Mines are seeing higher productivity and lower operating costs with automation.

Mines are seeing higher productivity and lower operating costs with automation.Exporting Nordic know-how to mines and mills around the world

By Steve Fiscor, Editor-in-Chief

Annually, E&MJ offers a roundup of activities among suppliers from the Nordic region. Several major mining and mineral processing equipment manufacturers (OEMs), as well as emerging small- and medium-size suppliers, are headquartered in the region. The surrounding hard rock mines that lie at or above the Arctic Circle often serve as the proving grounds.

Mining in the Nordic region dates back three centuries and it’s an important part of their culture. Using the experience they have gained, they have developed or continue to upgrade equipment and technology. For many of them, placing their equipment in the mines and mills is the first step. Letting the explorers, miners and mill superintendents test the gear is an achievement. If they earn that Nordic stamp of approval, they know their equipment will work anywhere.

What follows is a digest of equipment and service-related concepts from the Nordic region. Most of it was brought to E&MJ’s attention by readers in the region. While the major original equipment manufacturers (OEMs) want to maintain their position as industry leaders, the small- and medium-sized companies hope to export their services to other major mining districts around the world.

SANDVIK DISCUSSES DEVELOPMENTS IN AUTOMATION

Automation has become a buzzword for the mining business—not just on the surface, but also underground—and Sandvik Mining is in tune with that. “The awareness and interest for more productive and safer equipment has clearly increased over the past few years,” said Riku Pulli, vice president of automation for Sandvik Mining. He believes that awareness has been heightened by more and more successful reference cases as well as the clear link to the current challenging market where mines have been forced to find new and more cost-effective ways to extract ore.

Overall, industrial digitalization can also be clearly seen in mining, Pulli explained. “Mining companies are looking for ways to make the entire process more continuous including real time control and overall transparency of operations,” Pulli said. “With today’s technology, such as mine-wide digital communications, robust sensor technology and industrial computing capacity, many of the past bottlenecks can now be removed. Along this process, the amount of generated and stored data is now growing exponentially and this will soon lead to further exciting opportunities.”

Sandvik launched automated long hole drilling more than 20 years ago. In 2004, the company developed semiautomated LHDs delivering the first systems to El Teniente in Chile and Pyhäsalmi in Finland. Sandvik worked with DeBeers to launch a fully autonomous underground trucking system at the Finsch diamond mine in South Africa in 2006. A similar system was installed at the Williams gold mine in Canada in 2008. Several other successful load-and-haul (L&H) automation systems followed including Northparkes in Australia, Kiruna and Garpenberg in Sweden, Kidd in Canada and just recently Tara mines in Ireland.

One of the new features Sandvik has included in the AutoMine Loading product is the automatic bucket filling technology, which makes the LHD operating cycle fully autonomous when a computer also knows how the bucket is loaded quickly and efficiently. All the other parts of the cycle, including tramming, tipping and traffic management were previously automated.

In the past few years, there’s been a strong focus on expanding the automation platform to surface drilling applications. “Sandvik now has a comprehensive automation package for single rigs or large fleets ranging from smaller DP-series top hammer drills to the large DR-series rotary drills,” Pulli said. “The new product allows fully autonomous operation and supervision from a distance. The control center can be mounted in a mobile trailer or a van or it can be located in a mine’s control room further away from the bench.”

Sandvik has been working intensively on advancing automation for underground drilling. The new DD422i development jumbo is a prime example. “The DD422i has plenty of automation built into it, including automated face drilling, data transfer, supporting office software, etc.,” Pulli said. “This is now the platform the other underground drills will share in the short term, including long-hole drills and bolters. These units can also be remotely operated from a control room using the AutoMine platform.”

