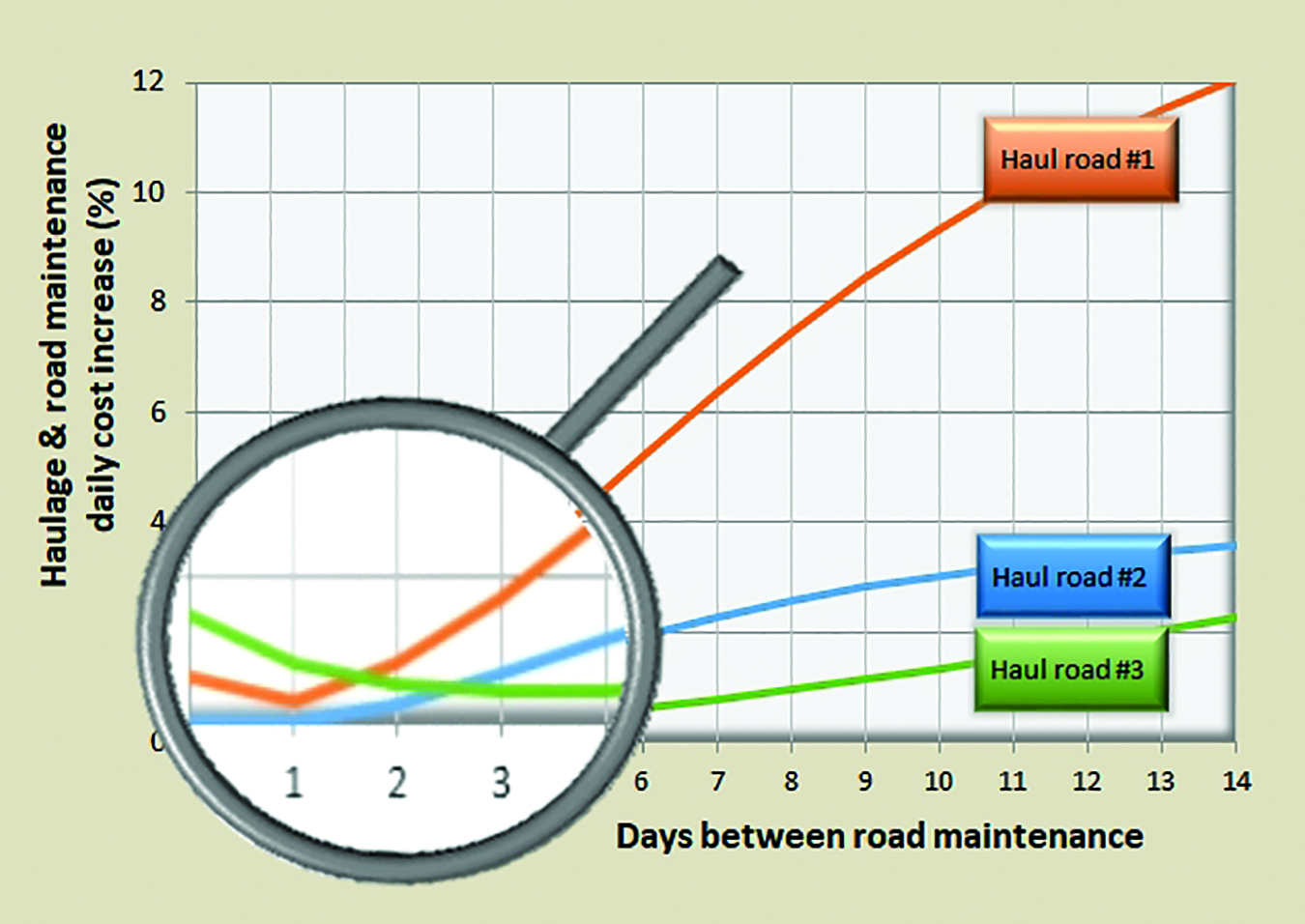

Figure 3 illustrates a typical result from a short-term road maintenance analysis. In this case segment, HR1 is most sensitive to effects of deterioration and routine maintenance is required every second day if costs on this segment are to be minimized. Costs of operating on segments HR2 and HR3 are much less as is the rate of increase in costs due to deterioration. Note that this type of analysis also gives us a useful insight into what maintenance interval is best suited to each road — where the cost curve reaches a minimum. In addition to cost blowouts associated with too little maintenance, it is possible to “over-maintain” a road where the investment in road maintenance is not recouped since truck haulage costs are not significantly reduced.

