Dr. Matthias Wimmer is the manager for mining technology at LKAB’s Kiruna operation. (Photo: LKAB)

LKAB’s Kiruna mine will soon start testing a new mining method called raise caving. E&MJ spoke to Dr. Matthias Wimmer to learn more about the technique and its origins.

By Carly Leonida, European Editor

On May 28, Swedish miner LKAB announced it was working with industry and academic partners to develop and prove a new mining method called raise caving. The concept literally turns traditional cave mining on its head, and once proven, the benefits could extend the life of LKAB’s underground operations (and others around the globe) by years as well as unlocking new deposits.

E&MJ caught up with Dr. Matthias Wimmer, manager for mining technology at the Kiruna mine in Sweden, to find out more.

“It all started with a drawing on a napkin,” Wimmer said. “I was with some colleagues, and we were discussing how to solve some of the problems that cave mines are facing nowadays. Most challenges are related to seismic activity, which increases as operations mine deeper and extraction rates increase. We realized that, to address these problems, we needed to solve the root cause rather than just trying to engineer better ground support.

“We were looking at some deep mines in South Africa, some of which are 3- or 4-kilometers deep, but they have smaller tonnages, maybe 2,000-5,000 metric tons per day (mt/d). We were looking at how we could take some of the destressing concepts they use and apply them to mines that are producing 80,000-150,000 mt/d or more.”

Most methods used at deep South African mines are designed to extract flatter, vein-hosted orebodies. To make these work for steeply inclined orebodies like LKAB’s and, to extract massive amounts of material, would require adaptation as well as innovative technologies.

“We believe that steeply inclined orebodies are best mined with a vertical development approach,” Wimmer said. “We feel quite confident that raise mining technologies like Alimak and the ROES concept — an automated extraction concept based on vertical bulk raise mining that was developed in Australia — could be applied in raise caving.”

“Our main level at Kiruna is at 1,365 m,” Wimmer said. “And our current deepest mining level is at approximately 1,100 m. But it’s questionble whether large block cave mines like this can go much deeper with current methods. This has to do with the rock stresses that increase with depth but also the seismic energy that’s released and that is connected to the tonnage — the more you mine, the more seismic energy you release.”

How Does Raise Caving Work?

Today, LKAB uses large-scale sub-level caving in its underground mines with great success. However, the challenges and costs are mounting as depths increase. While the company is looking to improve its sub-level caving practices, raise caving could also complement it or be used as an alternative method in certain situations.