As Sandvik has traveled along this 20-plus-year path developing more and more automated equipment, it quickly realized the importance of creating an overarching information management system that integrates equipment and interfaces with other aspects of the mining process. Sandvik’s offering now includes a modular and fully integrated information management system that allows customers to:

- Remotely monitor the equipment performance and condition;

- Schedule short-term activities (shift);

- Allocate and manage tasks in real time and monitor the progress;

- Track equipment in real time with centimeter accuracy (underground positioning system); and

- Share all the data with third party system based on open architecture and interfaces.

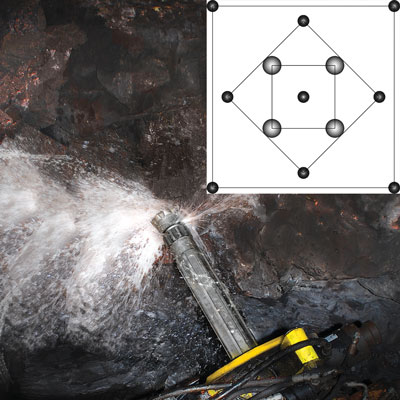

Wassara drilling in action (Inset: The 1.2-m x 1.2-m drill pattern.).

Wassara drilling in action (Inset: The 1.2-m x 1.2-m drill pattern.).The potential upside from automation has been well documented. Improved operating safety is an obvious benefit, especially when miners are removed from hazardous working conditions. In addition to safety, many Sandvik customers have reported significant increase in equipment utilization and reduced operating costs when using automation, Pulli explained. “At the last Austmine conference, Northparkes reported a 23% increase in daily production when using AutoMine loaders, with 24% lower operating costs,” Pulli said. “Finsch has also seen a 26% increase in productivity by having truck availability out 14% and utilization 24% higher compared to manual operation. Kidd also reported significant productivity gains right after implementing AutoMine Loading Lite with more tons being remotely loaded during shift changes and blast windows.”

There are concerns related to automation if a large, advanced automation system is implemented at a mine without proper change management process, Pulli explained.

“Sandvik has worked already with many customers to address this question successfully and they can now choose a step-by-step approach where they can start with more basic automation and gradually bring in more when the time is right.”

Modern mines are becoming rock factories where the process has become continuous and it can be monitored and controlled in real time. “It’s incredibly exciting to see that the visions of automation that have been discussed over and over again in the past two to three decades are now becoming a reality, and this is still just the beginning,” Pulli said.

“There is so much more in the pipeline.” The use of automation and information management will become a standard technology that enables mines to produce more tons safely and cost effectively.

MECHANIZED SLOT DRILLING

The San Geronimo underground copper mine, located in Chile, was facing the same challenge as many underground mines—the ability to efficiently create open slots in a safe manner. The slots provide a free face (or void) for fragmentation in production blasting. The mine approached Wassara, knowing that, when it comes to drilling a long-hole rise, the company’s down-the-hole (DTH) hammers drill straight holes efficiently and impart less stress on the host rock.

Previously, the staff at San Geronimo used the traditional air leg raise miner for the opening slots. A miner worked his way up the hole on ladders and drilled and blasted, cut by cut. This method was not very productive and posed a great hazard for the raise miner. To create one open slot with the dimension of roughly 1.2 m x 1.2 m and 20 m in length with this method, it took three to four miners roughly 28 days. In a search for alternatives to drilling the open slots, the use of a box-hole rig was quickly eliminated due to the high cost and requirement of large development drives.

The ideal solution would create open slots with existing equipment and technologies in the production, like the drill rigs used for the long blast holes. This has been tried by many mines, but with unsuccessful results as the requirements of very straight holes couldn’t be met. In a long-hole rise, the holes are positioned very close to each other, sometimes as close as 20 cm. In these 20-m-long holes, it equals 1% of borehole deviation.

With the very tight spacing between the holes in a long-hole rise, it is important that the drilling process doesn’t create or prolong existing structures and voids in the host rock. If this happens, the blast holes might get connected to each other with explosives during the charging process. If so, undesired initiation of the explosives will happen during the blasting sequence oftentimes leading to poor fragmentation. With conventional drilling technologies, it is very hard to keep the holes parallel, which is the key to achieve an successful blast of the long hole rise.

