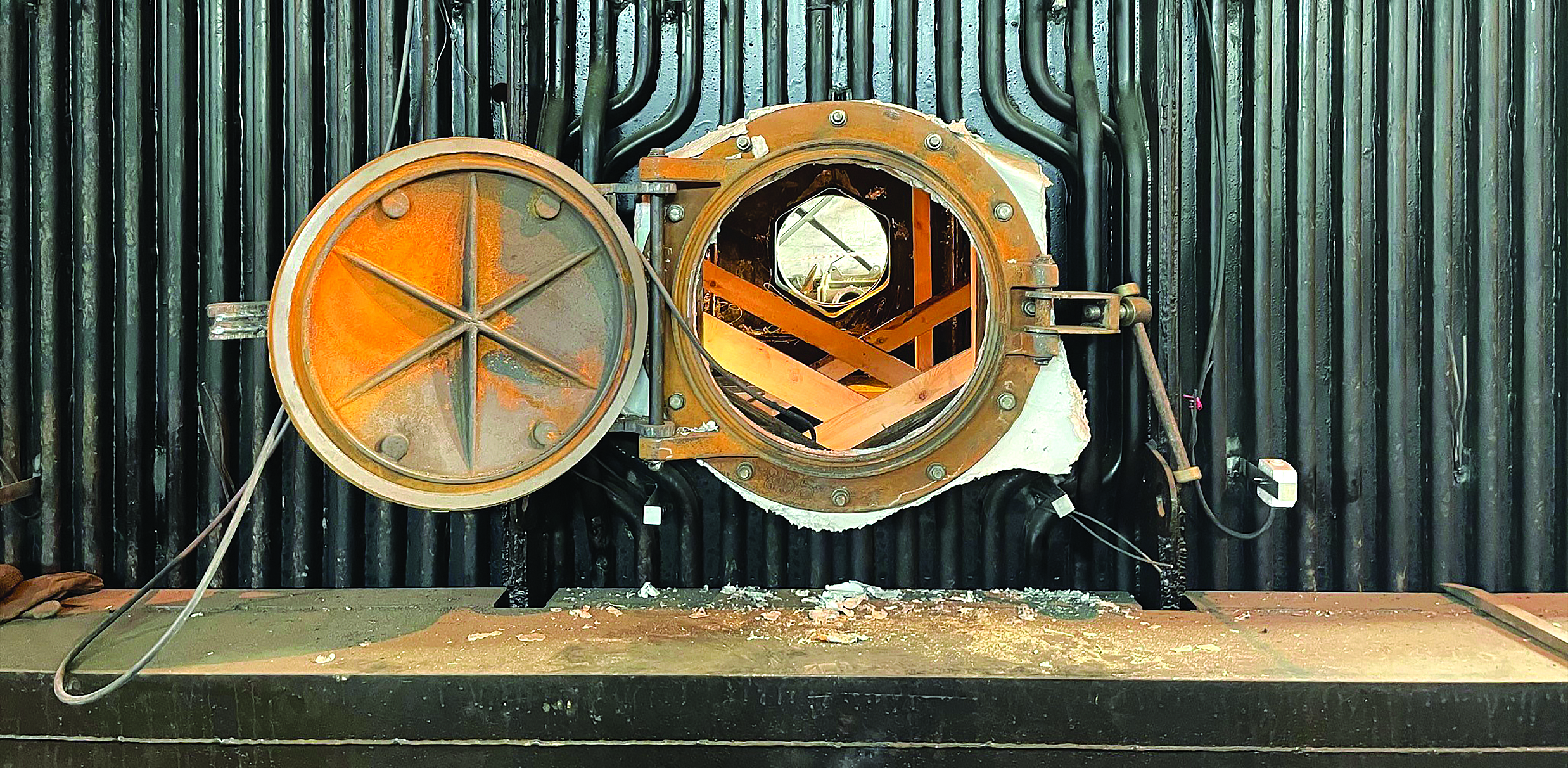

A copper smelter in central Russia that began operating in the 1940s has been modernized several times and currently runs two copper flash smelting furnaces. The plant can produce up to 150,000 metric tons (mt) of copper matte per year, and management has ambitious plans for improvement. Standing in the way, however, was a problem: Flue gas temperature inside boilers situated directly above the furnaces’ uptake reaches 1,350°C/2,462°F, causing rapid metal erosion and slagging. Slag could not be removed manually due to access issues, and water leakage into the furnaces was a constant risk.

A copper smelter in central Russia that began operating in the 1940s has been modernized several times and currently runs two copper flash smelting furnaces. The plant can produce up to 150,000 metric tons (mt) of copper matte per year, and management has ambitious plans for improvement. Standing in the way, however, was a problem: Flue gas temperature inside boilers situated directly above the furnaces’ uptake reaches 1,350°C/2,462°F, causing rapid metal erosion and slagging. Slag could not be removed manually due to access issues, and water leakage into the furnaces was a constant risk.

In search of a solution, the customer turned to Integrated Global Services (IGS), an international provider of surface protection solutions headquartered in Virginia, USA. IGS claims to have more than 35 years of experience helping customers solve metal wastage and reliability problems in mission-critical equipment involving corrosion and erosion problems in challenging operating environments.

IGS said its High Velocity Thermal Spray HVTS solution upgrades existing metallurgy to higher alloys that provide a barrier to mitigate corrosion and/or erosion. The company said it has performed more than 4,000 site projects and installed millions of square feet of reliable metal cladding surface protection. Among the benefits gained by the smelter customer are:

• Deslagging has vastly improved. During monthly inspections of the boiler following HVTS treatment, no slagging has been detected on the boiler wall. The efficiency improvement increased production in 2020 to 112% of design capacity.

• The IGS HVTS application prevented the degradation of the heat recovery steam generator, which previously lasted only 24 months.

• Reliability has improved as well. Prior to the IGS HVTS application, the plant frequently had to perform emergency localized shell repairs.

As a result of these improvements, IGS said the customer now includes HVTS technology in its best practices list. They plan to install IGS surface technologies on to refractory surfaces and convection section coils to eliminate slagging and increase the production rate.