Documenting the mines of the American West, E&MJ Editor Rossiter W. Raymond informs and educates, while pushing for constant improvement

By Steve Fiscor, Editor-in-Chief

George F. Dawson’s tenure as the editor of the American Journal of Mining (AJM) was short-lived. After overseeing the startup of the AJM in 1866, he faded away after a year or so. Rossiter W. Raymond took over as editor. He was an American mining engineer, author and legal scholar. The newspaper benefitted by association, as Raymond strived to educate the mining industry and improve its reputation.

Raymond was educated at the Royal Mining Academy in Freiberg, Germany. He rose to the rank of captain under John C. Fremont during the Civil War. In October 1867, Raymond began a 23-year career as editor of the AJM, which would become The Engineering & Mining Journal (E&MJ) in July 1869. Using his position to expose swindlers and poorly managed mining companies, he became an influential voice for mining in America. Under his leadership, E&MJ emerged as the authority.

His work with E&MJ was only one face of a multifaceted career. In 1869, he was appointed U.S. commissioner of mining statistics. Working with others, he explored and documented the western U.S., filing eight annual reports between 1868-1875, which today serve as the historical foundation for information on the California gold district, Nevada’s Comstock Lode and various mining camps throughout the Rocky Mountains.

His work with E&MJ was only one face of a multifaceted career. In 1869, he was appointed U.S. commissioner of mining statistics. Working with others, he explored and documented the western U.S., filing eight annual reports between 1868-1875, which today serve as the historical foundation for information on the California gold district, Nevada’s Comstock Lode and various mining camps throughout the Rocky Mountains.

Raymond was instrumental in the founding of the American Institute of Mining Engineers (AIME) and served the organization throughout his career. Under his direction, E&MJ routinely published the minutes from the meetings and the papers that were presented, until AIME began to publish it themselves in annuals called Transactions. He edited that publication as well.

Shortly after Raymond took control of E&MJ (May 30, 1871), The Scientific Publishing Co. bought E&MJ from the founding publisher Western & Co. The editorial staff at E&MJ maintained its offices at 37 Park Row. They said his office in Lower Manhattan was the unofficial center for the mining engineering fraternity. On July 4, 1871, E&MJ transitioned from a weekly newspaper to a weekly magazine. Its physical dimensions were now smaller.

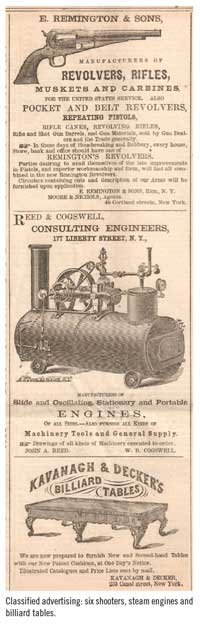

The publication maintained a strong dialogue with its readership, publishing letters from mining engineers around the world. In addition to metals markets and news, articles covered advances in mining, drilling in particular, and mineral processing. Raymond voiced opinions often with a sense of humor about many aspects of mining and society. The magazine carried a department called Popular Science, which discussesed everything from Darwin’s The Origin of Species to rebuilding Chicago.

In his late 50s, Raymond studied law and was admitted to the bar in 1898. According to the National Mining Hall of Fame, his writing on mining law was clearly phrased, and his expert testimony in suits over mining rights helped clarify this perplexing subject. These six paragraphs do not do this man justice for his achievements. At his memorial in 1919, Dr. Henry S. Drinker, president of Lehigh University, one of the two surviving founders of AIME at the time, remembered him as “one of the most remarkable cases of versatility that our country has ever seen—sailor, soldier, engineer, lawyer, orator, editor, novelist, story teller, poet, biblical critic, theologian, teacher, chess player—he was superior in each capacity. What he did, he always did well.”

DRILLING & BLASTING

During this period, miners were working with crude pumps and drills powered by steam engines and compressed air. Until this point, holes were drilled through rock by striking a steel with a double jack and rotating it a quarter turn in the hole. Gradually, powered drilling improved, first with percussive action. Unsatisfied with its performance, Rudolphe Leschot added rotary motion to the percussion drill. The American Diamond Drill Co. made further improvements, embedding diamonds in the steel bits and bore heads for core samples. The bits were attached to hollow steels and water is used to flush cuttings from the hole.

“No formation has been found hard enough to resist [diamond drilling]… “It is claimed, and from the testimony adduced, we cannot doubt it that these drills need few if any repairs, and the diamonds no sharpening.”—November 21, 1871.

During this period, E&MJ published correspondence with readers talking about the promise of diamond drilling. They compared notes on drill performance and drilling speeds in different geologic formations. E&MJ called attention to some of the advantages that may be obtained by the aid of these “ingenious” machines in practical mining operations. A copper miner from the Ducktown mine in Tennessee, after having lost the vein, explained how the diamond drill was used to find its continuation. He talked of drilling hundreds of feet in many different directions in a very hard formation until they located the vein again—something that would have been impossible only a few years earlier.