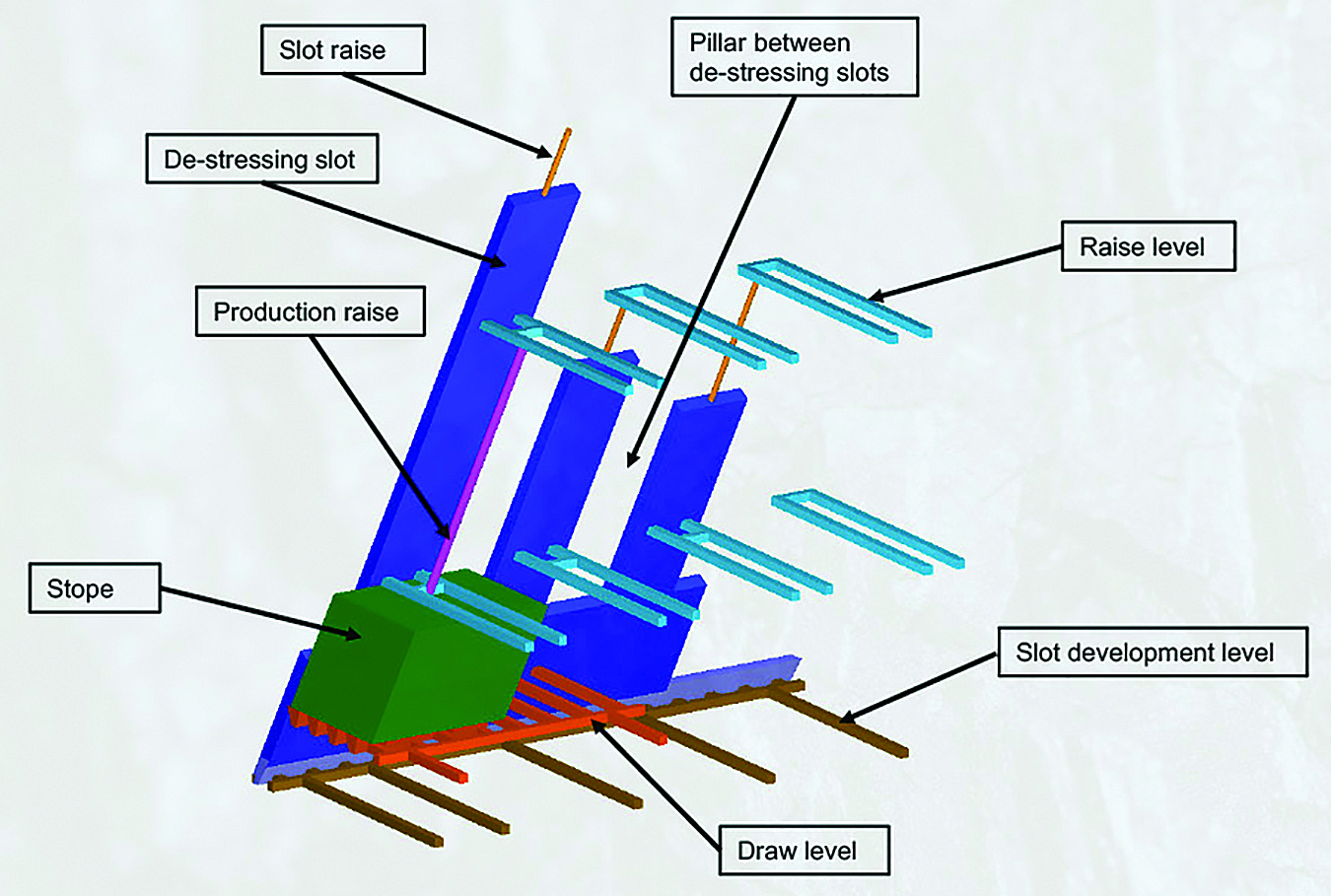

In raise caving, the deposit is initially destressed with slots developed from raises. Pillars separate the slots in order to control stress magnitudes and seismicity during destressing. The slots provide a stress shadow for production infrastructure so that stoping can take place in destressed (safe) ground. As mining progresses, the pillars deform and are eventually extracted, and the hanging wall allowed to cave. This sequence continues in slices across the orebody.

“It’s the destressing slots and also the interaction between the stopes that provide the stress shadow. As the stress shadow grows, you can think about placing another stope or even ore passes in the stress shadow,” Wimmer walked E&MJ through the process. “Unlike most caving methods where the majority of the parameters related to the mine design, such as the drawbell shape, drawpoint positions, drift spacings, undercut strategy, etc. are locked in from the beginning, in raise caving, the majority of infrastructure is built on demand. The mine evolves and develops as the orebody is destressed.”

The deposit is essentially mined from the bottom up, rather than the top down and this produces several advantages compared to traditional caving methods. In combination with good draw control, it allows more ore to be mined with less dilution and, because seismic activity is controlled or directed to designated areas, risks to active infrastructure and employee safety are significantly reduced.

