Specialized Buckets for Mining

The Danish company, Viby Attachment, specializes in producing buckets for hydraulic excavators, wheel loaders and other materials-handling machines. It has delivered more than 40,000 units during its 50-year history, supplying buckets to OEMs and end-users.

Viby manufactures its excavator buckets in Hardox and Weldox steels for all machine types and uses. Various teeth brands can be fitted according to customer’s specifications, it pointed out.

For wheel loaders, its high-tip bucket is the only one available with completely protected cylinders, it added, while standard loader buckets can be provided with spill guards, wear plates and other options, including quick-hitch systems.

Real-time Analysis for Better Grade Control

IMA Engineering supplies geochemical analyzers to customers in the mining, construction, cement and industrial-minerals industries. Its products include analysis systems for online cross-belt applications, slurries, truck and train loading, and exploration and mine-grade control. The acronym IMA stands for Innovative Mineral Analyzers, the company explained.

IMA’s Fast Conveyor Analyzer being used to identify ore types on the move.

IMA’s Fast Conveyor Analyzer being used to identify ore types on the move.

IMA designs and manufactures fully automatic instant drill-cutting sampler-analyzers for Atlas Copco, which distributes them under the brand name OREAlyzer. These units are used on reverse-circulation sampling and blasthole drill rigs to produce accurate depth- and location-specific ore-grade data that can then be used to produce 2-D or 3-D loading maps for selective loading for grade control. Their accuracy has been verified by excellent correlation between the OREAlyzer results and those from adjacent diamond and reverse-circulation sampling, IMA stated, with OREAlyzer units having been delivered and tested in various copper, nickel, iron and limestone mines in Scandinavia, Australia and the U.S.

IMA also manufactures various types of on-belt analyzers using XRF, LIF and LIBS analysis technology, which can be controlled through a process management station. Fast analysis in less than a few seconds is essential for identifying waste rock and different grades of crusher-run ore for sorting purposes, the company said. Its FCA (Fast Conveyor Analyzer) system allows up to eight analyzers to be connected to one station, while several stations can be linked for data-view or system-control distribution.

XRF analyzers monitor crushed ore on a conveyor belt, or analyze oxide and elemental compositions in finely ground dry powders or wet slurries at concentrators and other process plants. Typically they are used in cement production and in metallic mineral applications to monitor the main oxides. Laser-based (LIF, LIBS) analyzer systems are designed for the identification of mineral types or quality classes to provide real-time quality-control information, with their main use being dilution control in run-of-mine ore.

IMA said that another interesting application is the use of its bucket analyzers for sorting ore and waste rock while loading. It has a full-scale research unit that interested customers can rent and use for on-site trials. The system is especially useful for underground stopping or block-caving, IMA said, while it can also be used in surface mines for mill-feed homogenization.

Minerals-processing Technology Developments

The Finnish supplier of minerals-processing and metallurgical technologies, Outotec, reported it has added high-pressure grinding rolls (HPGR) to its comminution product line, which also includes autogenous-grinding mills, SAG mills, ball mills, rod mills, scrubbers and HIGmills (high-intensity grinding). HPGR technology can be applied to various minerals-processing applications where project feasibility demands lower energy consumption, Outotec explained.

The company has also developed its own range of HPGR tires. It pointed out that since they operate in a highly aggressive environment, HPGR tires are plagued by problems such as studs cracking, breaking or shattering. Studs can also be undermined or washed out along the tire base, separating them from the tire. In addition, Outotec said, the edges on HPGR tires can often experience uneven or high wear, leading to compromised grinding performance and premature breakdowns.

Outotec said its HPGR tires are built for maximum performance and durability, incorporating a unique design with extremely high-wear material. The stud and edge design deliver optimized throughput over the tire life cycle and extend the intervals between services, it added.

Turning to filtration, Outotec has responded to the mining industry’s increasing demand by upscaling its Larox FFP 2512 pressure filter series to the new FFP 3512 for even higher-capacity production requirements. It claims that the innovative design of the membrane filter plate is the key to achieving larger capacities, and even more efficient process results, with the FFP being designed for the dry stacking of tailings, providing energy and water savings through water recycling.