Figure 3—Short-term road maintenance analysis to identify segments of the road network most sensitive to deterioration.

Long-term Wearing Course Restoration

While the short-term approach to road maintenance manages the day-to-day operational optimization of road performance, it does not consider the longer-term traffic, environmental and maintenance-induced deterioration of the wearing course to the point where no amount of road maintenance will “fix” the road. At this point, the wearing course has declined to such an extent that it is significantly out of spec and the only solutions are extensive and potentially disruptive campaigns to either:

• rip and remix the wearing course — typically only the upper 50 mm of the material is impacted by short-term maintenance, so by deep ripping to the depth of the layer, remixing, watering, recompacting and shaping, the useful life of the layer can be extended; or

• replace or supplement the layer with fresh in-spec material. If supplementation is used, it will be necessary to bond the new layer to the original wearing course by lightly scarifying the latter.

Both options will restore the wearing course close to the original specification and level of performance. But, when will this become necessary and can it be anticipated and catered for in mine planning? These long-term performance questions can’t be answered easily with existing models of wearing course deterioration, since there are many site-specific variables that impact the solution. The answer is to develop long-term wearing course predictions based on the history of site roads that cover the key variables controlling performance.

Predicting Long-term Road Performance

As there are no generic haul road deterioration models to refer to, a site-specific empirical approach is required to capture the unique operating, wearing course materials and production characteristics at each site. In the majority of cases, modelling long-term deterioration is also based on sampling and assessing the wearing course Gc and Sp over at least one year of operations, together with additional data relating to:

• Days and dates (season) between assessments;

• Number of short-term maintenance (patrol grading) interventions between assessments;

• Dates (season) of any rip and remix or adding fresh wearing course;

• Traffic volumes (average kt/day between assessments) (impacts deterioration rates);

• Cumulative and average monthly site or road rainfall (wet periods impact deterioration);

• Predominant type(s) of material hauled (tracking and spillage of weathered material can significantly affect wearing course characteristics); and

• Ramp or flat-haul roads (different rates of deterioration).