In raise caving, the deposit is mined from the bottom up, rather than the top down and this produces several advantages compared to traditional caving methods. (Image: LKAB)

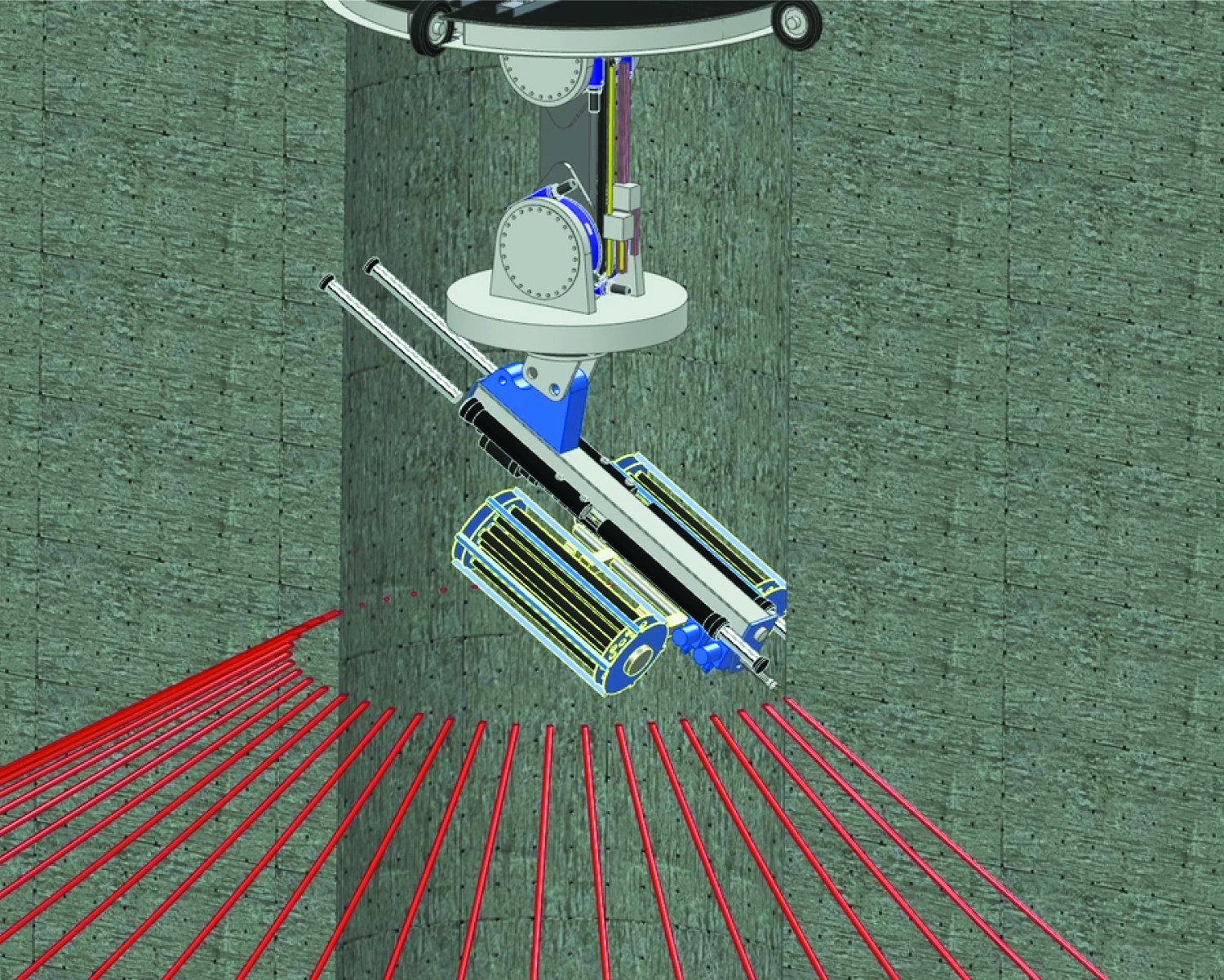

During the raise cave mining sequence, a raiseboring machine would be used to develop a drawbell and then a smaller diameter slot raise would be drawn upward through the slice. A cylindrical drilling platform, similar to the galloways used in shaft sinking only on a much smaller scale, would be lowered in the raise to a position just above the drawbell (or the cave). A remote-controlled, rotating drilling boom on the bottom of the platform would drill blastholes downward radially along the perimeter of the raise. Another remote-controlled machine would charge the holes. The blast would undercut the ore, caving toward the drawpoint at the bottom.