Both the 2512 and 3512 series share the same footprint to simplify future expansion requirements. The 3512 filters offer filtration areas of up to 991 m2 with fast pack opening, and are equipped with the latest technology filter plates that have been designed for mining conditions, Outotec stated.

Outotec’s recent supply contracts have included the complete process system for First Quantum Minerals’ Kevitsa copper-nickel mine in northern Finland, which came on stream in August 2012. Outotec delivered two autogenous-grinding mills, a pebble mill, 73 TankCells ranging from 20 to 300 m3, three high-rate thickeners, two Larox PF 25 m2 filters (later expanded to 32 m2), an Outotec PSI 500 particle-size analyzer for the grinding circuit, and a Courier 6i elemental analyzer for the flotation circuit for froth control. Other equipment included 36 FrothSense imagers, an Outotec ACT (Advanced Control Tool) for flotation optimization, and its Integrity concentrate reporting tool.

Outotec also trained the plant’s operators using its Virtual Experience simulation system, has service agreements covering the various analyzers, is providing First Quantum with mill-lining services, and has a two-year operations and maintenance agreement for the filters.

Real-time Information for Exploration Results

A sister company to the analyzer supplier, IMA, Mine On-Line Service (MOLS) provides the exploration and mining industry with services such as core-logging and online geochemical analyses, especially on drill cores and till samples. MOLS also does drill-cutting and grade-control application studies, and consulting for optimal solutions at various points in a mine’s value chain. The company stated that its focus is not only on eliminating capex and reducing opex, but on generating value from the accurate differentiation of ore and waste, the ore grade and its location.

An underground job for MOLS’ Scanmobile mobile geochemical analysis lab.

An underground job for MOLS’ Scanmobile mobile geochemical analysis lab.

MOLS said that its rapid analysis services allow several hundreds of meters of drill-core scanning a day. Analysis reports are available virtually instantly for the client to view remotely through their secure Remolog online reporting and logging tool. Along with patented sampling instruments, 3-D blast-field modeling technology, heap-leaching optimization and real-time reporting software, IMA analyzers are a great asset to MOLS.

MOLS has been digitizing drill cores in national core stores and mines across the Nordic countries for years with its Scanmobile mobile geochemical analysis lab. This documents drill-core data using non-destructive XRF elemental analysis, as well as using built-in digital imaging technology to evaluate characteristics such as the rock quality (RQD), and to identify minerals. The results are fed to the online Remolog browser, and can be viewed remotely from anywhere with an Internet connection. The Scanmobile system is currently being developed to include integrated magnetic susceptibility analysis and other analytic techniques.

Recent projects have included digitizing a large volume of drill core at a nuclear waste storage site. More than 4,000 core boxes with more than 18,000 m of core were photographed in a few weeks, with the images being analyzed for RQD and any weak minerals content. MOLS has also undertaken grade-control studies for mines, most recently for a nickel mine. Using a trailer version of IMA’s OREAlyzer, the production bench was closely analyzed and compared to the mine’s own data from the area. The results showed significantly higher ore losses and dilution than had been predicted.

As the representative for Blast Movement Technologies Ltd. in Scandinavia, MOLS can combine elemental analysis information from IMA analyzers and blast movement data to create accurate pre- and post-blast 3-D block models, displaying the ore-content distribution in production benches with GPS coordinates.

Pinch Valve Technology from Flowrox

With its headquarters in Lappeenranta, Finland, and subsidiaries in the U.S., Australia and South Africa, Flowrox specializes in supplying solutions for abrasive, corrosive and other demanding shut-off, control, pumping and dosing applications in a wide range of process industries. The company has accrued more than 30 years of experience in the elastomer technology used in its heavy-duty valves and pumps.

Flowrox has designed its new PVG range of pinch valves for reliable performance in harsh conditions.

Flowrox has designed its new PVG range of pinch valves for reliable performance in harsh conditions.