Wassara’s water-powered DTH hammer enables very straight holes with less than 1% deviation in traditional lengths of long hole rises. The successful reference from the LKAB mines in Sweden, where the Wassara hammer is being used for long hole rises up to 35 m in length, made the choice easy for the mine.

The mine made modifications to a rig (such as a rotation unit and breakout table) to use the Wassara DTH hammer.

The drill pattern of the long hole rise consisted of 82-mm (3.25-in.) blast holes and 127-mm (5-in.) open void holes. The length of the long hole rises varies around 20 m and is 90° upward and has about 70° side rotation.

The Wassara W70 hammer is used for the 82-mm holes, while the Wassara W100 hammer is used for drilling the 127-mm holes. It takes three to five days to complete one long hole rise with Wassara. Comparing it to the method they used before, that is a factor of four to five times as fast, and more importantly it eliminates the hazards that comes with air leg raise mining.

They surveyed the drill holes to measure the deviation, using the Reflex system as surveying method. All holes had less than 1% deviation while many of them had close to zero. To date, the mine has drilled 10 long hole rises and they require about two long hole rises per month to meet production requirements. The rate of penetration in this formation was 0.8 m/min with the W100 hammer and 1 m/min with the W70 hammer.

CONCRETE SPRAYING MACHINES

Finnish underground equipment supplier Normet introduced its new concrete sprayer at a mining exhibition in Tampere, Finland, earlier this year. The Spraymec 5070 VC was designed for medium capacity spraying work, and can be considered the “little brother” of Spraymec 8100 VC as it uses the same high performance carrier but comes with somewhat lower capacity spraying features.

New features include a new spraying boom SB307 providing adequate reach in tunnels with profiles up to 7 m. The boom is equipped with self-lubricating slide pieces and roller to minimize wear and tear. All the boom movements are pressure compensated and have proportional functions allowing the operator to create a smooth and homogeneous tunnel lining structure.

The Spraymec 5070 VC uses Normet’s low pulsation concrete spraying pump (NSP30) with a theoretical concrete output of 28 m3/h. An onboard screw compressor provides a reliable air supply for medium capacity spraying jobs.

The same intuitive nozzleman’s interface is available for the Spraymec 5070 as is standard for the Spraymec 8100. This includes the operator being able to carry out all spraying functions from the radio remote control and follow spraying process parameters though a turntable and movable multicolored display placed on the front of the machine. Service convenience is assured with open access to all service points.

The Norsmart control system can log all spraying process and carrier data such as concrete and accelerator volume, dosing percentage, pumping speed, change of process parameters, engine and compressor hours, hydraulic oil system pressure and temperatures etc. The NorSmart system also provides full fault diagnostics.

Normet’s Spraymec 5070 VC.

Normet’s Spraymec 5070 VC.FLOWROX WINS VALVE PROJECT IN NAMIBIA

Flowrox recently won a project to supply the Husab uranium mine in Namibia with 83 550-mm hydraulically actuated pinch valves. They will be used for the mine’s tailings operation that will span more than 23 km2. The valves will be operated by means of two mobile gasoline-powered hydraulic power packs whenever required.

In addition to the valves themselves, Flowrox has conducted competence training for the mine’s technical staff, ensuring a high level of sustainable plant operability. A healthy amount spare parts will enable mine staff to carry out any service and repairs if and when required.

“Husab only partners with the premium product suppliers in this market sector and Flowrox was chosen due to our quality performance,” said Henlo Blignaut, who was appointed managing director, Flowrox Pty Ltd. South Africa in June. He sees the situation in Southern Africa as challenging, but he is confident about future prospects.

ROCKDRILLS FOR COMPACT LOADERS

The Doofor DF530X hydraulic rock drill is mounted on a Avant compact loader.

