Polypipe, one of Europe’s largest manufacturers of plastic piping systems, is set to expand its presence in the African market. The company is focusing on the mining industry in the region, having already secured contracts to supply pipework systems to major projects in Kenya and Sierra Leone.

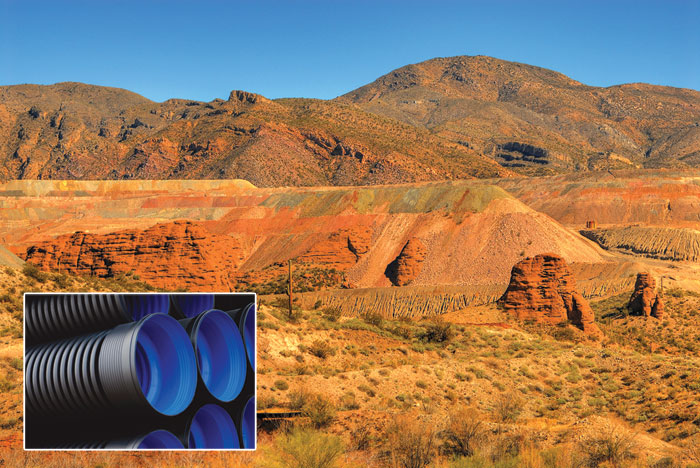

Polypipe says its Rigidrain (shown here) and PE100 pipe systems will be particularly useful in the African market, having been used in tough mining environments for drainage and in applications such as recirculation pipelines for heap leaching operations, solution mining, process slurry pipelines and process water.

Polypipe said it is able to offer pipework and water management systems to meet the needs of mining operations themselves, which involve both pressurized pumping and gravity systems, mining process pipework, and all of the water supply and drainage involved in the construction of buildings, offices and accommodation complexes.

According to the company, one of its key product systems for this sector is PE100, a high-density polyethylene pressure pipe system that has been used in some of the toughest mining environments in applications such as recirculation pipelines for heap leaching operations, solution mining, process slurry pipelines and process water. Chemical and corrosion-resistant, Polypipe claims it can cope with harsh materials from abrasive slurries to corrosive acids, bases and salts, offering excellent hydraulic properties and enabling large volumes of liquid to be carried at high-flow rates—while resisting scaling, biological buildup and damage through thermal shock. Pipes and fittings can be jointed using electro-fusion or butt-welding techniques.

Of equal importance in mining applications, said the company, is the Polypipe Ridgidrain twin-walled pipe system, which is suitable for non-pressurized storm water, sub-surface gravity drainage and offers a number of advantages over traditional pipe systems. In underground installations, Polypipe twin-wall pipes will accommodate ground movement and subsequent settlement after installation without failure. Twin-wall pipes are available from 100 mm to 2,100 mm in diameter.

Polypipe’s export manager, Philip Wood, said, “One of the key advantages of the Polypipe Ridgidrain and RidgistormXL system is that it has excellent environmental credentials. The product has a high recycled plastic content and requires less energy to manufacture than other materials. It is up to 94% lighter than traditional concrete systems, making it easier to handle, which in turn considerably reduces transportation and ‘on-site’ plant hire costs. When shipping the product overseas, Polypipe can maximize the sea container space by carrying pipes within pipes. This means that considerably more meterage can be loaded into one container—an important consideration when shipping pipes worldwide.”