|

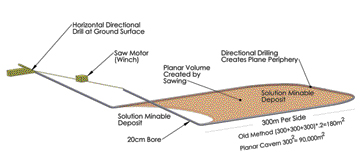

| Diagram illustrates a novel method for creating a planar cavern to improve solution mine performance. |

A recently developed technology de-signed to increase the wetted area of a bored solution mine by two orders of magnitude has the potential to drastically reduce capital investment requirements, speed up rate of return on investment, and make previously deferred deposits potentially profitable, according to Steve Wentworth and Samuel T. Ariaratnam, business partners in an enterprise focused on facilitating the migration of “trenchless technology” to applications in mining. The new technology, Wentworth told E&MJ, is aimed at applying trenchless principles to the field of mineral extraction, eliminating risks arising from human involvement in the process. Potash and/or lithium extraction are likely areas of application.

Ariaratnam—a professor in the Del E. Webb School of Construction at Arizona State University and a past chairman of the International Society of Trenchless Technology—and Wentworth explained that solution mining of evaporates such as potash and other salts stands to benefit from capability advances in horizontal directional drilling. Given the recently achieved ability to intersect or join aligned bores, it is now feasible to produce a three-sided periphery within a desired deposit horizon. By performing a secondary operation to expose a planar surface whose edges are defined by this periphery to solvent, the area and, therefore, the volume of pregnant brine produced are more than an order of magnitude greater than that derived by conventional solution mining or even novel horizontal directional drilling enhanced solution mining methods.

The developers claim that by creating a sizable plane of exposure to the solute, the rate at which the target mineral changes from solid to solution is orders of magnitude greater than existing cutting-edge techniques. Applying their patented process, titled, Method and Apparatus for Creating a Planar Cavern (U.S. 8,646,846), deposits that are marginal for development may well be extracted quickly and profitably, even when the horizon vertical thickness is minimal. Further, capital investment requirements may be reasonable and appropriate for fields previously passed over. And, because the method can produce pregnant brine in high volume and within weeks of completion of the secondary operation, time to return on investment may be optimal when compared against other solution mining methods.

For more information, contact Went-worth at sansaman@cox.net.