The company recently launched its new PVG pinch valve for processes involving pressure resistance, heat, abrasion, corrosion and aggressive slurries. The PVG is a robust pinch valve with strong metal body, simple bullet closing mechanism and opening tags in the inside sleeve as standard, Flowrox told E&MJ, noting that the design is based on direct feedback from the field, and responds to customer demand from various industries.

The PVG has evolved from the earlier elastomeric PVEG valve, designed for end-users needing a lightweight, but durable valve. While the concept was widely liked, the valve’s plastic body limited the applications for which it could be used, which led Flowrox to build the new, stronger version based on the earlier successful design.

The PVG valve offers process benefits that are based on the valve structure, the company said. In the open position, the valve is at full bore with no flow restrictions, so it is an integral part of the pipeline. Anything flowing through the pipe can also pass through the valve. Being a full-bore design, PVG valves require the least pumping energy and minimize the system head pressure. Installation is trouble-free, and the valve includes pre-installed rubber sleeves that withstand tough process conditions. This ensures long lifetime and minimal maintenance costs, Flowrox added, with potential applications including discharge lines, thickeners and pump isolation.

Flowrox also recently reported on an application involving another one of its products, the PVE pinch valve. A Danish utility was experiencing relative short service intervals (six-to-nine months) on a valve in the control system for lime slurries used in power-station flue-gas desulphurization. Its replacement with a PVE unit led to a number of benefits, according to Flowrox, which later supplied the utility with a second valve for use on a similar application.

The valves have been reliable in operation, with significantly better wear resistance than the units they replaced. In addition, Flowrox said, the service interval for the valves was stretched to more than 24 months without causing any disturbance to the lime slurry control.

Shotcrete System for Svalbard

The Danish company fibo intercon, which manufactures and delivers mobile, semi-mobile and stationary concrete-batching plants, told E&MJ that it has supplied a batching plant to the Norwegian coal producer, Store Norske, for the production of sprayed concrete (shotcrete). The M2200 plant has a production capacity of 25–45 m3/h, is mounted on a three-axle trailer and weighs 11 mt.

Fibo intercon supplied this mobile shotcrete mixer to Norway’s coal producer, Store Norske.

Fibo intercon supplied this mobile shotcrete mixer to Norway’s coal producer, Store Norske.

The unit consists of four aggregate hoppers, an agitator pan mixer, dosing equipment and a control unit for the batching computer. Fibo intercon also supplied other equipment for the plant, including a 14-m long belt conveyor for transporting the mixed concrete, a big bag silo for cement and a preweight silo for cement to ensure high-quality concrete.

Store Norske is using the batching plant at its Svea Nord mine. The M2200 operates from inside a large tent, with aggregates being fed using a wheel loader, and the finished concrete being taken underground using a truck mixer for delivery to the shotcreting rig.

When the Lunkefjell mine is opened, the plant will be moved underground through Svea Nord to its new location—and as the roof height in Svea Nord is only 2.5 m, fibo intercon built the M2200 2.46-m high. The company pointed out that by using a mobile unit like this, plant positioning can be optimized, with cost and time savings.

Fibo intercon noted that this is not the first time it has delivered equipment for mining and tunneling projects, with one of its most widely used plants being a horizontal 30-m³ capacity cement silo that is used in low-headroom situations. CEO Claus Holm, said, “We expect that mining will become an even more important market for us in the future, since many of our plants are tailored for sites with limited space or are easy to customize for mining and tunneling projects.”

SSAB Extends Hardox Network

Wear-resistant Hardox plate from the Swedish steelmaker, SSAB, is widely used in mining-sector applications. The company recently opened a Hardox Wearparts facility at Quilicura in Chile, where Hardox plates coming from the U.S. and Sweden are cut before delivery to mining and manufacturing customers in the country.

SSAB has also been working on a joint project with Scania to develop a lightweight, but heavy-duty tipper truck for use in applications such as coal mining. Introduced at last year’s bauma China show, the vehicle’s Hardox 450 body uses SSAB’s Arc Design, which gives a lightweight convex shape without floor stiffeners. Destined in this instance for use in Mongolia, where temperatures can dip to -50°C in winter, the body floor can also be heated using the truck’s exhaust to reduce the chance of the load freezing and sticking.