The Doofor DF530X hydraulic rock drill is mounted on a Avant compact loader.Two Finnish manufacturers, Doofor and Avant Tecno Oy, are bringing new rock drilling solutions to the world market. The Avant D22x drill attachment can be installed for Avant 635, 640 and 700-series compact loaders and it can drill up to 45-mm-diameter holes in hard rock. The D22x drill attachment includes Avant quick-attach system and hydraulic multiconnector for a quick installation. The drifter is a Doofor DF530X hydraulic rock drill, which has a 7/8-in. hexagonal female chuck and can use both air and water as drill hole flushing media. The complete attachment weighs 205 kg and it is equipped with a hydraulic 90° tilt to vertical drilling. “We see a lot of potential for this kind of compact, robust, but effective drill attachment,” said Avant Tecno’s Jukka Kytömäki. “There are a number of existing Avant-users in need of such an attachment. This also makes the Avant-loaders yet more versatile, which adds to the number of future Avant owners.”

Doofor also recently introduced the DF540L-BLT, a bolting and grouting rock drill in the 14-kW size class. The rock drill has been designed symmetrically to give miners and rig developers as much free space for design as possible. With no top or bottom, the unit is completely “flappable.” The DF540L-BLT is also quite short in relation to its power.

The DF540L-BLT offers double sealing for grouting purposes. The seals are also accessible and easy to maintain. The flushing chamber is also placed so that the water doesn’t enter the rock drill even in an unlikely case of seal failure. The rock drill has an oversize and very robust rotation gear, which it shares with the bigger Doofor rock drill models DF560L and DF550L. The rock drill design is simplified to reduce maintenance costs by lowering the number of pressure seals.

The DF540L represents Doofor’s latest vision in lowering the oil flow needed while keeping a good rock penetrating power.

JAMA SUPPLIES MACHINES TO KITTILA

The Jama 8000 series has a PLC control system integrated into a 15-inch touchscreen monitor.

The Jama 8000 series has a PLC control system integrated into a 15-inch touchscreen monitor.Jama Mining Machines, which is based in Skelleftehamn, Sweden, recently received its first export order to Finland for mining rigs in the Jama 8000-series. Europe’s largest gold mine, the Agnico Eagle Kittilä mine in northern Finland, purchased a mechanical scaler and a shotcrete rig from Jama.

“The Jama machines are leaders in their niche. When Jama also could present a trustworthy concept for service and support, we became confident to choose them as our supplier,” said Kyösti Huttu, chief mining engineer at Kittila, who has been responsible for the technical aspect of the purchase agreement.

“We see this as a breakthrough in Finland since the Kittila mine is regarded as Finland’s most modern mine and is considered as a role model and trendsetter for the country’s other mines,” said Anders Norberg, business development manager and responsible for export sales at Jama Mining Machines.

At the end of last year, Jama launched the latest version of its 8000-series machines, the 8000B. It has a Deutz diesel engine that meets emission class Tier 4 final, which reduces emissions to an absolute minimum. It also has a new PLC control system integrated into a 15-in. touch-screen monitor. The operator interface is user friendly. The system has a redundant CAN-bus technology, Ethernet communication and a simplified troubleshooting tool.

In March, Jama added rescue chambers and lifts, and various utility vehicles to its product portfolio when its parent company, Högkammen, acquired Bergteamet AB. The products in Bergteamet division-MEC were placed under Jama Mining Machines. In addition, Jama is also now selling a Wheel Carrier system, which had been marketed under Högkammen’s Komab Industriteknik subsidiary.

GRINDEX CELEBRATES 75 YEARS

The Grindex Primo submersible pump.

The Grindex Primo submersible pump.Founded in Sweden in 1940 for produce equipment for the Swedish navy, Grindex is a company with extensive experience in the engineering field. It has now evolved into one of the global leaders in submersible dewatering pumps. In 1960, the company developed the first dewatering pumps able to run dry with a revolutionary air valve. Since then, the products have changed to reflect customer demand, but Grindex has maintained a strong focus on quality.

