From clean diesel engine technologies to electrification, fuel cells and synthetic fuels, Rolls-Royce is on a mission to power mines more sustainably

With its MTU engines and systems, Rolls-Royce has an impressive track record, and not just in the mining business; the company’s systems power some of the world’s largest yachts, strongest tugboats and biggest land vehicles, as well as providing energy for some the world’s most important mission-critical applications.

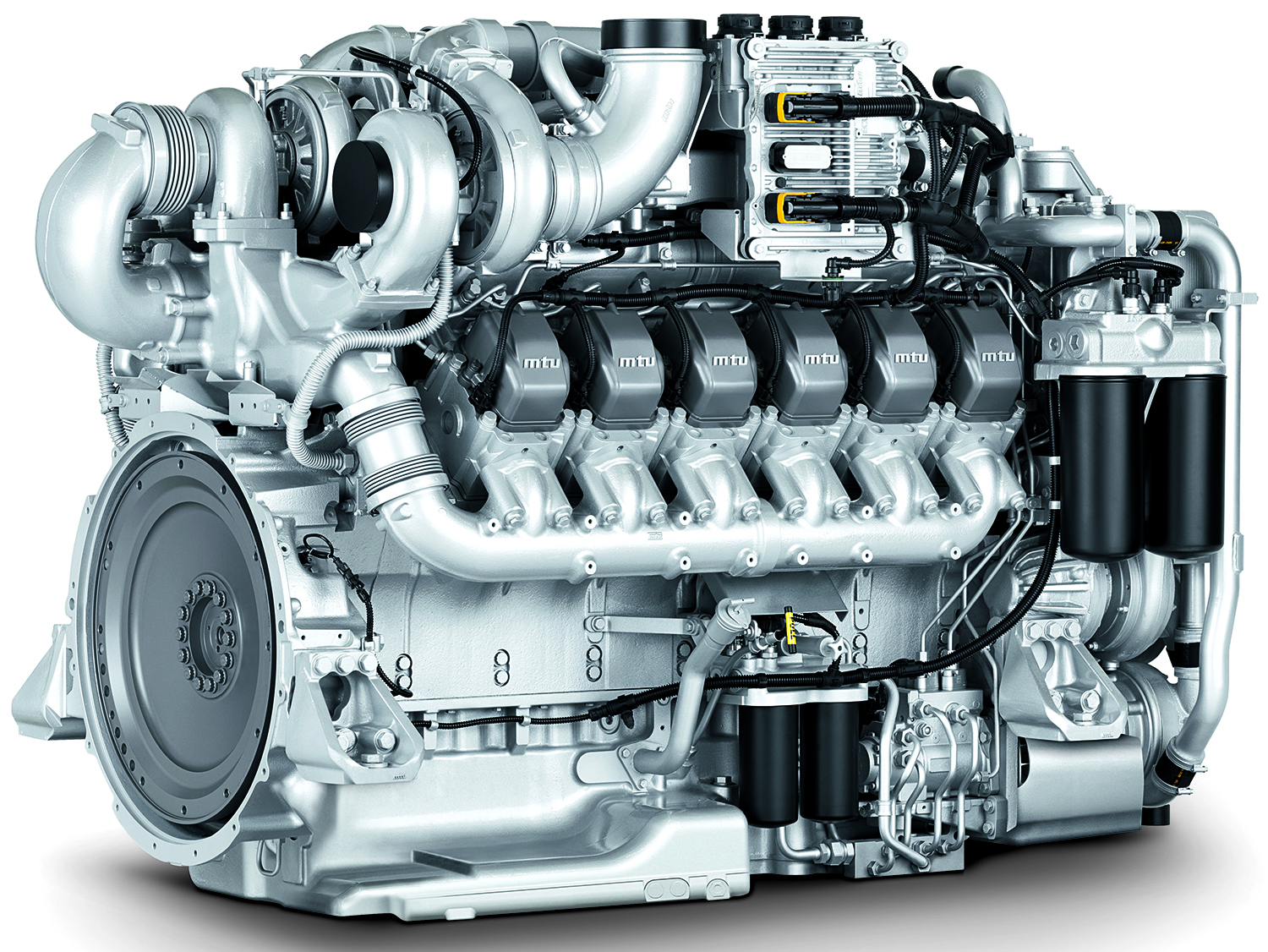

“We’ve been delivering drive and power solutions to our mining customers for decades,” said Sven Kohout, senior manager for mining, EMEA. “Our Series 4000 MTU engines are the benchmark for powering mining trucks since 1996. For example, it was the very first engine with common rail injection technology worldwide in any application.