Because mining starts in the raises rather than in drifts, no personnel are exposed to drilling and blasting. By reducing the need for drifts, infrastructure requirements ahead of mining can also be reduced by a colossal 50%, which not only speeds the time to ore but also cuts operator’s capital requirements and exposure to risk significantly.

“We’re literally turning the current system upside-down,” Wimmer said. “It requires a big change in mindset as well as the approach because sometimes, with such radical changes, people can feel criticized, but there’s nothing wrong with the current system. The situation just changes with depth and therefore our methods need to as well.”

The team drew inspiration from the South Deep mine in South Africa, which is mining at around 3.1 km depth. South Deep has a slightly inclined orebody and uses destressing slots relying on a system of drives and pillars, which have the function of yielding and crushing. This system provides a stress shadow that allows mining to take place underneath in a favorable environment.

The team took inspiration from the destressing techniques used at South African mines like South Deep (shown here) to develop the raise caving concept. (Image: LKAB)

“We wanted to create a similar system but for steeply inclined, mass mining operations,” Wimmer said.

Flexibility, Today and for the Future

In theory, raise caving is a very efficient and flexible method compared to other mass mining techniques. With methods like block caving, undercut levels and drawbells must be created in advance and the orebody preconditioned using drilling and blasting and possibly hydraulic fracturing (hydrofracking). This systematic approach works well, but it requires time upfront and can add a lot to production costs.

“With raise caving, the raises can be placed through the production stopes, and they can also be used for drawbell and undercut development, which we believe is valuable in terms of functionality because you never change the direction of blasting,” explained Wimmer. “You’re using gravity and always blasting downward to create the very best requisites for optimal fragmentation.

“In addition, we aim to create a new concept for a large drawbell design with multilevel access for extraction. This enables, among other things, better ore flow (more equidistant drawpoint spacing), delayed development of drawpoints into the drawbell, and provides economy for the raises needed. You can also be really selective with the use of preconditioning, and it can be done on demand during caving, maybe to guide the cave in a certain direction or to force caving if the cave doesn’t propagate. And, you have a fallback situation in that you can still go in with drill-and-blast if things don’t work out with the raise mining system.”

Wimmer is confident that raise caving could not only match Kiruna’s current production rates, but also exceed it in certain conditions.

A remote-controlled, rotating rig on the bottom of the platform would drill and load radial blastholes inside the raise to undercut the cave.

“I don’t see any limitations that would prevent raise caves from reaching the production targets of super caves in the range of 150-200,000 mt/d,” he said. “It’s just a question of having enough stopes in operation at a time, and these stopes are quite large. Take a footprint of 50 m x 50 m and a burden of 3-4 m… you can easily get a few 10,000 mt per each and every blast, if you blast the ore, for instance.

“That is a factor of three or four times larger than we have today in our current blasting operation.”

Raise caving could also potentially be used to extract quite competent and narrow orebodies. This could enable operators that have so far hesitated on developing cave mines to move into action. And therein lies an important point, LKAB plans to share its experience and learnings with other mining companies.

“In general, we are very open with new mining methods,” Wimmer said. “We have been approached by several major mining houses about raise caving. This shows us that we are on the right track, but it’s also important that we get acceptance from the industry and build trust, which helps us when we have to invest large sums into the development of future mines.”

Partnering to Prove the Concept

For the desktop study, LKAB is working closely with the team at Montanuniversität Leoben (University of Leoben) in Austria, the country’s university for mining, metallurgy and materials. Professor Horst Wagner, chair of mining engineering and mineral economics at Leoben, was formerly general manager of the South African Chamber of Mines and has brought vast technical knowledge around deep mining and destressing of rock masses to the project. The technical lead from Leoben is Tobias Ladinig, a passionate senior researcher in the field of rock mechanics. Wagner and Ladinig are joint inventors of the raise caving method.

