By Simon Walker, European Editor

As mines become deeper and hotter, with more diesel-engine vehicles in use, ventilation systems need careful design and tuning. E&MJ looks at some of the opportunities—and the critical need for a responsible approach to fresh air supply.

Diesel-engine equipment underground at Garpenberg, where the installation of an ABB control system brought a 40% cut in ventilation energy costs. (Photo courtesy of Boliden)

Presenting one of the keynote addresses at the 35th International Conference of Safety in Mines Research Institutes, held in London in October, Stewart Bell provided a harrowing account of the Pike River coal mine tragedy in New Zealand in November 2010. Bell, the commissioner for Mine Safety and Health at the Queensland Department of Natural Resources and Mines, was a member of the Royal Commission of Inquiry established by the New Zealand government to investigate the accident and to make recommendations over future practice in terms of both technology and statutory oversight.

In summary, the commission’s findings were shocking. A raft of factors had contributed to the methane explosions that wrecked the new mine and cost 29 lives. And a key contributor to the disaster was the inadequately designed and operated ventilation system.

Coal mines and hard-rock mines both need ventilation networks that provide a sufficient quantity of fresh air, albeit sometimes for different purposes. Typically using more electric-powered equipment, underground coal mining relies on a reliable ventilation stream not only to provide fresh air, but also to remove heat and maintain methane at levels below the 5% lower limit of ignition. Hard-rock mining, in contrast, has more widespread usage of diesel-engine machines, so ventilation systems in this environment have to provide sufficient oxygen for efficient engine performance as well as for removing heat and exhaust fumes. Hard-rock ventilation systems must also be designed to clear blasting fumes quickly and effectively and, as mines get deeper, are increasingly becoming integrated with refrigeration systems that help provide an acceptable working environment for personnel and equipment alike.

According to systems supplier ABB, ventilation can absorb about 30% of an underground mine’s total energy demand. Other experts put the figure even higher. It is easy to see, then, that as energy costs continue to rise, there is increasing interest in being able to tailor ventilation systems to achieve optimal performance at the lowest possible cost—an intricate balancing act between providing a safe working environment and keeping costs under control. As a result, ventilation modeling systems have become increasingly sophisticated, with the ability to design and modify networks, as well as taking external effects such as fires or sudden airflow constrictions into account.

Pike River: Poor Ventilation’s Contribution

In his address to the London conference, Bell said the ventilation system at Pike River was inadequate. The seam being worked was known from long experience in other mines to be gassy, and although the operating company had installed a methane-drainage network, in the event it could not cope with the ingress.

In addition, Bell pointed out, there was a shortfall in the ventilation volume, and although the company had previously been warned of its inadequacy, remediation had yet to take place when the explosions occurred. The situation was such, he said, that a gassy underground mine was being run with no reliable ventilation monitoring, and an official in charge of ventilation who was not qualified to do so.

The Pike River Report (See p.68) identifies some of the issues that the Royal Commission of Inquiry pointed out. In essence, Bell stated, operations at Pike River had degenerated to the point where people had normalized working in dangerous conditions. “If you normalize like this, it will come back and bite you,” he added. And it did.

What is clear from the commission’s report is that poor ventilation was by no means the sole cause of the disaster, but was a significant contributory factor. Had the main fan been on the surface, and had been able to be restarted after the first explosion, the atmosphere in the mine might have been less toxic, and maybe the subsequent blasts would not have occurred.

Diesel Particulates: A Growing Issue

Turning to hard-rock mining, one of the principal areas of increasing concern has been the effect that diesel particulate matter (DPM) can have on human health. There is clearly a link between health and safety on the one hand, and ventilation requirements on the other, with DPM becoming a topic of common discussion at ventilation conferences around the world.

Working in environment, health, safety and training for the mining contractor, Barminco, Sara Fernandez presented a paper on DPM at the Hard Rock Mining Ventilation conference held in Perth, Western Australia, last February. In a pre-conference interview, she pointed out that with diesel having been reclassified as a 1A carcinogen in 2012, this change will drive more interest from mining companies to improve standards.

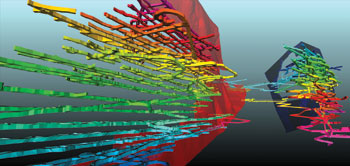

3-D modeling of Tolukuma’s ventilation system using Ventsim software.

3-D modeling of Tolukuma’s ventilation system using Ventsim software.

In 2010, Barminco began a study into DPM to understand the mechanisms and controls associated with its production and distribution in the underground environment.

The company has since built a “whole of operation” management plan for its work sites that brings together the three key issues in managing DPM: ventilation, emissions creation and control, and personal exposure monitoring.

