|

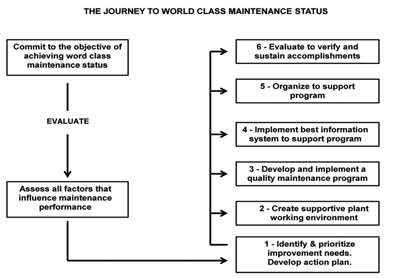

| Figure 1 – After evaluating current maintenance performance: (1) Identify improvement needs and their priorities to develop an action plan. (2) Create a supportive plant working environment to ensure support and cooperation from other departments. (3) Develop and implement a quality maintenance program. (4) Based on the actions required in the program, select and implement the best information system to support the program. (5) The program prescribes the what, how, who, when and why to carry out maintenance services properly. Using these guidelines, implement the type of organization that can best meet the program requirements. (6) Evaluate again to verify that improvement needs established in (1) have been achieved and that they can be sustained. |

Numerous worthwhile benefits accrue to the industrial organization that is supported by a maintenance organization performing at the world-class level. That organization will be favored with consistently reliable production equipment. They will be assured of meeting production goals. Their product will exceed marketplace standards. Their customers will see them as a quality organization. Their employees will enjoy job satisfaction, and the plant will realize continuing profitability.

Every industrial installation aspires to “world-class” status knowing they can compete favorably with the best, most profitable organizations in the world. The trick is to achieve the attributes that qualify the organization for world-class status. But there are no world-class maintenance organizations. Rather, there are world-class industrial organizations that include a world-class maintenance organization. Maintenance, by itself, is a service provider dependent on the support and cooperation of other departments. When that service is exceptional, it is made that way because maintenance is operating in an environment that requires it to be exceptional. Managers have created an environment in which maintenance can be exceptional. The plant, mine or facility manager must acknowledge from the start that maintenance is not a “stand-alone” effort of a maintenance department. It will require the joint efforts of all plant departments. Quality material support and full cooperation from operations, for example, are among the essential requisites for effective maintenance and achievement of world-class maintenance status. When attributes such as these are reinforced by dedicated plant managers, profitability soon follows.

Making the journey to world-class maintenance status is a six-phase process.

Start with an Evaluation

The first step of any improvement effort, and the journey to world-class maintenance, is an evaluation to identify improvement needs and their priorities. Only then can a meaningful improvement effort be launched. An evaluation is the first step of improving maintenance. It is the road map of the journey to world-class maintenance. It is the plan of action for accomplishing needed improvements. Without an initial evaluation, the improvement effort lacks direction and purpose. When improvement needs are based on guesswork rather than a solid evaluation, the results are invariably frustration, confusion and no improvement. When an evaluation determines the factual improvement needs, the resulting action plan is realistic and attainable (see Figure 1).

Assure Effective Support for Maintenance

As the world-class journey starts, create a positive maintenance working environment to assure full cooperation and support by all plant departments with strong plant management reinforcement. With the realization that the entire plant (or mine) is behind them, maintenance commences the journey with purpose and enthusiasm.

Progression toward world-class maintenance is unlikely to be made unless plant managers get heavily involved from the outset. When plant managers, for example, have a production strategy spelling out the mutually supporting responsibilities of each department in support of maintenance, this is a good start. If they have policies specifying how departments are to interact in support of the production strategy, even better. If they require all departments to produce a solid program specifying and documenting internal and interdepartmental actions, the journey to world-class maintenance has a good chance of being successful. The active participation of plant managers is vital.

|

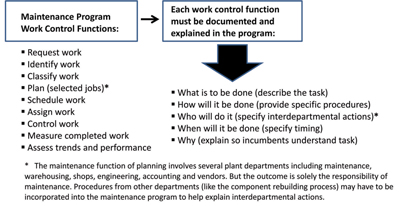

| Figure 2 – It can never be assumed that all maintenance personnel understand every aspect of their program, nor can it be assumed that every plant department understands how they can most effectively support the maintenance effort. The only way to avoid the potential disaster of misunderstanding, guesswork, or sheer omission is to ensure that all aspects of maintenance are understood across the entire operation by educating the total plant population on the details of the maintenance program. |

Map the Journey with a Quality Maintenance Program

The maintenance purpose is soon manifested in the development, documentation, testing and implementation of a quality maintenance program. The program spells out how work is requested, identified, classified, planned, scheduled, assigned, controlled, measured, and, subsequently, trends and performance assessed to guide essential improvement. The details of what maintenance does, who does what, how and why are prescribed by the program. No maintenance function can be carried out without the support and cooperation of other plant departments. The maintenance function of planning, for example, requires the support of warehousing, purchasing, shops, engineering, vendors and accounting. Yet, the outcome is exclusively a maintenance responsibility. But the most important aspect of the program is the education of the total plant population on its details. Supporting roles are clarified. Departmental interactions are confirmed. The whole plant now moves forward in a mutually supporting, fully cooperative effort to ensure that maintenance contributes to overall plant performance with consistently reliable equipment. Program details also guide the choice of the best organization to carry out the program and the best information system to support it. Remember: If help is needed, it begins by telling helpers how to help. No tell—no help (see Figure 2).

Control the Journey

Navigation of the route to world-class maintenance is guided with a quality information system. That system is the communications network to control work and manage the program itself while working effectively with other departments. Fully integrated systems linking department activities with accounting are most common. The accompanying maintenance work order system must be easy to use and produce useful, accurate and timely decision-making information. Quality information manages the program, controls work and guides interdepartmental actions while keeping plant management informed. Thus, support for maintenance is better assured and provided willingly and correctly. The best information system is neither the most expensive nor the most highly touted. Rather, it is the one that matches the information requirements of a well-defined maintenance program.

Who Does What?

As the journey continues, the maintenance program supported by a quality information system requires an organization to bring it to life. Since the program prescribes what maintenance does, who does what, how and why, it also provides the necessary guidelines for the selection of the best maintenance organization to carry out the program. Any maintenance organization that is faltering or ineffective can usually attribute their plight to a failure to develop, document and implement a quality maintenance program. The absence of a program invariably results in confusion within maintenance, as each person has a different “folklore” outlook on what should be a standard procedure. Departments know that they must support and cooperate with maintenance, but, with no program to guide them, they guess at what they are to do. The result is often no help or the wrong help.

Confirm Arrival

When the journey approaches the world-class destination, the evaluation process should be reapplied to confirm that all improvement needs established in the initial evaluation have been met. The evaluation process has helped to measure progress and achievement during the journey. It has proven itself. It should be incorporated into the plant’s continuous improvement effort to ensure that world-class achievements are sustained.

Paul Tomlingson is a Denver, Colorado-based consultant who has dedicated his career to helping miners improve maintenance programs. He has written more than a dozen articles for both Coal Age and Engineering & Mining journal (E&MJ) starting in 1980. He has recently revised the previous two editions of his textbook, Equipment Management. He can be reached at pdtmtc@msn.com and www.tomlingson.com.