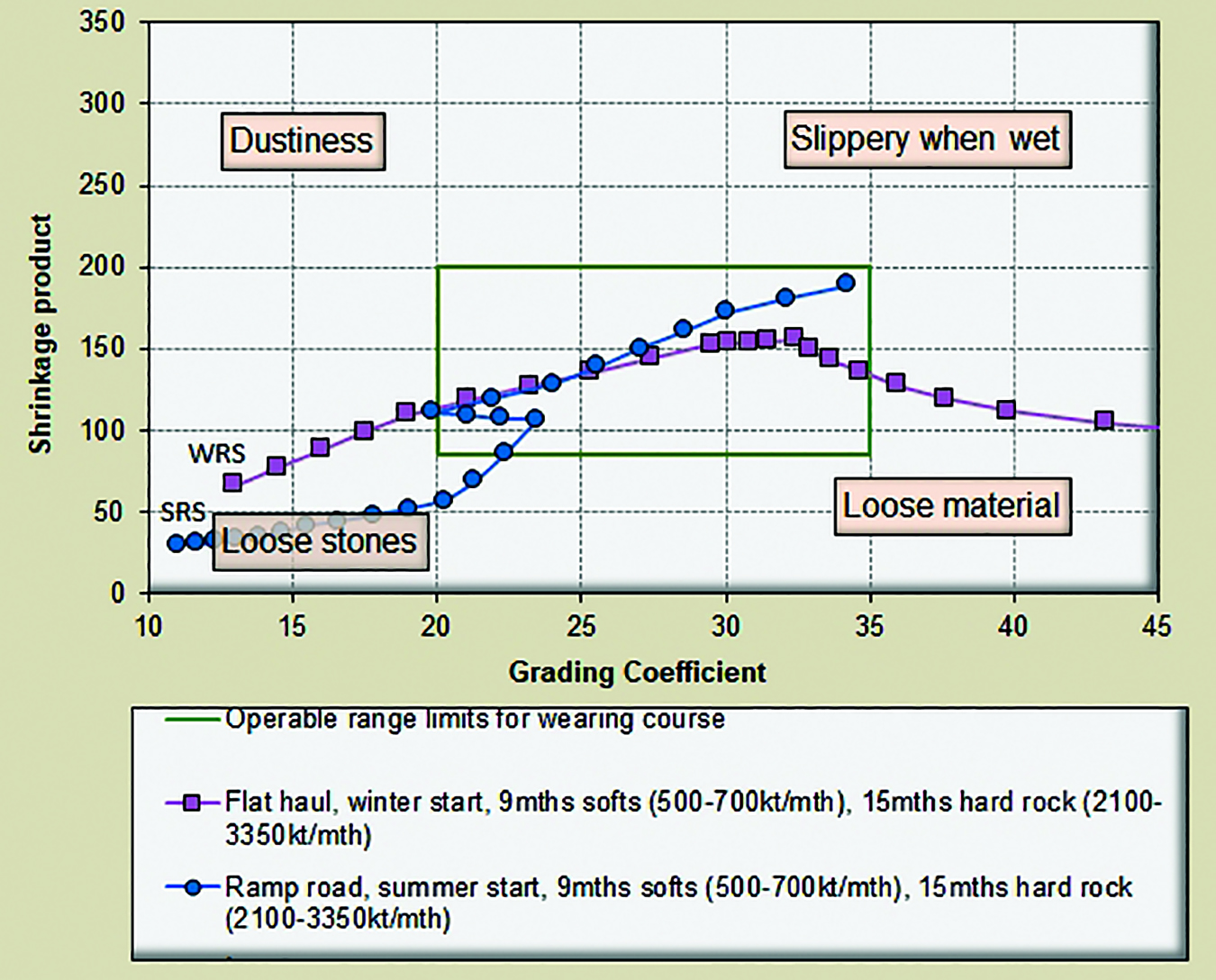

Figure 4—Wearing course degradation models for a specific mine site.

In the example discussed below, rainfall can be defined by two seasons (dry summer or wet winter), and the materials hauled are limited to hard and soft only. Typical performance models would cover:

• Rip & remix or resheet wearing course in:

–Winter (RS-W)

–Summer (RS-S)

• Road type:

–Ramp operations

• Summer “start” (i.e., when road first opened to traffic) (RO-S)

• Winter start (RO-W):

–Flat-haul operations

• Summer start (FO-S)

• Winter start (FO-W)

• Material hauled

–Hard waste/ore (base case for all models)

–Soft waste/ore summer ops (OX-S) or winter ops (OX-W).

Each characteristic model can be applied at any point in time (or tonnage hauled) so they combine to predict the deterioration of a particular road based on history of road (date of build or resheet/rip-and-remix and material Gc and Sp), together with planned monthly tonnages to be hauled, material types and ramp or flat-haul road configurations.

