Using the ISCR well field above for the Production Test Facility, Florence Copper extracts more than 1 million lb of copper.

As final permitting stage approaches, purchases of long-lead equipment begins

By Steve Fiscor, Editor-in-Chief, E&MJ

Halfway between Phoenix and Tucson, in Florence, Taseko Mines operates the Florence Copper Project. It recovers copper, but it’s not a typical copper mining operation. Florence Copper uses in-situ copper recovery (ISCR) to extract copper from an ore body without disturbing nearly as much land.

The Florence Project is broken into two phases. Taseko is currently approaching the end of Phase 1, which included a production test facility (PTF). A total of 24 wells were drilled for the PTF and a pipeline carried copper-rich solution from the wells to a solvent extraction/electrowinning (SX/EW) plant. “We successfully produced more than 1 million lb of copper cathode from the PTF,” said Brent Berg, general manager, Florence Copper. “We have a small well field as well as an SX/EW plant, which was idled in June 2020. Right now, we’re working on rinsing the well field back to Arizona water quality standards. We’re also doing a lot of work on detailed engineering and permitting for Phase 2.” Phase 2 is the launch of a commercial-scale ISCR well field and copper recovery operation.

ISCR mines are different compared to traditional mining operations. The process involves no mining, no material handling, no comminution and no waste or tailings storage. “We use 93% less fresh water than a traditional mine,” Berg said. “Energy consumption is 71% lower and carbon emissions are 83% lower.”

