The Los Pelambres copper operation, 60% owned by Antofagasta Minerals, is one of the world’s largest copper mines. It sits at an elevation of more than 3,000 m (9,800 ft) in the Andes range, 240 km northeast of Santiago.

After encountering unanticipated problems from a newly implemented fast-refill fuel system for its haul trucks, the mine resolved those issues and gained additional benefits by installing a monitoring system that accurately reports and records truck fuel-tank status.

Los Pelambres’ 55 Komatsu haul trucks are a critical element of mine production. As part of an effort to maximize asset utilization, the mine adopted a fast refueling system for the trucks that would reduce refueling time from 25 to approximately 5 minutes. However, this initiative produced an unexpected series of issues that offset the intended goal—specifically, the mine was seeing frequent rupture of factory-installed fuel sensors due to high pressure from the refueling system. Without a working fuel sensor, drivers had to guess when it was the right time to refuel and could only estimate how much fuel would be needed to top off the truck’s tank.

Not surprisingly, guessing rarely paid off. Drivers sometimes waited too long to refuel and the tank went empty, causing air to leak in. Purging the air added five additional hours to the refueling process. Overall, tanks were filled to maximum capacity only 0.6% of the time, which ended up significantly increasing the number of refueling stops. Because no one could optimize the refueling schedule, drivers often reported to the same refueling center at the same time, which caused long lines and delays.

These issues and the ensuing consequences not only undercut the intended benefits of adopting the new refueling method; they actually increased downtime and negatively impacted revenue at the mining site. To address the problems created by the fast refueling system, Los Pelambres invited a group of companies to submit a proposal for a solution that would:

- Equip the trucks with a ruggedized fuel sensor that would withstand the pressure from the fast refueling system.

- Relay fuel level and truck location data back to a centralized application over cellular or satellite depending on network availability to ensure uninterrupted connectivity.

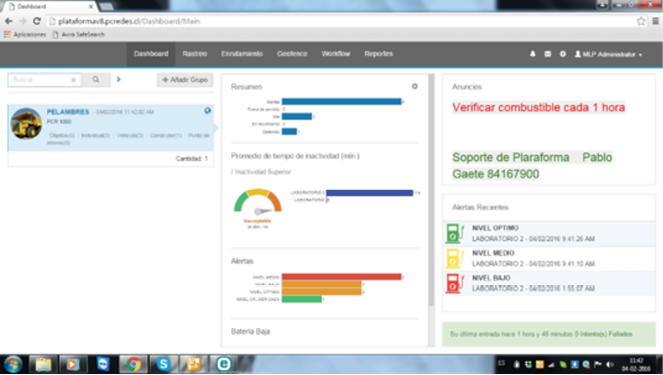

- Include an application with a user-friendly graphical interface that would display the position of trucks as well as tank levels in real-time. The application would also allow the control center to monitor alarms based on user-defined thresholds.

The monitoring system installed at Los Pelambres uses Orbcomm’s Skywave IDP-782 data terminal to transmit fuel-status information over cellular or satellite networks.

The solution selected for Los Pelambres was developed by Tarco LTDA, a Chilean integrator specializing in developing custom tracking and monitoring solutions for the mining industry. The PCR 1000—Tarco’s state-of-the-art remote fuel monitoring system—constantly monitors tank levels and transmits tank-level data as well as other vehicle telematics data back to a centralized application in real-time using Orbcomm’s SkyWave IDP-782 terminal. Since mining trucks operate in remote areas, satellite connectivity is a must to ensure timely and consistent data delivery. The SkyWave IDP-782 transmits data over the cellular network when available and automatically switches to the IsatData Pro satellite data service when cellular is down for uninterrupted connectivity. The ruggedized fuel monitoring system is capable of withstanding extreme environmental conditions, including heat, cold, water, dust, altitude and vibration.

To solve the refueling issues, Orbcomm’s SkyWave IDP-782 dual-mode terminal continuously collects, processes and transmits data from the truck’s fuel sensor. When it comes to managing alarms, the terminal is programmed to identify user-defined thresholds and send only relevant information over the air to minimize data transmission costs. The PCR 1000 remote fuel monitoring system gives the control center complete visibility into refueling operations and an easy-to-use interface that displays truck location and tank level in real-time.

The control center’s operator is able to easily identify trucks with 10% fill levels and quickly dispatch the driver to the most efficient refueling center. Historical data and advanced reports are also available to help operators identify fuel consumption patterns and implement more efficient refueling practices.