Meanwhile, SSAB has given notice that it intends to increase its use of legal action to protect its Hardox trademark against infringements—especially, but not exclusively in China.

“We would like all of our customers to be aware of the fake Hardox wear plate available on the market,” the company said. “The technical proprieties and wear performance of Hardox copies cannot compete with the genuine Hardox.”

Sleipner Shifts Bigger Excavators

The Finnish manufacturer of specialist equipment-moving systems, Sleipner, has pushed the limits of the machine sizes it can handle further with the introduction of its E550 model. Using this, open-pit and quarry operators can now move excavators weighing up to 565 mt around their sites quickly and cost-effectively, the company stated.

Having tested its new E550 excavator-mover successfully, Sleipner sold the first unit to a mine in Africa.

Having tested its new E550 excavator-mover successfully, Sleipner sold the first unit to a mine in Africa.

The new unit uses essentially the same concept as earlier versions, with large wheels, and ramps with axles, but with a new frame structure. Once one end of an excavator’s tracks have been driven onto the ramps and lifted off the ground, the excavator turns around, places its boom on the bed of a dump truck and lifts the other end of its tracks. With the whole excavator now clear of the ground, the truck can move it to wherever it is needed in a fraction of the time needed for walking it the same distance on its tracks.

Trials on the E550, designed for excavators between 450 and 565 mt, took place in Sweden earlier this year, using a Komatsu PC5500 excavator and a Caterpillar 793 hauler. Sleipner reported that the evaluation was completely successful, with the first E550 unit then being delivered to an operation in Africa. According to the company, its key customers are requesting even larger Sleipner equipment for their operations, and it believes that this model will have the biggest impact yet on mining operations—cutting transport times by up to 80% and increasing excavators’ efficiency and productivity.

Having the ability to move larger pieces of equipment brings its own challenges, of course, and Sleipner has now developed a towing application for demanding conditions. Consisting of a kinetic rope that is easy to use, safe and light, it allows two trucks to be used in tandem to tow an excavator on a Sleipner unit on steep (10%-15%) uphill grades, or when extra towing capacity is needed.

Dampening to a Whole New Level

With its company slogan, “Lights for Heavy Duty,” Nordic Lights produces LED, HID (Xenon) and halogen work lights for the heavy-duty on- and off-road industries in harsh working environments. As the company noted, powerful machines require powerful lights, with its principal product criterion being durability.

Nordic Lights’ QUAKE dampening system protects work lights.

For many years, Nordic Lights has been developing and patenting different dampening solutions for the heavy-duty lights used on earthmoving and other equipment. Why dampen a work lamp? The right kind of dampening will greatly increase a lamp’s resistance to shock and vibration. Not only will the lamp take much longer to break, but the different components inside it will also last longer, needing far less maintenance and fewer replacements. The strain on the application caused by mounting the work lamp will also be reduced, making the vehicle less vulnerable.

The company has now introduced its patented QUAKE dampening system, which takes protection against vibration and shock to a whole new level, the company said. In a standard dampening system, powerful strains can develop on the dampeners, whereas in the QUAKE system, forces are distributed uniformly. As a result, Nordic Lights said, the QUAKE dampening system lasts much longer and can withstand much bigger shocks and wider ranges of vibration. And if the dampening system can withstand more punishment, so can the work light and also the application upon which it is mounted, the company pointed out.

In addition, because the QUAKE system withstands a wider range of vibration, it is now possible to mount more powerful work lamps on vehicles. As a result, the question of where the work light is mounted is less critical since the dampening system is kinder on the vehicle, as well as reducing maintenance and down-time, and saving space.

Noise Monitoring for Mines

The Danish company, Brüel & Kjaer, a world leader in noise and vibration measurement, told E&MJ that it has started to make inroads as a supplier of environment monitoring services to the global mining industry. Noise Sentinel is a subscription-based monitoring service that helps mines manage their noise, ground vibration, dust and air-quality impact.

Monitoring using Brüel & Kjaer’s Noise Sentinel can help mines stay within emission limits.