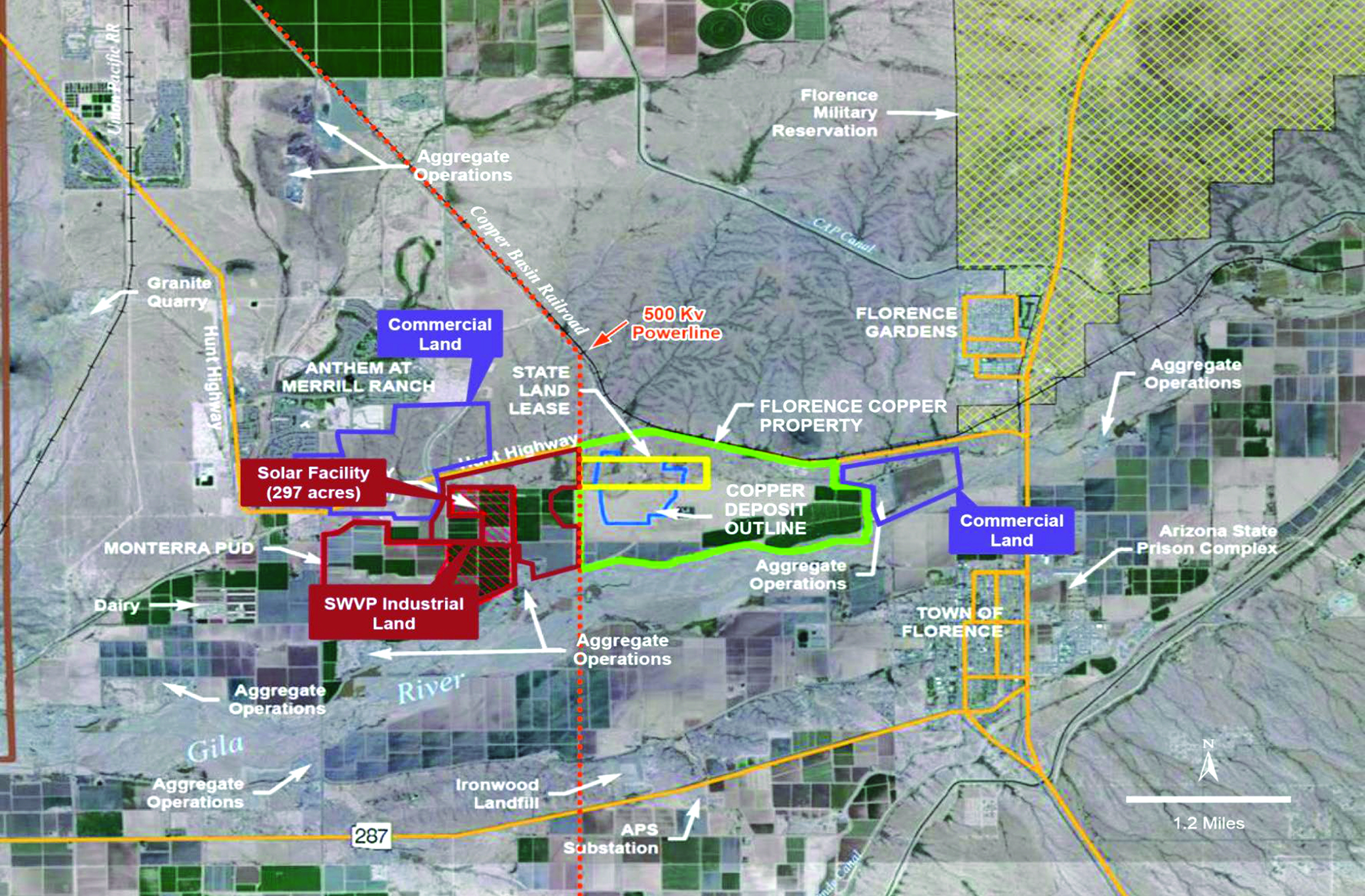

The blue outline is the ore deposit. The yellow outline are lands leased from the state of Arizona. The green outline is the Florence Copper Project.

Florence Copper currently employs 33 people, but that figure will grow to 140 to 150 once the mine reaches commercial operation. It will also employ 80 to 90 long-term contractors associated with drilling wells. “The well field will essentially be our mine development program,” Berg said. With probable reserves of 345 million tons grading 0.36% copper, the mine life for the operation is estimated at 16 years.

Once Florence Copper reaches commercial operation, it will generate a significant amount of income for the region, including $3.4 billion in economic activity for the state of Arizona; $2.1 billion in economic activity for Pinal County; and $468 million in taxes and royalties for the Arizona government.

Engineering Commercial Operations

The commercial facility is expected to have a production capacity of 85 million lb/y of copper. It will consist of a commercial-scale SX/EW plant and the associated infrastructure needed to pump raffinate from 80 injection and recovery wells. “The wells will be spaced in the same manner as the PTF,” Berg said. “All of the wells, whether they are injection, recovery or observation, will have a common multifunction design. The only change we’re making is with the casing for the screened interval. We will use a slotted, fiber-reinforced plastic pipe rather than PVC, something we discovered while operating the PTF.”

The commercial project will also have a small reservoir. “We neutralize the solution and evaporate it, so we will have a process water impoundment,” Berg said. “With ISCR, we have to maintain the inward hydraulic gradient, so there’s some over pumping from the well field.”

Stantec helps engineer the commercial facility.

Stantec has been working diligently with us on the engineering for the Phase 2 commercial facility, Berg said. “We’re advancing with commercial purchases,” Berg said. “We have purchased some long-lead equipment needed for the facility, like casings and other critical components, in anticipation of final permitting approvals. It’s good to finally be interacting with suppliers for this project.

One of the models Florence Copper uses (GoldSim) tracks all the hydrogeologic data, such as well flow rates, acid concentration, copper and acid recovery, active leaching zones, cut-off grades and well sequencing. “This system can model what each well will produce in real time,” Berg said. “Using actual data from the PTF, we have a pretty good idea of how the commercial facility will perform.”

Florence Copper is currently in the final stage of permit approvals. “We needed two key permits, the Aquifier Protection Permt and the Underground Injection Control (UIC) permit from the U.S. Environmental Protection Agency (EPA),” Berg said. “The Arizona Department of Environmental Quality approved the Aquifier Protection Permit in December 2020. As far as the final UIC, we have one for the PTF, but we need a much larger one for the commercial scale facility.”

On November 22, 2021, the EPA provided Taseko with a draft UIC for the Florence Copper Project. Taseko’s project technical team completed a review of the permit. The EPA will host a virtual 45-day public comment period. The EPA will respond and hopefully issue a final permit.

Detailed engineering and procurement activities are under way and, once Florence Copper has a final permit in hand, they will begin building the commercial plant and drilling the commercial well field with an 18-month construction window.