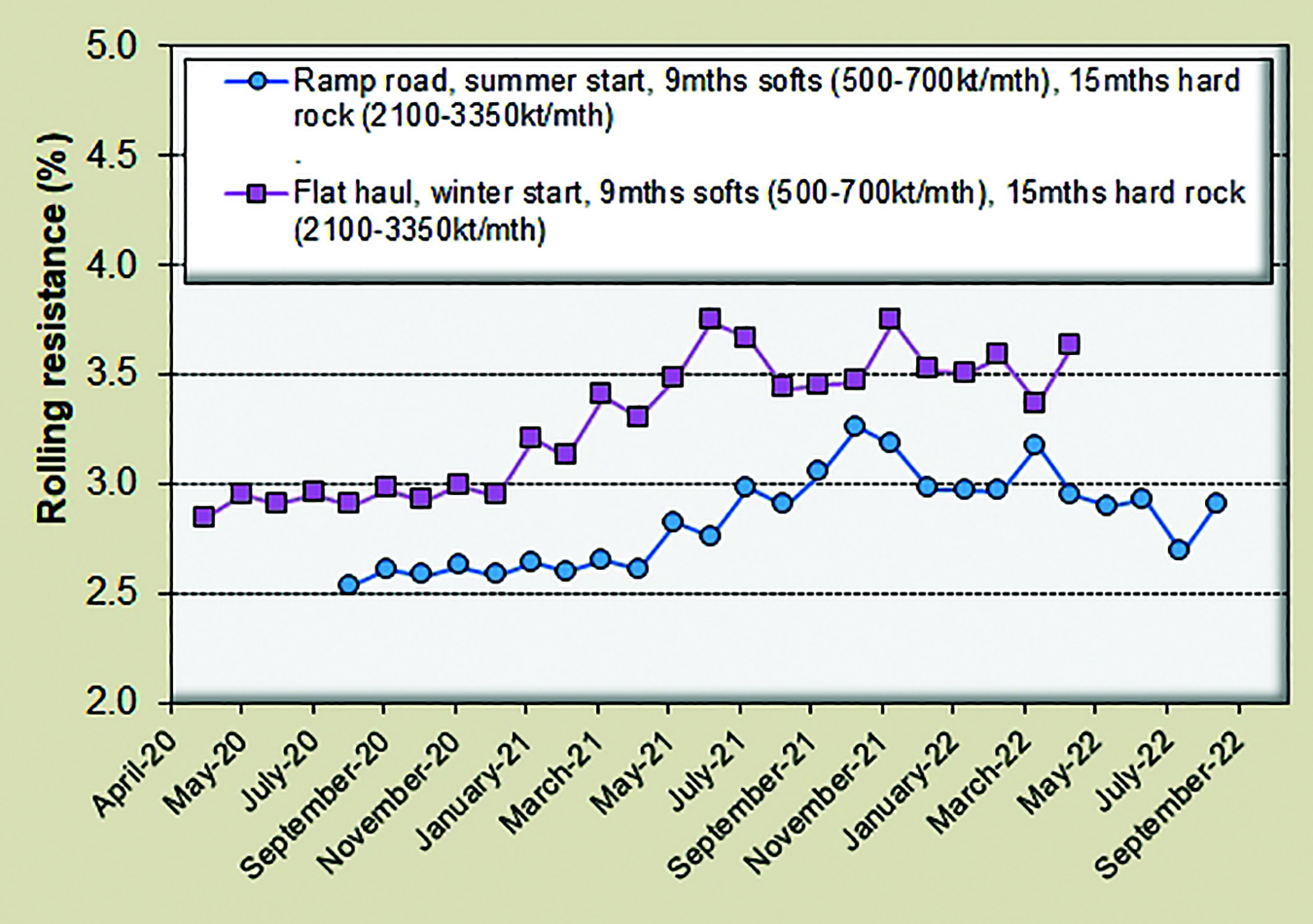

Figure 5—Two examples of long-term wearing course modelling results.

Figure 4 shows each of the long-term deterioration models (from an arbitrary start condition). The direction of the deterioration progression depends on the characteristics of the wearing course; crushed gravels tend to show an increasing Gc value when breaking down, whereas natural materials also show increasing Sp values. Spillage (especially fines), grade of road, climate (especially rain-induced surface erosion) all combine to further impact the mode of degradation.

When applying the method to an operation, Figure 5 shows two cases based an initial nine-months hauling soft rock at 500,000-700,000 metric tons per month (mt/m), following which hard rock is hauled for 15 months at between 2.1 to 3.35 million mt/m:

• In the first application, the road is a flat haul with a winter resheet. After approximately 18 months, the material Gc is out of spec and may trigger a resheet.

However, if the monthly tonnages and material remain similar for the following few months, functionality of the wearing course may still be adequate — albeit with more loose surface material (potential traction or friction supply issues) and a slight increase in rolling resistance (Figure 6).

• In the second application, a summer resheet and start is used on a ramp road, with the same rock types and tonnage schedule. The wearing course will be out of spec after 24 months, but in this case the issue would be a higher than desirable Sp value and associated wet trafficability issues. Interestingly in this case, the mine has elected to use a very “boney” (low plasticity and fines) wearing course for the resheet in recognition of the fact that as the road is trafficked, Sp increases. In that way, they can extract maximum service from the road with only minor disadvantages initially due to the stoney nature of the surface.

Fig6-min

The long-term change in rolling resistance shown in Figure 6 confirms the response of the road as traffic volume increases and/or as vehicle speed increases, the results reflecting the fundamental concepts of rolling resistance increase as a result of wearing course deterioration, together with speed- and traffic-induced accelerated damage to the road surface.

From a haulage-economics perspective, as both deterioration and rolling resistance increases, the impact on productivity and costs can be determined and a value assigned to the opportunity cost, such that a point in time can be determined when it is most cost-efficient to resheet the road. However, economics alone should not be the sole determinant of a roads campaign and consideration of road functionality will always be an equally important consideration.

Roger Thompson is the principal consultant at Mineravia, a niche consultancy specifically geared toward haul road design, construction and maintenance for mining operations.