Monitoring using Brüel & Kjaer’s Noise Sentinel can help mines stay within emission limits.

According to the company, Noise Sentinel is unique—not just because it combines all these disciplines in one solution, but because it provides a full service offering including instrumentation, installation, service and data management. This makes it possible for mine staff to focus on their core job instead of managing technology, Brüel & Kjaer added.

As well as being used in large mining operations in Australia and Brazil, Noise Sentinel has been operating for more than a year at Goldcorp’s Porcupine mine in Timmins, Ontario. Monitoring takes place at 17 different locations around the mine in challenging environmental conditions. Noise, vibration, dust and air-quality levels are continuously measured up to twice per second, and are automatically transmitted to the Noise Sentinel server over the Internet where they are processed and compared to a variety of compliance criteria. If levels exceed these, the mine staff are alerted immediately. Alerts are shown on a real-time control app that runs 24/7 in the mine control room, and are transmitted via email or SMS. This enables operational staff to take immediate action to reduce any impact.

As Brüel & Kjaer pointed out, noise does not just come from the mine. The system has shown that there is a general “urban hum” that includes lawn mowers, motorcycles and other road traffic. During the summer, evening concerts raise noise levels above defined limits. Noise Sentinel helps by recording audio when limits are exceeded. Replay can help to determine if the cause was due to the mining operations or other sound sources in the community. It can also use directional noise monitoring, which is able to measure noise levels in a specific direction—for example, the mine—and exclude noise from others, such as the community.

Improving Work-flow Systems

As the need for automated, online information in mining has increased rapidly, the Tamtron group has answered this challenge by developing a robust, reliable on-board dump-truck scale and ID tracking system with various ways of transferring data wirelessly and on-line.

Tamtron’s DV dump-truck scale for heavy-duty use consists of two axle load cells that replace the rear pins of the dump body, a pressure transducer that measures the pressure in the piston cylinder, and an advanced display instrument, designed for on-board use. The use of both types of transducer ensures that the weighing result is correct in every position of the dump body. Weighing takes place simply by lifting the body, with inbuilt angle compensation ensuring that the weighing is accurate even on rough ground. DV scales can be installed on most trucks, including underground haul trucks, the company said.

Tamtron scales are equipped with a large on-board touchscreen display—re-launched earlier this year with a new user interface in full color. Both the display and keyboard are illuminated, enabling round-the-clock use. On-board weighing means that it is no longer necessary to drive to a weighbridge, which saves time.

The DV scale range covers all needs from basic weighing to advanced data transfer versions. The weight data are stored in the system’s memory, which can generate detailed records of the material type, amount loaded and location of the material. Tamtron pointed out that the DV scale helps to avoid overloading, so fleet utilization is more efficient and servicing is reduced.

Meanwhile, Tamtron’s ID tracking system means that identifying vehicles and personnel on a work site need not be difficult or take up human resources. Its automatic RFID systems—based around RFID tags and an RFID data-collection terminal—log identification data directly, with these data then readily available. The ID data can also be integrated into existing business processes like HR and ERP for further information management. There are various options for the data network, and all of Tamtron’s systems are tailored to meet customers’ needs.

Cutting Concentrate Drying Costs

The Kopar group, the Finnish manufacturer of process equipment for smelting operations, has designed a new steam dryer to dry concentrates before they enter the furnace. According to the company, the new dryer—which is patented in Europe—offers many features that enhance the drying process in comparison to existing dryers.

Since most smelting operations produce steam, using this is an economical solution compared to using outside energy sources. Another positive aspect is environmental. Since the new dryer works at lower temperatures, the process also produces lower emissions.

The company explained that the European patent is fundamentally about the arrangement of the heat-pipe system that consists of heat-transfer elements. The heat pipes are co-rotating, which means less mechanical wear on the steam tubes, so maintenance intervals are longer.

The structure includes several new features: no pressurized pipes in supporting contact; no massive construction inside the dryer; fewer steam-distributing pipes; a high heat area-to-drum volume ratio; and a low length-to-diameter ratio.