More recently, Grindex introduced the Primo range suitable for tough dewatering applications. The pumps are often found working in media containing chemicals or in otherwise contaminated environments. Because of the affordable price, it can be advantageous to fit a new one and dispose of the old unit in an environmentally responsible manner.

OUTOTEC INAUGURATES DEWATERING TECHNOLOGY CENTER

Outotec recently established a Dewatering Technology Center in Lappeenranta, Finland is dedicated to developing new products, processes and services for solid-liquid separation, and raw material reuse. With the new Dewatering Technology Center, Outotec can simulate and optimize customer processes to integrate them with Outotec technology to capture new levels of efficiency throughout the life cycle of a plant.

“With the recent acquisition of Kovit Engineering and Outotec’s expansion into tailings management solutions, the new dewatering technology center brings world-class knowledge in the study of tailings dewatering and treatment. Cooperation with our research partner Lappeenranta University of Technology further supports us in developing more efficient and sustainable total solutions for our customers globally,” said Kalle Härkki, head of Outotec’s Minerals Processing business area.

PROVIDING POWER IN KAZAKHSTAN

Finland’s Wärtsilä will supply a 40-megawatt (MW) Smart Power Generation power plant for LLP KazAzot in Kazakhstan. The company, located near Aktau, produces anhydrous fertilizer and ammonium nitrate. The power plant will provide electricity and steam for process and it is scheduled to be operational in late 2016.

“Also, Wärtsilä’s capability to extend the scope of supply to include both the steam cogeneration plant and the civil materials were important factors influencing our choice,” said Kinis Urakov, CEO of LLP KazAzot.

The extended equipment delivery includes four Wärtsilä 34SG engines running on natural gas, cogeneration units for steam generation, mechanical and electrical accessories balance of plant, as well as civil materials supply.

Wärtsilä has delivered approximately 2,800 MW of power generation capacity to Russia and other CIS countries. Globally, Wärtsilä’s installed capacity is 58 GW in 175 countries.

HYPERSPECTRAL SENSOR FOR UAVS

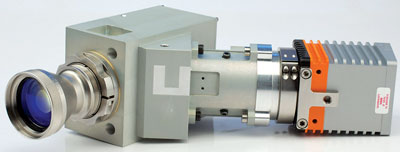

The AisaKESTREL 16 camera has a spectral range from 600 to 1,640 nm.

The AisaKESTREL 16 camera has a spectral range from 600 to 1,640 nm.The AisaKESTREL push-brooming sensor systems integrate the experienced gained in SPECIM’s 20 years of airborne hyperspectral remote sensing. “When it comes to detecting vegetation, water or soil attributes of minute spectral differences, there are simply no alternatives in the market compared to the radiometrically and spectrally stable data and high signal-to-noise ratio, as provided by AisaKESTREL in variable real world remote sensing conditions. You may find lighter sensors than 5 kg, but not without serious compromises in the data quality,” said Petri Nygren, sales manager for Airborne Systems at SPECIM. “Landsat started spectral remote sensing with GSDs at the 100-m level. Aircraft mounted AISA sensors brought GSDs to 0.5- to 1-m level. Now for UAVs, we have broken even that GSD barrier down to a 5- to 10-cm level, first time with professional data quality. While 5- to 10-cm GSD is the norm with other airborne sensor technologies, such orthophoto cameras and LiDARs, hyperspectral data is perfectly complementary in a multitude of ways. This marks a completely new era for creating added value through remote sensing.”

Based in Oulu, Finland, SPECIM Spectral Imaging Ltd. is a world leading manufacturer of hyperspectral imaging instruments and systems. In addition to AISA airborne remote sensing systems, the company provides ImSpector Imaging Spectrographs, Spectral Cameras and Hyperspectral Imaging Solutions.

ELEMENTAL ANALYZERS

Xore’s Boxray 24 elemental analyzer.