Blasting methods were improving as well. Until the late 1860s, the choices for primary blasting agents were either black powder or nitro glycerine; the former doesn’t work well in hard rock and the latter is difficult to transport and store. All of that changed when Alfred Nobel introduced dynamite, which is initially introduced to the E&MJ reader as Dynamid.

“Mr. Nobel, the chemist of Hamburg who introduced nitroglycerine, has brought forward a new compound, called Dynamid, or Giant Powder, which now commands much attention on both sides of the Atlantic. In Germany, England and California, experiments have been made with this substance, the results of which are as satisfactory as they are astonishing…”—AJM, April 4, 1868.

Describing what has been reported in a Polish trade journal, the AJM described the new blasting agent to its readers. “The prepared article is a brownish powder almost like slightly moistened sawdust, inodorous and somewhat greasy to the touch. When ignited, it burns quickly, as damp gunpowder does, but without any explosive phenomena. In the same manner, it burns when a handful or even a manufactured cartridge of it is thrown into the fire. To blows and violent agitation of every kind it is perfectly insensitive…

“An effective explosion is only obtained when one end of an ordinary fuse is introduced into a special prepared copper percussion cap, at least a half an inch long, and heavily loaded with fulminating mercury. The fuse is held fast in the cap by the simple expedient of pinching the latter together about a quarter of an inch below the mouth…

“The cap is inserted into the dynamid. Once the free end of the fuse is lit, the explosion of the fulminate causes a simultaneous explosion with an extremely violent report.” AJM discussed the effects of water and temperature on the substance, noting that it “tastes like nitroglycerine and has the same toxical [sic] qualities,” which miners today refer to as the ice-cream headache or brain freeze.

“It seems to stand between gunpowder and nitroglycerine in point of initial power, but far above in point of safety. Indeed, the percussion cap employed to explode it appears to be altogether the most dangerous part of the affair.”

“The compound and method of manufacture of this new agent are as yet a secret; and the inventor will probably endeavor to keep them so.” The AJM editors suspected that the fabrication process was too simple to patent.

THE FIRST AIME MEETING

“We present herewith a tolerably complete account of the proceedings at the first meeting of the new American Institute of Mining Engineers (AIME), held at Wilkesbarre, Pa., May 16, 17 and 18, 1871.”—E&MJ, May 30, 1871.

Wilkesbarre is an anthracite mining district located relatively close to New York City. R.P. Rothwell, a mining engineer working the anthracite district, was unanimously elected temporary chairman and Raymond was elected as the secretary. A committee was appointed to approve rules for the institute. While waiting for the committee report, the meeting listened to a paper from Raymond on the Geographical Distribution of Mining Districts.

A committee report followed with a total of 22 rules or bylaws. The first stated the objective of the AIME “…to enable its members, comprising mining engineers and other person interested in mining and metallurgy, to meet together at fixed periods for the purpose of reading papers upon and discussion subjects which have for their aim the economical production of the useful minerals and metals, and the safety and welfare of those employed in these industries and to circulate among its members, by mean of publications, the information thus obtained.”

Annual subscription was $10 ($200 today) and any member making a donation of $100 ($2,000 today) or more would have a lifetime membership. At the time, they had 70 members who hailed mostly from New York and the anthracite mining region of eastern Pennsylvania; 22 men attended the first meeting. They formed rules regarding honorary membership and governance.

On the second day, the group visited various points of interest around Wilkesbarre including the Lehigh Valley Co. They marveled at the arrangement of new coal breakers. In the evening, they held another session at the Wyoming Valley Hotel. After business concluded, papers were presented on Waste in Coal Mining and A New System for Mine Ventilation. A vigorous discussion ensued and it is well documented in this edition of E&MJ.

THE MINING LAW OF 1872

THE MINING LAW OF 1872

The U.S. was struggling to maintain order among the mines on the western frontier. From the beginning, E&MJ discussed the merits and the problems of mining laws for federal lands. The circumstances, however, were as complex as the mineralized geology. And, similar to legislation today, the unintended consequences created problems for the mines, which were on the verge of lawlessness and accustomed to protecting their claims by any available means.

“It was anticipated, when Congress passed the law regarding mining titles, that speedy end would be put to the confusion which had hitherto reigned in the mining states and territories, and that every proprietor, by possessory or miner’s right, would hasten to obtain a patent, under the broad seal of the United States. This expectation has not been realized. On the contrary, the number of applications for patents has been very limited; and at this rate, the reconstruction of the system of tenure of mineral lands, will not be effected in a century. The new expedient is only a new element of chaos added to the old.

“One reason why the miner does not apply for a patent under this law is very simple. It is not made compulsory; and hence, he considers the ordinary miner’s title good enough and avoids the unnecessary expense and formality of the governmental programme [sic].