Kopar noted that the new dryer, which is available in several sizes, is aimed primarily at copper smelters but that other metal concentrates and ores can be processed as well.

Maintaining Roadways Underground

A pioneer in motor-grader technology, the Finnish company, Veekmas, is the Nordic countries’ only manufacturer of these specialized machines. Its product portfolio includes graders for traditional construction and show/ice removal, together with low-profile motor graders for use in hard-rock underground mines.

A Veekmas FG 7 C grader at First Quantum Minerals’ Pyhäsalmi mine in Finland.

Still a family-owned company that has been building graders since the early 1980s, Veekmas draws its product-development ideas from customer feedback as well as its own operating experience. Having established a dealer network on five continents, last year it launched its underground graders in both Australia and Mongolia. More machines are now scheduled for delivery to Mongolia, and it will deliver its first graders to Russia later this year. “We have a record number of motor graders in manufacturing at the moment, with the demand for underground graders stronger than it has been for many years,” Sanna Halttunen, the company’s export director, told E&MJ. As a result, Veekmas has been taking on new staff and has built a new assembly hall in preparation for the expected increased demand.

Veekmas currently offers three underground grader models. The 8.1-mt FG 5 C is powered by a 75-kW engine, is barely 2-m high and has a 4.9-m maximum outside turning radius with a front blade. The FG 7 C weighs 9.8-mt with a 90-kW engine, and is 2.46-m high with a 4.95-m maximum turning radius, while the company’s largest machine, the FG 15 C, weighs 16-mt, is 2.66-m high, has a maximum outside turning radius of 7-m without a front blade and is powered by a 150-kW engine.

Recent improvements to the FG 7 C have included a new electrically controlled system for the hydraulics, making the machine easier for the operator to use, new ROPS certification for the machine’s strength and sturdiness, even better visibility from the operator’s position, and the option of front-wheel braking to make the grader even safer in demanding underground conditions.

Veekmas stated that while a motor grader is the most suitable machine for proper road maintenance tasks, underground conditions are different from those on the surface. Hence, it is challenging to use a traditional grader underground where tunnels can be narrow, the walls are close to each other and there are sharp turns. By contrast, its machines are specifically designed for these conditions, being low and strong with an automatic, hydraulically operated blade suspension system that helps reduce shock impact loads on the frame.

Mining Pipework

Sweden’s Alvenius offers two systems of pipework and fittings for mining, hot-dip galvanized and thermoplastic (TP)-coated. Hot-dip galvanized systems are used for applications such as transporting water, compressed air, slurry and backfill, and for dewatering.

In business now for more than 60 years, Alvenius offers both the K10 and Victaulic systems, with K10 being a shouldered system for pressures up to 25 bar (360 psi) and Victaulic being a grooved system for pressures up to 80 bar (1,160 psi). Both are available in pipe diameters of 48 mm-508 mm (2-20 in.).

Coating steel pipe internally and externally with thermoplastic provides a solution for handling corrosive fluids at pressures of up to 70 bar (1,000 psi). TP pipes are available with diameters from 89 mm to 508 mm (3½-20 in.) and are typically used in applications such as heap leaching, dewatering, process water, fire fighting and for solutions with a high acid or chloride content.

Commissioning Drives at Oyu Tolgoi

Since the beginning of 2011, Sweden’s Hägglunds Drives has been a fully integrated part of Bosch Rexroth, although the name is used for the radial piston motors and hydraulic drive power units that drive systems such as conveyors, bucket-wheel reclaimers, ship unloaders, cement kilns and other heavy-duty applications.

Bosch Rexroth has a total of 10 drives and 21 electric motors in operation at the giant Oyu Tolgoi copper-gold mine in Mongolia. The company reported that two of its service technicians, recently scheduled to carry out warranty work on some Hägglunds equipment there, ended up commissioning all of the main conveyor drive systems on site.

The two technicians were originally intended to replace 21 electric motors to suit the harsh climate conditions at the mine. However, faced with an urgent requirement to get the operation opened on schedule, they were first tasked with commissioning the drive on the mine’s longest conveyor. This took four days, including testing. It quickly became apparent there were numerous wiring faults in the electrical systems that were connected to the Hägglunds’ equipment, so the technicians had to supervise the entire start-up process.