Leoben has a proven record of working together with mining companies on mine planning projects, and the next step is

for the teams to test both the mining method and the machinery (LKAB is developing a brand new raise mining machine); the two projects will run in parallel.

For the mining method proof of concept, LKAB has designated a test area and development is scheduled to start in 2022. The aim is to test raise caving as a standalone method, but also whether it’s possible to transition a mine from a traditional cave mining technique — in this case sub-level caving — to raise caving. In theory, it should be possible, but the proof will be in the pudding.

“We want to verify the mining method underground in a high-stress environment but, initially, we would like to accomplish this independently from the machinery tests,” Wimmer said.

“It’s all about monitoring and seeing whether we can achieve the desired destressing effect and whether the pillars behave as expected. For the machinery,

we have a few prototype tests pending for next year. We’re planning, for instance, for the charging equipment to be shown next year in a test environment — we are developing that together with ABB. Once the machinery is available, we may use it to put in the raises. But there’s no benefit in putting the machinery into a high-stress environment right from the beginning.”

LKAB has a research mine located south of Kiruna, so the first machinery components could potentially be tested there.

“Right now, we are carefully planning and designing the tests to give the method a fair chance,” Wimmer said. “Also, we don’t want to interrupt the mine’s

current production.”

LKAB is drawing upon the expertise of its various subsidiaries as well as industry partners to advance the new machinery. The concept is based on a raise mining platform fitted with modules for various duties like drilling-and-charging and ground support.

“We’ve got in-house subsidiaries like Kimit, which is an explosives manufacturer, Wassara, our drilling technology subsidiary, and locally, we have some very strong engineering companies,” Wimmer explained. “We are also working with a local coordination partner, a company called Necab.

“We currently do hydrofracking of the footwall for seismic reasons. For the principle of advancing the stope with fracking, we’re looking to modify the equipment so that it fits into the raise. We also need to look into relocation of the machinery — although it is fairly permanent — as well as maintenance. Each module needs to be tested individually and then as a whole system.

Innovation Equals Longevity

Using raise caving to solve some of its rock mechanics challenges is just one way in which LKAB is looking to secure the future of its operations. Wimmer explained that incorporating techniques like backfilling to control surface deformation (provided good draw control is exercised) could also have a positive effect on grades and recovery capacity.

“We are really drastically pushing down the OPEX costs with such methods,” he explained. “But our main route is sub-level caving and adapting it to the depth. We want to push the sub-levels from 30 m to 40 or 50 m. We want to put in high levels of automation, and also use a fork layout along with a combination of LHDs and trucks to allow longer tramming distances. We want to push the infrastructure further into the footwall, which we believe is advantageous from a seismic stress point of view, together with using hydrofracking.

By reducing the need for drifts, infrastructure requirements ahead of mining can also be reduced by 50%.

“Then we’re looking into other caving methods such as incline caving and block caving. Raise caving though is a very attractive route because it tackles many of the problems associated with depth and seismic activity. I think we can further engineer the ground support and push, with hydrofracking, down to the current main level. But to go deeper than 1,400 m with mass mining, you need to do something more about stress management incorporated in the mine design.”

LKAB’s Alternative Mining Methods project is evaluating different mining methods, or combinations of methods, for three of its current mine sites: Kiruna, Malmberget and Svappavaara. Raise caving will be included in this going forward.

“The work takes further into account rock challenges and safety, ore flow, the mining systems, ventilation, the hoisting and transportation system and much more,” Wimmer said. “It forms the basis for a full economic and risk-based analysis of each approach, and the evaluation process will go on until 2025 for all three sites in order to take a decision on which sites to advance and in which way.

“It’s a very holistic approach and we would like to do this as generically as possible, rather than trying to find individual solutions for each and every mine site.”