“Again, many mining claims, owned by prospectors, or miners in a small way, are surrounded by a swarm of nuisances in the shape of rival claimants, blackmailers, etc. who wait to see whether the mines will be valuable before pressing their various threats. In numerous cases, these parasitic adventurers drop off in the course of time because there never comes a particular moment when they are willing and ready to fight or able to force a compromise. We regret to say also that in many cases, the proprietor only cares to ‘worry along,’ till he can make a sale, and leave to his successor all the legal, as well as mechanical, metallurgical and financial difficulties of the enterprise.

“Now the moment an application is made for a government patent, every man who has an adverse claim, however shadowy, may enter his protest, and the most valid counter claim will be null and void, if it is not pressed when due notice is given by register of the application made. It is evident, then, that to file such an application, is to pull the string to a very shower-bath of vexatious litigations, precipitating difficulties, which might otherwise never become troublesome, or at least might be dealt with singly, and gradually overcome or evaded.

“Capitalists about to purchase mining property, always should, and doubtless generally do, demand the absolute security of the United States patent; but in the view of the circumstances to which we have alluded, we can hardly be surprised that ordinary proprietor, in peaceful, though perhaps dubious possession, do not feel inclined to turn an armed truce into an uncertain strife. This is one of the points to which attention must be given. It is no easy matter to devise a general mining law, which shall be at once efficient and acceptable.”—AJM, July 4, 1868.

On January 15, 1872, Aaron A. Sargent (R-CA) introduced HR 1016, now known as the General Mining Act of 1872. The U.S. House Committee on Mines and Mining debated it for less than one week. This house committee was established in 1865 and had jurisdiction over the Geological Survey, the Bureau of Mines, the establishment of mining schools and many other areas related to mining. It was abolished in 1947 and its duties were transferred to the U.S. House Committee on Public Lands.

The U.S. House of Representatives passed it on January 23, 1872. The bill passed the U.S. Senate on April 16, 1872. It was signed into law by President Ulysses S. Grant on May 10, 1872.

“We publish this week the full text of the new Mining Law. From our point of view, it must be considered an exceedingly satisfactory selection from the innumerable suggestions offered, and opinions expressed by men in all parts of the country, for it embodies much that we have advocated. But we think that it will be read with acceptance by most of the large body of practical miners in the United States, whatever criticisms they may make upon particular provisions, must agree is commending the tone with which mining legislation has assumed, and the character and protection offered to their property.

“This law aims to offer means for a fair adjustment of thousands of claims upon all kinds of mining property and lying between men of every class and nationality. Probably the most eager curiosity in reading it for the first time will be directed, not to the sections which prescribes how mines may hereafter be taken up, but to the inquiry, how the law affects present interests, and the disputed points of the past.”—E&MJ, May 28, 1872.

The editors then pointed out possible problems with the law. For example, the first section said, “None but citizens, and those persons who declare their intention to become such, can have ownership…” The U.S. had been inundated with immigrants seeking a better life and many of them migrated West working the mines and eventually staking claims of their own. Even back then, when the U.S. Constitution was less than 100 years old, scholarly types were debating the definition of citizenship, much as they are today.

E&MJ fully supported the section giving absolute title to a certain surface and thought including all within vertical lines drawn from the boundary of the surface claim was an absolute necessity. The law stipulated the size of a claim that a miner may choose be a space not less than 50 feet (ft) nor more than 600 ft and not more than 1,500 ft long. Within the boundary the miner selects, all ore between the United States and the center of the Earth is his subject to one condition, which is, when other veins cross his, their owners shall have the right of way through his ground.

The editors disagreed with parts of other sections, particularly the provisions of Section 5 to allow owners who have abandoned a mine to resume work without relocation. “Something is needed to prevent a man whose whole time is spent in Utah from holding claims in California, Oregon, Montana and the other territories.” If the recorders couldn’t make annual inspections, then they thought the claim holders should have to swear to having performed the work required.

They also had problems with a lack of provisions for timber and the incomplete settlement of water power, and those aspects and others were amended later. Nevertheless, Raymond thought the General Mining Law of 1872 was a great advance on anything they had previously and it has largely stood the test of time.

The Eight-Hour Question

In nearly all well-regulated mines there are three “shifts” of eight hours each in the twenty-four hours, so that the miner works but eight hours, and sleeps and writes, reads, eats, or does anything else he likes during the other sixteen. We doubt whether there is any harder work in any calling than in mining, and hence the eight-hour system is almost a necessity among miners. With other laborers it is different. They breathe the fresh air of heaven, they have comparative freedom of action, and are neither cooped nor cramped up in the damp and sometimes reeking subterranean depths, where-in miners gather ores whose metallic products form the mainspring of the commercial world. The Labor convention, recently held in Baltimore, was on this account, a failure. Resolutions were passed, and a committee, waiting on the President of the United States, was received with kind words—that was all. Efforts of such conventions never do amount to much, and so long as people know that nine and ten hours labor at most kinds of manual work are not too much for the physical frame to endure, so long will such efforts be abortive. It is simply a question of profit, governed by humanity. The employer wants and must have as much work out of his employee as can reasonable be had without impairing his health, and the subject of wages and work-hours can never enter definitely into politics, no matter what efforts are made to that end.

—AJM, September 1, 1866