Xore’s Boxray 24 elemental analyzer.Xore’s Boxray on-stream elemental analyzers are commonly found in concentrators.

The Boxray 24 has a carousel with 24 measurement cells. Each stream has its own measurement cell eliminating the risk of cross-contamination of samples. Flushing the cells between measurements is made while an other cell is being analyzed, allowing shortest possible cycle times. The secondary sampling tanks are fully automated. Daily samples are collected in “tea pots,” which are drained in the sampler tank stand—very convenient for the lab personnel as the samples will only be slightly humid when they are collected, which saves time when drying the samples in the lab.

The smaller sibling, the Boxray Compact, does not have all the features of the Boxray 24 but is more affordable.

It has three measurement cells mounted on a linear guide. Two cells are for samples and the third holds a reference briquette. A multiplexer system is then used to allow up to 16 samples. The analyzer automatically changes between the two measurement cells. As one cell is being analyzed the other one is flushed and filled with the next sample. The Boxray Compact has the same automated collecting of daily samples in the secondary sampling/multiplexing tanks as the Boxray 24, with drained pots.

Using the Boxray Compact to monitor copper content in electrolyte is an economic way of achieving full control over a tank house. The data from the analyzer can be displayed in the control room or retrieved automatically to the plant control system and thereby creating a fully automated process. The operators will at the same time be able to monitor content of precious metals or contaminants from the ore.

RUGGED COMPUTERS FOR MINING APPLICATIONS

The Rugged JLT computer has been placed in the cab of a mining vehicle at one of Boliden’s Swedish gold mines, highlighting its versatility and durability.

The Rugged JLT computer has been placed in the cab of a mining vehicle at one of Boliden’s Swedish gold mines, highlighting its versatility and durability.Based in Växjö, Sweden, JLT Mobile Computers are recognized as some of most rugged, reliable, high-performance vehicle-mounted computers on the market.

Earlier this year, JLT announced a significant technology leap for its products by upgrading their wireless connectivity, giving miners immediate access to the best wireless WAN, LAN and Bluetooth performance, according to the company.

Wireless connectivity is now arguably the primary method of communication, particularly for mobile computers. By investing in upgrading its existing product portfolio, JLT is leading the way in making rugged computing more accessible and reliable for all mobile users. Using wireless technologies in harsh environments can present end-customers with unique challenges; JLT Mobile Computers’ expertise in developing robust and reliable equipment for use in exactly these environments makes it a leading solutions provider in its field. Ensuring a reliable wireless connection in working environments where most technologies would be rendered useless requires a sophisticated connectivity solution leveraging the latest technology.

Advanced Braking Technologies for Conveyors

Spring-applied, hydraulically-released BSFH 520 brakes act on a 1.6 m diameter disc mounted on the low-speed side of the drive shaft. The brake system provides up to 182,160 Nm nominal braking torque to stop the conveyor in a controlled manner over a 50-second time period.

Spring-applied, hydraulically-released BSFH 520 brakes act on a 1.6 m diameter disc mounted on the low-speed side of the drive shaft. The brake system provides up to 182,160 Nm nominal braking torque to stop the conveyor in a controlled manner over a 50-second time period.Today, mining conveyor OEMs are building even larger, more complex conveyors that combine greater strength and capacity for increased productivity. Mine operators are demanding braking systems that are more intelligent, quicker and more user-friendly.

Denmark’s Svendborg Brakes introduced the first generation of the Soft Braking Option (SOBO) controller in 1998. It provided smooth, controlled braking on mining conveyors around the world. Over the years, pulse width modulation (PWM), pulse frequency modulation (PFM), and a combination of both methods of the SOBO controller were introduced. These models provided improved control for low-torque/low-volume hydraulic brakes and reduced oil flow, an important feature to achieve long controlled braking in case of power failure.

In February, Svendborg Brakes debuted the new SOBO iQ at the Society of Mining Engineers annual conference. It represents the latest technology in braking, which includes brakes, hydraulics and the SOBO iQ controller.