By implementing the PCR 1000 remote fuel level monitoring system, an additional 1,200 liters of fuel can be added to the tanks at each refueling stop. This reduces the number of stops per month by 10 for each truck and adds approximately four additional hours of work time over the same period. During this time, trucks are able to haul an additional 4,000 tons of copper, which has had a significant impact on the company’s bottom line.

Los Pelambres’ centralized approach to the refueling process provides greater visibility into the trucks, improves efficiencies and maximizes profitability. According to Pablo Gonzalez, EDT manager–Product Support Group for Komatsu South America, the PCR 1000 is a viable alternative for managing the refueling process as it seamlessly attaches to the trucks’ tanks without imposing any risks or limitations on their operation.

Historical data and comprehensive reports generated by a state-of-the-art remote fuel monitoring system indicate fuel consumption patterns to help users implement improved refueling practices.

Furthermore, the vehicle telematics data collected and transmitted via the SkyWave IDP-782 provides a way to streamline service scheduling and support preventative maintenance practices. This helps prolong the life of the vehicle by reducing wear and tear and ultimately translates into operational savings.

The solution also supplies valuable data for asset utilization. Upon analysis, mine operators were able to identify that the same amount of ore could be transported with fewer trucks. And, because operational costs are quite high for each truck, this provided a way to improve the company’s bottom line.

Orbcomm Inc. is a global provider of Machine-to-Machine (M2M) communication solutions and operates a commercial satellite network dedicated to M2M.

North American Palladium’s Lac des Iles underground mine cut production blasting costs by 5% after switching to Dyno Nobel’s DigiShot blast initiation system. (Photo: NAP)

Bigger Blasts Lead to Lower Costs With DigiShot Plus

Commercial explosives supplier Dyno Nobel reported that it recently implemented its DigiShot Plus Electronic Initiation System at two underground mining sites, yielding results that increased productivity, improved safety and decreased overall production costs. The two underground mines, both located in Canada, were interested in improving overall productivity by using larger-scale blasts—a job well-suited for Dyno Nobel’s DigiShot Plus system, which can dependably fire a large number of detonators and can be used remotely from the surface in underground mines. One of the mines experienced a 5% reduction in cost because DigiShot Plus improved fragmentation and eliminated the need to re-blast oversize material. At the same mine, larger blasts also allowed it to benefit by cutting setup time up by 10%–15%. The need for less-frequent blasting enabled the mine to utilize its production crews more efficiently.

That mine, North American Palladium’s Lac des Iles operation located 90 km northwest of Thunder Bay, Ontario, wanted to expand its underground operations and increase its underground production rates. The mine opted to switch to Dyno Nobel’s DigiShot Plus electronic initiation system for all of its production blasting.

The Lac des Iles mine began production as an open pit in 1993 and went underground in 2006. In late 2010, the company began an expansion of the underground mine to access a new mineralized zone, and to transition operations from ramp haulage to shaft haulage. Mining at Lac des Iles is by longhole stoping, with blastholes approaching 50 m (164 ft) in depth. The type of blasting the mine desired required a system based on an electronic detonator with a high tensile strength downline wire, precise delays, and flexibility both in terms of allowable number of detonators in any given blast and blast duration.

DigiShot Plus, according to Dyno Nobel, met the mine’s tough downhole requirements providing an easy-to-use system with minimal components both underground and on surface, allowing users to conveniently tie-in blasts and assign delays. The DigiShot Plus electronic system uses a double-insulated down-line wire capable of withstanding tough loading conditions. It has water-resistant connectors, which provide a physical link for two-way communication. This two-way communication connects with each detonator’s electronic chip, allowing testability both locally and remotely.

DigiShot Plus allows for up to 7,200 detonators to be fired in one to four blast locations with a blast life lasting up to 20 seconds. It also uses software that allows users to assign delays prior to loading for a quick tie-in at the base site. The system is capable of remote firing from the surface due to its capability to communicate via leaky feeder—eliminating the need to run additional lead wire, saving both time and money.

After adopting the DigiShot Plus system, the mine reported several benefits, including:

- Improved loading efficiency, leading to significantly improved fragmentation while reducing the need to re-blast oversize, resulting in a cost reduction of about 5% in production blasting.

- The ability to employ much larger blasts, cutting the number of blasts needed overall and thus allowing the mine to benefit from economies of scale, reducing production blasting costs by 10%–15%.

- Simple tie-in and connection, reducing production blast setup time by 5%–10%.