In her conference paper, Fernandez explained that with diesel exhaust comprising a complex mixture of gases and particles, diesel particulate emissions have the potential to cause adverse health effects. DPM behaves similarly to surrounding gases, she said, but has longer residence times in a mine atmosphere. From a personal health point of view, a larger portion of the particulates are deposited in the respiratory tract, with the finest particles (below 1.1 µm in size) penetrating deeply into regions of the human lung.

The current Australian designated safe level for DPM exposure is 0.1 mg/m3, Fernandez said, before presenting some findings from exposure monitoring at underground mines in Western Australia. Nearly 50% of all employees monitored were above the recommended time-weighted average (TWA) of 0.07 mg/m3, she reported, with occupations such as LHD operators, charge-up, jumbo operators, service crew and shift bosses all having more than half of the employees in each category with exposures above the recommended TWA.

Modeling Ventilation Systems

In order to obtain an overview of the current capabilities of ventilation modeling, E&MJ spoke with Craig Stewart, director of the Australian software supplier, Chasm Consulting, which launched version 1.0 of its Ventsim Visual 3-D package in 2009. The latest upgrade, version 3.2, offers a wide range of ventilation design features, he said, including airflow and pressure modeling, heat and humidity prediction, financial analysis and prediction of the best tunnel and shaft sizes, diesel particulate modeling, gas and fire simulation, and radon and dust simulation.

Stewart told E&MJ that the software is designed to accept new and existing mine plans, and then allows the user to build 3-D ventilation plans around the mine design, inserting fans, ventilation controls, diesel equipment and a variety of other devices that influence ventilation. The end result is a model that closely matches the current ventilation conditions underground, he said, and allows future predictions of ventilation conditions and requirements as the mine expands and changes.

According to Stewart, Ventsim Visual is now used by around 1,000 mines in 30 countries, and is available in four languages. In addition, it is used for education in more than 40 universities, and dozens of consulting and research organizations, he said.

One mine that Chasm Consulting assisted using Ventsim Visual was Tolukuma in Papua New Guinea. Everything has to be flown in to this remote gold operation by helicopter, including basic supplies such as diesel.

The ventilation system at Tolukuma was performing poorly, with hot and humid conditions underground, and lengthy clearance times for blasting fumes. Chasm spent several days modeling the mine’s ventilation system in 3-D, with the software showing that large parts of the mine had recirculating air and that fresh air was not reaching its deeper areas efficiently. In addition, the recirculation was causing the slow clearance of blasting fumes. Finally, the software showed that the main primary fans were performing at very low efficiency because of their design.

The software allowed ventilation controls to be theoretically positioned and tested to eliminate the recirculation. In addition, because the diesel-generated power cost at the mine was so high, the software recommended more suitable fans that would save hundreds of thousands of dollars per year in power costs while delivering better airflow. Once the model demonstrated the planned improvements, a plan was put into action to resolve the issues, Stewart told E&MJ.

Recirculation Can Save Energy

At Tolukuma, recirculation was clearly a problem that had to be resolved. In other cases, however, recirculation can be used as an advantage, as Dr. Steven Bluhm and his co-authors described in a paper presented at this year’s Australian Mine Ventilation conference, organized by the AusIMM.

Their paper described the improvements that had been made at Vale’s Taquari underground potash mine in Sergipe state, Brazil. The room-and-pillar mine operates mainly electric continuous miners and shuttle cars, at depths of 450 m–700 m.

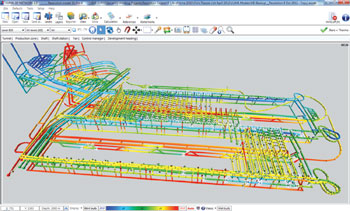

The final model of Resolution’s ventilation system, created using VUMA software. Blue shows areas at 20°C (wet bulb) while red denotes 30°C.

The final model of Resolution’s ventilation system, created using VUMA software. Blue shows areas at 20°C (wet bulb) while red denotes 30°C.

Virgin rock temperatures are high, reaching 50°C at a depth of 700 m, while the relatively small size of the shaft system places constraints on its ventilation-carrying capacity. In consequence, the ventilation system was insufficient to allow the mine to work the full extent of the deposit.

According to Bluhm, CEO of the South African ventilation specialists, BBE Consulting, and his colleagues, the ventilation limitation was overcome by installing two large-scale recirculation systems with underground reconditioning centers. This has been operating safely for some 10 years, while the use of recirculation has been key to both increasing production and extending the workings further from the shafts.

The mine’s ventilation system was modeled using VUMA software to simulate different ventilation, recirculation and refrigeration strategies. The solution that was adopted involves a main recirculation system located near the shaft bases, and what the authors refer to as a “recirculation-within-recirculation” system in the north section of the workings.

