Tailings storage facilities can be difficult to monitor for ground movement, using typical conventional methods. Advances in satellite-based radar technology, however, can make this important task easier—and safer.

By Roger Morin

InSAR is a proven technique that has been applied widely to mine environments for many years with increasing acceptance. In 2005, for example, a major engineering company used InSAR data to evaluate the stability of a waste dump at this inactive mine in northern California. (Photo: ESA)

Tailings storage facilities (TSF) are very complex structures that are intended to work in harmony with the environment throughout the life of mine (LOM) and beyond. In recent years, that delicate balance with the environment has been shattered along with public confidence in the mining sector. Failures of tailings storage facilities are becoming all too common: from the Padcal mine, Philippines to Mount Polley, Canada, to the catastrophic failure at Samarco in Brazil, which unfortunately caused significant loss of life and widespread environmental damage.

These failures have been widely reported, studied and analyzed. According to statistics generated during the Mount Polley breach review, the Independent Expert Engineering Investigation and Review Panel stated: “If the inventory of active tailings dams in the province remains unchanged, and performance in the future reflects that in the past, then on average, there will be two failures every 10 years and six every 30.” Given the size and magnitude of the Samarco failure, and not knowing which dams are in line to fail next, the potential for another large scale incident is staggering.

The report commissioned as a result of the Mount Polley breach also stated: “The path to zero needs an added dimension, and that dimension is technology.” MDA is uniquely placed to address some of these technology challenges.

Five years of observations with multiple independent image modes. Blue and green lines from independent measurements are clearly measuring the same motion.

As a recognized leader in radar technology, MDA has developed Interferometric Synthetic Aperture Radar (InSAR) algorithms capable of detecting subtle ground movement with survey grade accuracy, measured to within millimeters. InSAR has been identified as a game-changer and a must have in any geotechnical or geomechanical tool box.

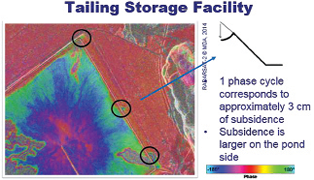

InSAR is a proven technique for monitoring ground surface movement in many diverse environments. The technique has been applied widely to mine environments for many years with increasing acceptance due to the reliability of contemporary InSAR processing. The InSAR principle lies in the measurement of the distance between the satellite and a point on the Earth’s surface, using the radar phase information. By subtracting the distance measured on two different days, information is obtained about the movement of the point.

Since the introduction of InSAR monitoring in the late 1980s, MDA has developed three generations of InSAR algorithms to increase the use and accuracy of ground deformation measurements from satellite radar. Monitoring with third-generation InSAR allows risks associated with ground motion to be captured and understood in various mine regimes. We have demonstrated the use of satellite observations acquired from two directions to show east/west and vertical components of motion, which provides accurate monitoring of ground movement at high-resolution.

Recent case studies applying the current third generation of InSAR methods have demonstrated that the accuracy of InSAR surveys can be better than ±2 mm. Early assessments of the same mining environment with earlier InSAR methodology have showed discontinuous measurements of ground movement. The third-generation techniques provide increases in accuracy, resolution and point density as compared to earlier generations of InSAR processing such as point scatterer techniques. Early comments from industry professionals have seen this technology as not only influential in its ability to take monitoring of tailings storage facilities to a new level, but as a technology that can be implemented right now to complement any ongoing monitoring program.

TSF are complex, large structures. It’s not uncommon to find embankments with a crest height of 25 m or more and an overall embankment length exceeding 5 km. Monitoring a structure of this size can be a daunting task using conventional methods. The technology developed by MDA has made these structures much more manageable to monitor throughout the LOM and into perpetuity.

As we saw with the Mount Polley review, in situ instrumentation has its limitations. Piezometers installed at the time of construction, along with other instrumentation, can fail or become damaged and no longer provide useful information. Replacement of failed or non-recording instruments can be a futile endeavor due to the frequency of failures, complex embankment design and the challenging environment. InSAR has been viewed as the “safety net” or the “guard dog” of impending ground movement, taking over where in situ instrumentation lags. InSAR requires no physical installation of ground monuments or instrumentation of any kind in order to provide accurate and reliable ground deformation monitoring over a much wider area than that covered by instruments or surveys.

InSAR requires no instrumentation of any kind and rarely requires the installation of ground monuments in order to provide accurate and reliable ground deformation monitoring over a much wider area than that covered by instruments or surveys.

