Diesel-powered pumps and a remote pump control station improve a mine operator’s pit dewatering efficiency and safety

Xylem has been a major player in the diesel/electric dewatering pump market since it acquired Godwin Pumps in 2010. Recently, the water-handling solutions provider reported on a successful pit-dewatering project for one of its customers in Latin America.

A mining company in Peru needed to drain water from a large open-pit operation that reached as deep as 1,200 ft (365 m) to pit floor. The discovery of additional copper mineralization in the mine, as well as the large amount of precipitation that falls during the rainy summer months, prompted the company to seek a solution that would allow its workers to remotely monitor and control pumps at the pit bottom. After analyzing the problem, pump experts from Xylem’s Peru office determined that the best solution called for Godwin surface-mounted, diesel-driven pumps controlled by a remote monitoring system.

A mining company in Peru needed to drain water from a large open-pit operation that reached as deep as 1,200 ft (365 m) to pit floor. The discovery of additional copper mineralization in the mine, as well as the large amount of precipitation that falls during the rainy summer months, prompted the company to seek a solution that would allow its workers to remotely monitor and control pumps at the pit bottom. After analyzing the problem, pump experts from Xylem’s Peru office determined that the best solution called for Godwin surface-mounted, diesel-driven pumps controlled by a remote monitoring system.

“The operation had found more copper and was digging deeper, so the equipment had to pump water from further distances,” said Carlos Coll, sales manager for Xylem Water Solutions Peru. “It can rain at any time, day or night, so they had to be ready to go and switch the pump on at any moment.”

With the existing pump switch located deep in the mine, the company had to employ contract workers to travel down into the pit and physically set the control, said Coll. The situation became increasingly risky as the pit was extended deeper, and danger from blasting was another potential hazard. “They were really looking to perform [the pump control] operations remotely,” said Coll.

Xylem’s Flygt electric submersible pumps were initially considered for the job, but after analyzing the site’s electrical limitations, engineers specified three Godwin HL130M Dri-Prime pumps instead. Mounted on trailers, the diesel-powered Godwin pumps eliminated the need to run power cables into the mine, according to Coll.

“Those cables were constantly at risk, and the deeper into the operation the company went, the longer they needed to be,” he said. “With a fuel-driven solution, they didn’t need electricity.”

The HL130M Dri-Prime pump is described as a powerful yet compact unit with flow capabilities to 340 m3/h and discharge heads to 191 m. It features Godwin’s high-pressure oil bath mechanical seal design, which enables dry running for prolonged periods while automatically priming and repriming. The HL130M can handle solids up to 22 mm in diameter, making it an effective choice for both slurry and clean water applications. It is offered with a choice of engine options and also is available in an electric-powered configuration.

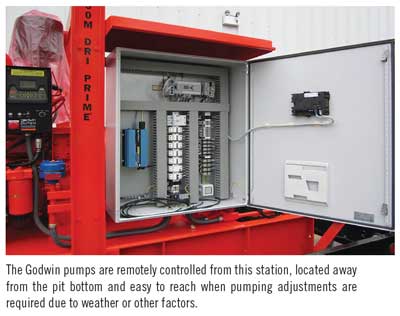

The customer also asked Xylem Peru’s Monitoring and Control Group to provide a solution for remotely controlling the new pumps. The Xylem team designed a system that could remotely start and stop the pumps, monitor capacity and fuel levels, and communicate operating parameters.

To provide the customer with complete monitoring capabilities, the remote system was integrated with the mine’s own SCADA system, with an HMI (human-

machine interface) programmable display on the pump control panel linked to the system, providing a full suite of parameters for equipment control and monitoring data.

With the new system installed, personnel at the mine can control the pumps’ flow and operation in seconds—compared to the original setup in which switching pumps required retrieving the power cable and disconnecting hoses, according to Coll. With the telemetry system designed by Xylem, the mine can quickly adjust the flow when heavy rain events occur.

“The spotlight was on us because it was the first time that this mining company had employed a solution involving end-suction, surface-mounted diesel-driven pumps,” said Coll. “There were a lot of expectations not only from the mine personnel but also mine upper management. Other mining companies in the region were taking notice of the situation as well.”

According to Coll, the business relationship between Xylem and the customer helped successfully implement the system. “We had a strong bond with the customer. Our technicians were there at the mine, working. We trained their employees on the technology and provided the support for them,” said Coll.

The customer has been able to cut costs by eliminating the labor previously needed for manually controlling pumps or running electrical power down into the mine. It is now considering setting up similar pumping arrangements as it expands in Latin America, according to Xylem.

By replacing a mine’s electric pit-dewatering pumps with Godwin diesel-powered units, Xylem was able to reduce the mine’s labor requirements for tending the pumps and their cables deep in the pit.

One Source for Selection

One Source for Selection

Last year, Xylem launched a new website that offers a wide range of information on the company’s dewatering product brands, Flygt and Godwin, on a unified Web platform.

Xylem said the new site (xylem.com/dewatering) presents highly useful content including product, service, parts and application information. It features blogs, site search and mobile compatibility for easy access in the field, and provides country-relevant content based on where the customer is located.

Colin Sabol, senior vice president and president of Xylem’s dewatering business, said, “We know that our customers want an informative self-serve environment to research and explore their options. Based on that premise, the site represents our broad range of products and deep expertise in solving complex challenges. For example, our new ‘Pump Finder’ tool allows customers to quickly narrow to the most appropriate products for specific applications. Customers can also find information on our floodwater drainage to slurry pumping capabilities, as well as the benefits of our rental solutions.”

Additionally, the new online dewatering site features case studies, white papers, ‘how to’ videos and manuals to provide customers with a wide array of engaging reference information relevant to their industry and application. A blog section hosted by Xylem subject matter experts contains educational articles on important regulations such as the U.S. Environmental Protection Agency’s (EPA) Tier 4 diesel-emission standards, as well as repair and maintenance best practice tips.