“When we brought this technology to the mining industry, the engines of our Detroit Diesel product range had already proven themselves in these applications. We knew exactly what was needed to meet our customer’s demand: drive and power solutions with a high-power density and extreme reliability which combine economic efficiency with environmental sustainability.”

The MTU brand has been part of the Rolls-Royce engineering group for more than five years now. It is the solutions brand of the company’s Power Systems business unit — the second largest business unit within Rolls-Royce. Having settled into the group well, some rebranding is now afoot. The Power Systems business unit, with its solutions brand MTU, is now presenting itself more clearly as an integral part of Rolls-Royce.

One of the first steps will be the renaming of operating companies that manufacture products and solutions: MTU Friedrichshafen GmbH will thus become Rolls-Royce Solutions GmbH, for example.

Kohout said the new brand architecture will provide clarity and improve the recognition of the company and its products.

“Our new profile is a clear commitment to Rolls-Royce,” he explained. “By the same token, Rolls-Royce is committed to our MTU brand, which is something we are proud of.”

From New Power to Re-power

MTU Series 4000, 2000, 60 and 900 engines are applicable to mining trucks, excavators, wheel loaders and rock drills.

“We feel our solutions for the Tier 4 final emissions regulations give us an edge over our competitors,” Kohout said. “We fulfil these regulations without any external aftertreatment, using four key engine technologies:

• Cooled high-pressure exhaust gas recirculation (EGR);

• Regulated two-stage turbocharging;

• Common rail fuel injection; and

• Advanced diesel engine controller (ADEC).

“The engines of all our competitors depend on add-on aftertreatment solutions such as SCR systems, diesel oxidation catalysts and, in some cases, additional diesel particulate filters.”

Kohout said MTU technology allows customers to operate their equipment without the need for additional infrastructure or complicated regeneration strategies which might interfere with their operational schedules. The technology has also made the engines even more environmentally friendly and efficient: they use less fuel while at the same time delivering more power which makes them ideal for challenging jobs including those at high-altitude mines.

“Tier 4 final technology is now a must in the U.S., but also, in other countries, mine operators are increasingly introducing these solutions of their own initiative, for example in Chile,” Kohout said of the growing interest in green engine technologies.

Another important market that Rolls-Royce has been successfully targeting is repowering mining equipment.

Kohout explained: “By repowering we mean replacing the original non-MTU engine in a machine with one of our own solutions. This typically happens when the first engine reaches its end-of-life. The total machine life typically is three times the lifetime of an engine.

“This allows us to address a part of the market that is not open to us initially, because some OEMs do not offer MTU as an engine option in new-built trucks. The technical challenge for us in such cases is that there is typically no support by the OEM and no technical documentation available. Here our engineering capabilities play a decisive role as they allow us to do reverse engineering, e.g. creating drawings by measuring the real machine.”

During OEM projects, MTU offers engine installation support for customers, including trainings, written documentation and personal consultancy. When the machine prototype is ready, it offers engine commissioning and installation testing. And, if any problems arise, the company can help with failure analysis and design improvement advise.

Going Off Grid

Rolls-Royce is also expanding its portfolio of MTU energy systems with the addition of microgrids for mines.

“With these we offer mine operators a sustainable energy supply system that can be operated in remote regions independently of public power grids,” Kohout explained. “Our solutions combine renewable energy sources with an MTU battery storage system and MTU diesel and/or gas generator sets. A central controller ensures that the mine’s entire demand for electricity is made available in a reliable and efficient manner, and one that is friendly to the environment.”

For mine operators, energy costs are a key factor because they account, on average, for 15% of overall mine operating costs. And with each mine requiring around 50 to 100 MW of electricity, sustainability, efficiency and reliability of energy supply is becoming increasingly important to the industry. By integrating renewable energy and smart networking of components into their power supply, mines can realize a significant reduction in fuel, as well as eliminating the costs associated with connecting to local power grids.