They also pointed out that the concept of using recirculation is nothing new, and that a number of large-scale systems are already in operation in South African mines, with return air being scrubbed and cooled in chilled-water spray chambers before being reinjected into the main intake stream. At Taquari, the system now in use satisfies a ventilation duty of 560 kg/s, which is 87% more than the 300 kg/s actually available through the fresh-air downcast shaft.

Earlier this year, VUMA Software released the latest version of its VUMA-3D Network Windows-based package for mine ventilation, cooling and environment control for deep hard-rock mines. VUMA, the company explained, stands for Ventilation of Underground Mine Atmospheres, and was developed specifically to assist with ventilation, heat and dust issues in South Africa’s deep mines.

VUMA Network solves airflow, pollutant, and temperature distributions interactively throughout a ventilation circuit and cooling network. The solution algorithm assumes compressible air and uses complete thermodynamic calculations, the company said, with the package’s solution engine containing specialized modeling algorithms for stopes and development covering narrow reef and massive ore bodies, as well as underground coal mines. The software can be used as a planning tool and as a means of verifying environmental performance parameters in operating mines.

The Challenges Facing Resolution

Bluhm also co-authored another paper presented at the AusIMM conference, held in Adelaide, South Australia, in July. Rather than reporting on a completed project, this looked ahead to the likely ventilation requirements for bringing the huge Resolution copper mine into production.

Lying close to the old Magma mine in southern Arizona, Resolution is currently being evaluated by Rio Tinto and BHP Billiton. Based on a deep, high-grade porphyry deposit, the operation is being planned as a 120,000-mt/d ore producer. Specific challenges include the depth, with the main haulages being more than 2,000 m below surface, the high-virgin rock temperature (more than 80°C) at this depth, and the high silica content of the rock. Current designs envisage the use of electric production loaders and haulage equipment, with diesel machines equipped with the most recent engine technology and above-OEM specification exhaust conditioning.

The authors pointed out that “all diesel vehicles will be operated according to a site-specific, risk-assessed DPM control plan, as well as an emissions-based maintenance program, incorporating regular exhaust testing to identify problems proactively.” The total heat load associated with the mining fleet has been estimated at some 16 MW, with a further 6 MW generated by infrastructure equipment such as fans, refrigerant compressors, crushers and so on. In addition, the heat input to the ventilation circuit from broken rock—around 30 MW—will be very significant.

Again, VUMA software has been used to model the proposed ventilation system for Resolution, indicating that the mine’s needs will be considerably higher than the existing average for other block- or panel-caving operations. In all, the modeling has shown that the mine will need 3,120 kg/s of chilled downcast air, with more than 140 MW of refrigeration capacity in air coolers located both on the surface and underground.

Supplying Ventilation as Required

One way of managing ventilation in a responsive manner is to install an automatic control system that will increase local airflows on an as-needed basis. ABB offers its System 800xA platform for controlling underground ventilation, in addition to applications such as pumps, mine hoists and crushers. The company stated that its mine ventilation system optimizes ventilation energy usage as well as providing fresh air where it is needed, with air flows able to be controlled by systems such as air-quality sensors, time schedules and the presence or absence of vehicles.

Earlier this year, Atlas Copco introduced the option of a Cummins Tier 4i engine for its ST7 Scooptram, in a move aimed at cutting fuel consumption and emissions, leading to a healthier working environment and lower ventilation costs.

Earlier this year, Atlas Copco introduced the option of a Cummins Tier 4i engine for its ST7 Scooptram, in a move aimed at cutting fuel consumption and emissions, leading to a healthier working environment and lower ventilation costs.

ABB gives the example of its control system being used at Boliden’s Kristineberg and Garpenberg mines in Sweden. At Kristineberg, the company produces polymetallic ore from depths of between 800 m and 1,300 m—making it one of the deepest mines in the country. By programming fans to operate at higher volumes only in areas where active operations are taking place, such as mucking stopes, Boliden has been able to optimize the overall mine ventilation flow while reducing ventilation energy costs by some 30%, ABB said.

Each vehicle used underground has a transmitter with a unique identity number, with local fans being controlled according to the individual vehicle’s type and requirements. Where LHDs are involved in mucking, for example, the fans operate at full volume, with a 14-minute overrun to clear residual exhaust fumes, before cutting back automatically to around 25% speed.

Meanwhile, the introduction of ABB’s control system at the new Lappberget section at Garpenberg in 2009 has allowed Boliden to cut its ventilation energy consumption by 40%. In addition, ABB pointed out, the control flexibility means that ventilation in active mucking areas can actually be increased for the time it is needed, meaning that the air quality is better than would otherwise be possible. All in all, the company added, Boliden expected a three-year payback on its investment in the 800xA platform at Garpenberg, achieved through ventilation energy savings and not having to increase its grid demand capacity with the expansion of operations at Lappberget.