Following the successful start-up, and with the replacement work completed, the technicians were entrusted with commissioning the remaining nine drives. Because the specifications were unavailable for the site-installed couplings and pipe runs, Bosch Rexroth sent out its own flushing equipment and skilled service staff. The piping was cleaned out and eventually all 10 drives were commissioned. What had initially been slated as a straight-forward replacement job turned into a two-month marathon, although, as the company noted, it was able to sell the original electric motors for use in another part of the mine.

Rack-and-Pinion Elevators

Since its introduction of the Raise Climber in 1957, Alimak Hek has provided personnel and materials elevator systems to the mining industry. Its current indus-

trial rack-and-pinion elevator range includes the SE and SE-H models, which have load-carrying capacities of 2 mt and 3.3 mt, respectively.

The company’s elevators are built to a modular car design that provides up to 30 different sizes. Made of Alimak’s self-locking, aluminum profiles, the wall panels meet different elevator needs, and create adaptable floor and roof configurations, it said.

Typical mining-sector applications could include underground access, as well as running between different operating floors in crushing plants, concentrators, smelters and pellet plants. Underground, Alimak elevators are well-suited for providing a secondary, emergency access route. They can be easily installed, and are relatively cheap to do so because no hoist room is needed. In surface plants, meanwhile, they provide quick access from level to level in situations where operators have different pieces of equipment to monitor and control.

Borehole Survey Tools Aid Exploration

With its headquarters in Trondheim, Norway, and with branch offices in Hong Kong, South Africa and South America, since 1988, Devico has been specializing in directional core drilling for the mining and tunneling industries. The company recently introduced DeviShot, which, it claims, is the most innovative multishot survey tool on the market.

Devico said DeviShot is a magnetic survey tool that can be operated as either a single- or multi-shot instrument at constant or variable depth intervals. Whether surveying exploration boreholes, grout curtains or blast holes, DeviShot’s robust integrated running gear enables operation at exceptional depths, the company added.

DeviShot is equipped with an integrated IP68-rated Nomad PDA system powered by DeviSoft Mobile software. Using Brilliant Blue Technology (BBT) to communicate wirelessly with PDAs in the field, DeviShot provides quick results that can be further plotted and analyzed using DeviSoft, or quickly transferred to clients via a USB flash drive.

The DeviShot comes pre-assembled for use straight from the box, and features a BBT activation system to ensure minimal power consumption and longer battery life. DeviShot’s limited maintenance requirements and integrated survey data quality control features also help provide results in a quick, precise and cost-efficient manner.

Volvo Targets Further Efficiency Improvements

Volvo Construction Equipment (Volvo CE) reported that it is continuing to roll out its latest wheel loaders, articulated haulers, and hydraulic excavators for the mining and aggregates sectors worldwide. “Mines and quarries represent the largest portion of our business in many regions and for some product ranges,” said David Nus, global director for mining, quarry and aggregates. “No other supplier offers such a broad range of mobile solutions to mines. The recent launch of our new FMX trucks extends this leadership in the on/off-road environment. The FMX has been very well received by miners around the world.”

Volvo CE’s A40F articulated dump truck can be equipped with a full suspension system for greater operator comfort.

Volvo CE’s A40F articulated dump truck can be equipped with a full suspension system for greater operator comfort.

The company pointed out that its latest G-Series wheel loaders, F-Series articulated haulers and D-Series excavators feature Volvo powertrains suited for the emissions regulations of each market. Volvo was one of the first suppliers to bring Tier 4i/Stage IIIB-certified machines to the market in early 2011, with all Volvo CE ranges on schedule to include Tier 4f/Stage IV engines starting in 2014.

The industry’s first wheel loader in the 35-mt weight class, the L250G, was specifically developed for customers in mining and aggregates, offering increased capacity over traditional 30- to 32-mt class machines when digging, loading or rehandling.