“Besides MTU generators, our microgrid solution includes battery containers combined with photovoltaic and wind power plants in autonomous power grids. All the components are connected to each other via a smart energy management system, which optimizes the way in which the energy is used both technically and commercially,” Kohout said.

“Any excess renewable energy can be stored in the batteries and then made available whenever it is needed. At the same time, fluctuations in power generated from renewable energy sources due to weather conditions and the time of day are compensated for with reliable diesel and gas generator sets, in addition to battery storage systems.”

The MTU system is thus designed to provide a stable power supply at all times, even when the demand for electric power is high and when systems are required to operate around the clock.

Diesel Engines: Here to Stay — as Part of Advanced Systems Technology

There are a lot of misconceptions surrounding diesel engines at present. They are often seen as dirty and polluting, not part of the drive towards green technologies, but this is not necessarily the case.

“We believe that the combustion engine still has a bright future,” said Kohout, definitively. “We are developing ever more environmentally friendly MTU engines. Their reliability and high-power density are indispensable for many demanding applications.

“In the near future these engines will possibly no longer be the sole source of drive and power energy, but they will still play an important role as part of advanced systems technology. We already offer hybrid rail drives and marine propulsion solutions. The first trains with MTU Hybrid PowerPacks will enter service this year — comparable technology could in general also be an option for the mining industry.”

In most applications, the energy density of batteries is still no match for that of diesel fuel so it is unrealistic that the combustion engine will become obsolete on short notice. However, that does not mean that the combustion engine cannot be made climate-neutral. Synthetic fuels made from captured CO2 with the use of electricity from renewable sources may play a salient role in that regard.

“We are investing in this technology and researching it with several partners from industry and science,” Kohout said. “Examples include the ‘Methquest’ project, which is funded by the German federal government.”

Rolls-Royce is one of the joint lead project coordinators for Methquest in which 27 scientific, industrial and business partners are collaborating on research and development work over a period of three years. The project’s goal is to develop and analyse technologies that will enable methane-based fuels from renewables to be used in mobile and stationary applications, and subsequently launched on the market.

Kohout continued: “In addition, we support research into green fuels in the Lausitz region of eastern Germany together with the state of Brandenburg, Brandenburg University of Technology Cottbus and other industrial partners such as BASF and Lufthansa.

“And electrification of our drive systems and synthetic fuels are not the only technologies we have in mind for the future…”

An MTU battery container as part of a microgrid. Microgrids are essential to decentralized power supply and are particularly important for remote mine sites.

From Fuel Cells to Synthetic Fuels

Rolls-Royce recently started an exciting fuel cell project with partner Mercedes-Benz AG to adapt fuel cell technologies for use in off-grid critical power applications; a technology that could eventually benefit companies in the mining sector, too.

“We have taken the first step in the direction of using vehicle fuel cells for stationary power generation together with Lab1886, an innovation lab within the Mercedes-Benz group,” Kohout explained. “In a pilot project, Rolls-Royce will develop an integrated MTU solution for sustainable off-grid generation of continuous and emergency power using vehicle fuel cells, focused on safety-critical applications.”

MTU generator sets are already in service at numerous mission-critical sites worldwide, providing emergency power when needed. To date, these generator sets have been diesel-engine based, but fuel cells could be a valid alternative. The pilot project will begin in early 2020 and will include the construction of an emergency power plant for Rolls-Royce’s site in Friedrichshafen.

The plant will be based on fuel cell modules built by Mercedes-Benz Fuel Cell GmbH. Mercedes-Benz has developed expertise in hydrogen-powered electric vehicles through its work in the automotive sector, while Rolls-Royce has long-standing experience of fuel cell systems using other technologies.

Key to Rolls-Royce’s long-term vision is the company’s PS 2030 business strategy. This is multifaceted and designed to ensure the company’s future in a rapidly changing world.

Kohout explained that PS 2030 is made up of three main components: strengthening the company’s core business, while at the same time transforming it into a provider of integrated solutions. And, thirdly, developing new digital products to open a new dimension of service for customers.

“The combustion engine continues to be a central element of our business,” Kohout said.

“But to continue our success into the future, we cannot rely on our core business only, we also have to tap into new markets and technologies. In addition to diesel engines, we are thus increasingly focusing on environmentally friendly hybrid, electric and LNG power delivery systems.”