Needed: An Integrated Approach

As mines get deeper and ventilation requirements become more complex, mine operators will have to adapt their systems to meet these new demands. One simple solution is to increase the capacity of the main fans. That, however, increases energy consumption, and may not address local issues related to air quality where diesel engines are in use. It may also be the case that the increased flow velocities in both intake and return airways may become unacceptable.

The alternative is to make better use of existing air flows, which is where today’s sophisticated modeling software comes into its own. Not only can these systems model air flows, but also the effects of heat, dust and other contaminants.

Axial-flow main fans at the Kriel coal mine in South Africa. (Photo courtesy of Dr. Steven Bluhm)

Axial-flow main fans at the Kriel coal mine in South Africa. (Photo courtesy of Dr. Steven Bluhm)

Technical developments in diesel-engine design are also key to future ventilation requirements. For example, Volvo Penta stated that its most recent engines for underground mining machines offer an industry-leading ventilation demand of around 30 cfm/hp—the maximum ventilation rate available for a conventional diesel engine. The advent of new scrubber technology will no doubt help reduce DPM emissions even more, the quid pro quo being that mines will need to step up their maintenance to ensure that everything works properly over the life of the machine in question.

Fire is a major hazard in both coal and hard-rock mines. The post-explosion fire at Pike River was only extinguished by using Queensland’s GAG modified jet engine inertization unit at a cost of more than 1 million liters of fuel. Last year’s truck fire underground at Newmont’s Waihi gold mine—coincidentally also in New Zealand—made the headlines as well. Because the fire broke out in the main intake, the ventilation system drew smoke and heat through the workings, although everyone underground was safe in the mine’s refuge chambers.

Ventilation is not something that can be taken for granted. As Bell pointed out in his conference address, there are no shortcuts. Ventilation needs must be understood, with systems designed to handle all of the challenges that a modern mine can throw at them.

E&MJ would like to thank the AusIMM and IQPC for providing access to the proceedings of their respective conferences. IQPC’s 4th Annual Hard Rock Mine Ventilation conference will take place on March 18-19, 2014, in Perth, Western Australia. For more details, see www.mineventilation.com.au.

The Pike River Report: Ventilation Issues

The Royal Commission of Inquiry’s report into the Pike River disaster looked at the various contributory issues and made a series of recommendations in terms of both operating practices and official oversight of coal mining in New Zealand. (The report can be seen in full at http://pikeriver.royalcommission.govt.nz/.) The following are extracts from some of its comments relating to the mine’s ventilation system:

• “A mine ventilation system must provide fresh air throughout the workings, and take return air out of the mine. At Pike River, the intake of fresh air was from the portal, and return air was expelled to the surface up the ventilation shaft.”

• “The original mine plan specified two main fans located on the mountainside next to a ventilation shaft. Two planning changes were made. Pike decided to relocate the fans underground…. Placing a main fan underground in a gassy coal mine was a world first. A ventilation consultant and some Pike staff voiced opposition, but the decision was not reviewed. Putting the fan underground was a major error.”

• “After the explosion, the joint investigation expert panel used computer modeling to establish the ventilation sufficiency at the time of the explosion and found air supply to the inby areas of the mine would have been fragile, particularly in an emergency.”

• “Ventilation consultants advised Pike on an as required basis, but no one at the mine had dedicated responsibility for ventilation management.”

• “The main fan failed in the explosion. It was not explosion protected. A back-up fan at the top of the ventilation shaft was damaged in the explosion and did not automatically start as planned. The ventilation system shut down.”

• “Methane levels at Pike River were managed through the ventilation system and some pre-drainage of the coal seam from inseam boreholes. By April 2010, the [drainage] pipeline could not cope….Gas consultants were engaged and advised that the pipeline required urgent upgrading. As a stopgap measure, methane was ‘free vented’ into the mine’s return airway to be handled by the ventilation system. The upgrade of the drainage pipeline was put on hold and free venting of large volumes of methane continued up to the time of the explosion. Free venting is no longer recognized as normal practice in modern underground coal mines.”

• “Despite its limitations, the monitoring system showed there was a serious methane management problem…information was not properly assessed and the response to warning signs of an explosion risk was inadequate.”

The report’s recommendations included:

• “Placing main ventilation fans underground in coal mines should be specifically prohibited. It is unlikely that a mining company would do so in the future, given the consequences at Pike River, but the matter should be put beyond all doubt. Main fans should be required to be protected against explosion and other hazards, in accordance with appropriate international standards.”

• “In addition to requiring a ventilation officer, standards for ventilation control devices, such as stoppings that control airflow, need to be specified.”

• “Minimum requirements for gas monitoring systems are needed so that the mine’s atmosphere can be continually and comprehensively analyzed.”