The $4.2 billion Chuquicamata Underground mine project advances

By Oscar Martínez, Latin American Editor

Located at 2,830 m above sea level in the middle of the Atacama desert, 240 km from the port city of Antofagasta, the Chuquicamata (pronounced choo-kee-ka-mah-ta) copper mine—one of the world’s largest open-pit mines—is transitioning to an underground operation. For its owner, Corporación Nacional del Cobre de Chile (the National Copper Corp. of Chile) or Codelco, the Chuqui Underground project is a massive investment and a significant change in direction for a mine that traces its roots back to 1915. While the challenge is formidable, Codelco is the world’s largest copper mining company and it has vast underground mining experience with its El Teniente (te-nee-en-tay) operation—a block cave mine that was operating 100 years before Chuqui.

Even though the copper deposit was discovered prior to the arrival of the Spaniards, mining didn’t officially begin until the end of the 19th century. Early operations extracted copper from small claims using rudimentary open-pit techniques. Chuquicamata eventually attracted the attention of American engineers and the Guggenheim family, who bought all of the mining rights to the property. In January 1912, the Chile Exploration Co. (Chilex) was founded in New Jersey to develop the Chuquicamata mine. The initial plans for the mine and mill involved drilling and blasting benches, loading ore with steam-powered shovels that were originally used on the Panama Canal, in-pit rail haulage, and ore treatment in a processing plant. The project also included an oil-fired power plant in Tocopilla, the use of the Antofagasta-Bolivia railroad to transport copper to Antofagasta, the use of water from the San Pedro River, and the construction of a mining camp equipped with hospital, schools, markets, and entertainment—all the services required by a mining town nestled in the heart of the desert.

The Chuquicamata mine achieved commercial production in May 1915, reaching an average production of 100,000 tons per year (t/y) of fine copper in the 1920s. Despite all the efforts that were made, the initial results from the mining activities were disappointing in terms of production and profits, which led the Guggenheim family to sell Chuqui to the Anaconda Copper Co. Ltd. in 1923. Anaconda invested more money and significantly increased production, which enabled the mine to operate profitably.

Many advancements were made over the years in parallel with the rest of the mining sector. In 1971, Chile took control of the mine and several others. Today, the Chuquicamata mine is the largest open-pit mine and the second deepest next to Bingham Canyon. And, 100 years later, Codelco is making a massive investment for future generations.

Taking Chuqui Underground

The initial capital allotted for the early development work amounted to $894 million, a little more than 20% of the total capital investment of $4.2 billion. A decision to move forward late last year was approved by the Codelco Board of Directors and officially marked the beginning of the transition of the world’s biggest open pit mine into a large-scale underground operation. In fact, Codelco envisions the new underground mine as one of the biggest, most efficient and most modern operations in the world that will achieve the highest safety and environmental standards.

Nelson Pizarro, chairman of Codelco, recently thanked the board for allocating part of the resources obtained from Codelco’s Capitalization Law to realize this structural project that will help achieve long-term viability for División Chuquicamata.

“We are facing a historic challenge and we have to take it forward on schedule, cost, quality and meeting the highest safety standards,” said Gerhard von Borries, vice president, Chuqui Underground project for Codelco. “To this end, we must develop a very detailed execution plan, work with competent contractors, and implement good control measures to make appropriate decisions.”

The Codelco board also agreed that, within the approval framework for the Chiquicamata Underground project—and keeping in sight that Codelco’s main target is to maximize the value of the company, which provides for the people of Chile—they and their chairman will work on the design and implementation of a conversion and relocation plan for the workers of División Chuquicamata to conciliate, whenever possible, the specific labor requirements aimed at the new underground mine with the strategic objective of caring and cultivating employees competencies, levels of experience, knowledge and skills.

The transformation of the current pit into an underground mine will extend the life of División Chuquicamata at least 40 years. Copper is the life blood for Chile and the Chuqui Underground investment will ensure future revenues for the country and provide employment for thousands of workers.

This mega project will mine part of the reserves lying under the current ore deposit. These reserves have been quantified as 1,760 million tons of ore with 0.7% copper and 502 ppm molybdenum, which would be more than 60% of the ore mined over the last 90 years.