Radar technology requires a strong and coherent signal returned to the sensor (satellite) from natural or man-made targets on the ground surface. Even in the harshest environments, MDA’s advanced processing technology and methodology has proven the value that this technology brings to mining operators around the world.

Having high-resolution quality data, not only from a reliable source, but also from a structured and consistent monitoring program, is essential to make remote sensing a valuable source of information for early notification of abnormal dam behavior. Historical or archived radar satellite data is equally valuable to provide an understanding and assess the behavior characteristics of any TSF. Radar satellite data, such as that provided by RADARSAT-2, allows for the study of both historical ground deformation and forward monitoring. Historical ground deformation is critical in establishing an accurate baseline for more focused and forward monitoring or surveillance of early signs of ground motion. Forward monitoring plays a vital role in better understanding the natural behavior of mining dams. For example, effective monitoring data can be collected during the construction phase, monitoring of known high-risk zones, monitoring slope stability and detection of new movement potentially caused by natural ground settlement or by presence of tailings slurry entering into the containment zone.

The use of InSAR is gaining in popularity and acceptance, not only by mine operators as a cost-effective means of monitoring large and sometimes challenging areas, but also by geotechnical engineering consultants whom have come to understand and appreciate the high level of reliable data and measurements provided. When combined with more traditional methods of monitoring, this added dimension is priceless. InSAR technology is relevant from the early onset of mine development through to closure to provide well-established baseline data, which coupled with traditional monitoring sensors provide information to manage mineral extraction projects and associated risks.

As mining regulations evolve to keep up with technological advancements in design, engineering and monitoring, it is conceivable that InSAR gets recognized in mining regulations as an acceptable and recommended monitoring technology. In the future, mine operators may be required to provide reliable and uninterrupted (long term) monitoring data from InSAR as part of their relinquishment permit for returning the property back to the control of the local authorities. Tailings present a long cost and risk to the mining industry and community, and should be monitored regularly even after relinquishment.

Connecting InSAR displacements with available data layers such as GIS analyses, field data and geomechanical modeling optimizes the understanding of potential geohazards. InSAR is a powerful tool for monitoring large areas, such as total mine tenement and adjacent areas and terrain. InSAR analysis can detect and accurately measure surface motion indicating potential onset of geotechnical hazards. The high spatial density of InSAR measurements is a valuable input to constrain geomechanical models, which allow us to better understand the measured surface displacement. InSAR has been recognized as a cost-effective tool for monitoring all mining infrastructure throughout LOM and well into perpetuity.

Roger Morin is global business development manager–mining for MDA Geospatial Services, Inc. He has more than 25 years of mining experience with a primary focus on advanced extraction methods, automation and technology deployment.

Potash Miners Pay Attention to Subsidence With InSAR

InSAR’s ability to accurately monitor ground movement isn’t restricted to tailings applications. In a case history published by MDA, the British Columbia-based company describes the role its technology plays in another Canadian province’s mining industry.

Potash mining is one of Saskatchewan’s key industries and revenue generators. As potash mining has grown, so too have the province’s cities and rural communities. Although the mines are located at a depth of 1,000 m to 1,600 m, most lie below critical aquifers and many now extend under human habitation and infrastructure. Detecting even minute changes in surface elevation is a vital tool in preventing damage both above and below ground, and serve as indicators requiring remediation efforts before problems escalate.

InSAR uses two or more radar satellite images acquired over time using identical satellite position and altitude to measure movement of a ground feature with millimeter-level accuracy. RADARSAT-2, a powerful synthetic aperture radar satellite built and operated by MDA, is capable of imaging the same location on Earth with identical imaging geometry, regardless of cloud cover or lighting conditions. This approach covers broad areas at relatively low cost per kilometer, but provides detailed information on localized areas of detected movement. Over time, image acquisitions are stored in a digital “stack” that provides a time-lapse view of subtle changes in surface elevation. This enables decision makers to see where problems are occurring, and to track the effectiveness of remediation work.

InSAR, according to MDA, benefits the potash mining sector with its ability to assess, on a regular basis, the impact of surface movement on surface and subsurface operations, providing a cost-effective, unobtrusive method of detecting and mapping ground movement over a broad area. Early detection of changes allows operators to address remediation efforts before problems escalate. For potash mine operators, InSAR generates a stream of information provided in a concise report to supplement existing monitoring methods such as GPS, tiltmeters and micro-seismic monitoring.