“The first version of SOBO was basically a black box that the customer didn’t have to think about,” said Soren Holm, Svendborg area sales manager for Chile and Peru. “But today, mine operators need and want to know what’s going on in every area of their facility. The SOBO Q empowers mine operators as it provides all conveyor braking data online for easy access.”

The SOBO soft-braking controller benefits and features include:

- Controlled braking independent of load and load position;

- Braking on time or distance;

- Adjustable brake ramp/curves;

- Compensating for variable friction factors;

- Controlled startup;

- Real-time monitoring of brake sequence time; and

- BUS communication with customer PLC.

The system controls braking torque based on preset speed ramps and actual speed and system pressure feedback. Different braking profiles are provided for different scenarios. Advanced functions including independent overspeed monitoring, rollback and gear monitoring are integrated into the control box.

The System Functions Similar to a VFD SOBO iQ features a revolutionary dual-loop PI control (pressure/speed) and an internal pressure control loop. Pressure control is not only based on speed but also on deceleration. The control provides only the torque needed for a safe, controlled stop. Units have three-state digital modulation—never used in a braking system before. Each controller can accommodate up to 4 HPUs with defined torque sharing. Other features include full BUS-based communication with the master control system. Remote access and touchscreen for setup and monitoring are also available.

“The SOBO iQ controller offers customers enhanced functional flexibility,” according to Robin Schmidt, Svenborg application specialist for North America. “It can be used as a backstop, a dynamic brake and a parking brake all incorporated in the same system. Users can get signal feedback for all the braking system functions.” The control utilizes different communication ties plus different communication protocols. Users can easily access and change the parameters inside the control, such as defining a parking sequence or pre-setting a stop time.

Jan Mikyska, a Svendborg engineer who helped develop the SOBO iQ, explained, “Control flexibility also means we can stop the conveyor—no matter if it’s fully loaded or empty—in the same time or distance, depending on what the customer needs. We simply add ‘S’ curves with specific desired braking profiles.”

“For example, when you want to stop your truck, you apply hard pressure to the brake pedal,” he said. “When the truck is almost stopped, you begin lifting your foot. We can apply the same kind of curve to the SOBO system. So when the conveyor is almost stopped, less braking force is used. Or, a two-stage mode can be inserted to put the same pressure onto the stops. It depends on the situation, whether its a normal stop or an emergency, but in all cases the conveyor can be stopped in a smooth, controlled fashion.”

The SOBO system is also capable of providing additional dynamic braking functionality. For example, in a situation where the motor VFD loses control of the conveyor due to material overload, causing the conveyor to accelerate beyond its normal running speed, the SOBO can be set up to send an over speed alarm to the main PLC. The main PLC then decides whether a full SOBO stopping ramp should be initiated or if it is preferred to just bring the conveyor speed back to normal running speed again (in this case, the brakes will be programmed to automatically release when normal speed is reached and let the conveyor continue to run).

Svenborg recently supplied a complete braking systems for use on a series of three downhill in-line conveyors at a large copper mine in Chile. Two of the conveyors are 1,600 m long and another is 700 m long. The copper mine’s conveyors can transport 5,000 metric tons per hour (mt/hr) with a belt speed of 5.5 m/s. The braking systems provide emergency stopping and parking functions. Each conveyor braking system consists of two model BSFH 520 caliper disc brakes, a SOBO controller, a hydraulic power unit and disc.

The spring-applied, hydraulically-released BSFH 520 brakes act on a 1.6 m diameter disc mounted on the low-speed side of the drive shaft. The brake system provides up to 182,160 Nm nominal braking torque to stop the conveyor in a controlled manner over a 50-second time period.

The three SOBO controllers allow the mine to give a brake command to each conveyor brake system at the same time, or they can program a delay if desired. In this case, they give the same brake command at the same time for the three conveyors. The brake control can be set up with three to four different stopping ramp programs.