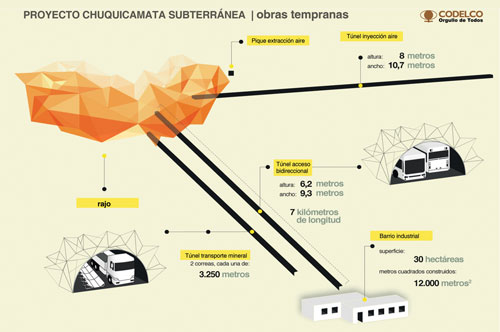

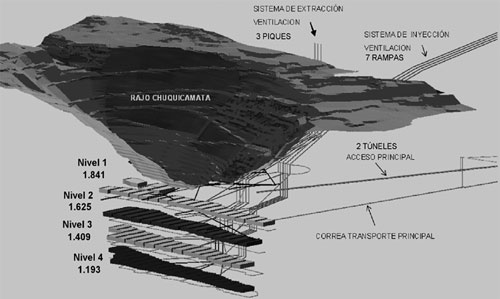

The mine will use the block caving technique, which consists of four production levels, a main access tunnel, five air intake ramps, and two 11-m wide, 918-m deep exhausting ventilation shafts, among many other works. When the mine reaches commercial production, it will produce 140,000 t/d of ore, which will result in a production of 366,000 mt/y of fine copper and more than 18,000 mt/y of molybdenum.

To access and mine the orebody, miners will have to drive 180 km of tunnels. The main haulage for Chuqui Underground is a set of two ramps that are 7,451 m long and it has an average slope of 8.75%. Its design includes deviation areas for place changes every 1,000 m along the entire length of tunnel, and vehicle and pedestrian connections with the ore hauling tunnel that is adjacent to it.

The geometrical design of the tunnel was validated by national and foreign experts, which determined particular operation considerations such as maximum speeds, i.e., ascent rate of 50 km/h for all kind of vehicles, 30 km/h descent rate for service vehicles and 50 km/h descent rate for buses and light vehicles. The speed limits state that all vehicles that enter the mine shall comply with a list of safety requirement that will be checked on a permanent basis.

As for the ventilation system that supplies clean air to the entire network, the access tunnel will have a dedicated vent circuit independent from the one in the mine, with a capacity of 1.2 million cubic feet per minute (cfm). This includes ventilation shafts with their respective fans that inject clean air and draw stale air. It is also equipped with ventilation controls for proper flow and with remote safety and monitoring system.

With respect to safety, the tunnel has built-in closed-circuit television, CO detectors, firefighting systems and emergency intercoms every 50 m; all these are integrated into a control system. There will also be a static and dynamic signage with relevant information for people entering the mine.

The design and construction for these tunnels for operation of underground deposits, ruled by the most stringent safety standards, are a relevant part of the challenges being faced by Codelco nowadays in pursuit of providing resources and knowledge to the state of Chile.

Upon completion of its mine life in 2060, miners will have blasted 1,020 km of tunnels—equivalent to the distance between Santiago and Puerto Montt (a city located in the south of Chile).

An Optimal Changeover

After 100 years of helping the development of Chile, División Chuquicamata has been facing numerous challenges during the last few decades. These challenges, which are normal for a long-life operation, are related to lower ore grades, growing costs and lower production. This complex scenario points to the need to shift to underground mining to access richer reserves at a competitive cost for the company with less environmental impacts.

During the construction phase, the project will provide an average of 6,000 new direct jobs and 18,000 indirect jobs. It will also help to invigorate Chile’s economy through the demand of products and services from some several suppliers and vendors.

Chuqui Underground will be a quantum leap relating to environmental care and respect for the surrounding communities, since underground mining reduces 97% of the emissions of particulate materials and lowers diesel consumption seven fold.

To date, the project is 21% complete and the Gantt chart was being met as planned. The mine is expected to be operating by January 2019.

In additiona to the underground activities, it is important to note that Codelco has signed an agreement to extend the surface operation at the Chuquicamata mine. The company is planning to go ahead with the development of phase 49 down to phase 46 of División Chuquicamata, which is a newly added strategy.

The phase 46/49 splicing [roject is geared to sustain the most profitable option for the changeover from open pit to underground. The focus is on maximizing the corporate surplus from 2015-2020, and recover the competitiveness of the divisional business.

Earlier this year, Chilean Minister of Mining Aurora Williams headed a committee formed by regional and national authorities to visit and learn on site about the project’s progress status. Williams said she was very proud of the work being performed in the tunnels, whose utilization will give productive continuity to Chuquicamata. According to the minister, this mega project is also a global challenge that is being observed by miners from all over the world.

Chuquicamata Underground is without a doubt, a major undertaking for Codelco: Converting Chile’s most emblematic open-pit mine into a world-class high quality underground mine on budget, on schedule, with high safety and health standards, through sustainable development, and respecting the neighboring communities.