Volvo CE’s latest F-Series articulated haulers have been updated to offer better visibility through the front windscreen, side windows and rear door, a patented, simplified load/dump brake interface and an integrated retarder/brake function now combined into one pedal for simplified use. The A35F and A40F ADTs can also be equipped with the company’s patented full suspension (FS) option, which increases operator comfort and will be important when whole-body vibration regulations coming into force in some markets.

Meanwhile, Volvo’s D-Series crawler excavators—such as the larger EC340DL, EC380DL and EC480DL models—now feature improvements such as faster digging and travel speeds, intelligent hydraulics, and enhancements to the undercarriage to extend reliability. The company’s unique boom float function also raises productivity and speed during truck loading, while increasing operator comfort and fuel efficiency. “This is free production for a mine, and more comfortable for the operator,” said Nus.

Volvo CE is exploring a range of new fuel-efficiency technologies for future use in its equipment, while looking at ways of improving existing technologies. “We believe there is still a lot of potential for fuel savings and increased performance from further developing traditional mechanical drivetrains,” Nus added. “Acquisition costs of new technology must be outweighed by operating cost savings that are reliable. The proven reliability of existing drivetrains, backed by a mature support network, is a practical advantage for our customers today in mines and quarries.”

One practical innovation, he said, is Volvo’s Optishift solution for wheel loaders, which can improve fuel efficiency in most applications just by integrating systems in a more intelligent way and simplifying operator control. “Optishift benefits any truck-loading or load and carry application—or nearly all loader operations. Gains in fuel efficiency have been measured at more than 15%,” he said.

Flygt Submersible Pumps for Mining

Part of the Xylem group, Flygt has been producing dewatering pumps since 1930 from its plant in southern Sweden. Its first submersible came in 1947, and since then it has been one of the market leaders in submersible pump technology with a raft of innovations to its credit. Aside from its Emmaboda facility, the company now has production units in the U.S., India, China and Argentina.

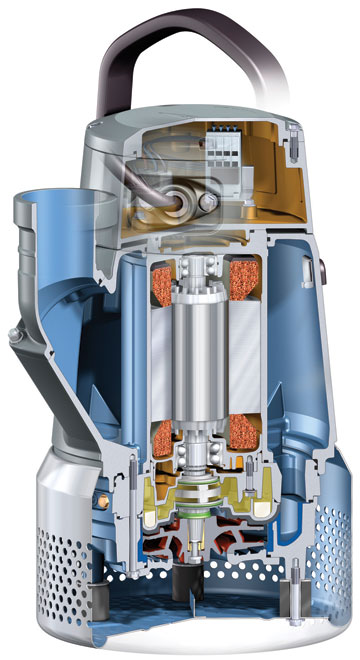

Cut-away view of Flygt’s BIBO 2800 pump.

Cut-away view of Flygt’s BIBO 2800 pump.

Xylem’s mining-sector product range encompasses both Flygt and Godwin pumps.

Flygt submersible pumps cater to a wide range of applications and needs, the company said. Its cast-iron 2000-series pumps; the 2600-series for tough applications in mining and construction, with a sludge version also available; the stainless-steel 2700-series for corrosive and abrasive liquids; the heavy-duty 5000-series for pumping slurry; and the most recent addition to its range, the Flygt BIBO 2800.

The BIBO 2800 pumps handle flows of up to 100 l/s (1,500 U.S. gpm), heads up to 90 m (300 ft), and solids of up to 80 mm (3.2 in.) in diameter. They are available with power ratings from 3.2 to 18 kW (50 Hz) or 5.9 to 27 hp (60 Hz). Flygt said it has designed them to allow dry running, reduced the number of parts to simplify maintenance and inspection, and included wear-resistant hydraulics. Other features include the company’s Dura-Spin system to help flush abrasive materials away from the impeller neck, its Spin-Out design to protect the outer seal by removing abrasive particles, and use of a Hard-Iron impeller and suction cover to reduce wear and resulting downtime.

Speaking at the launch of the new BIBO range at this year’s bauma show, Xylem product manager Daniel Westin said, “The reliability and capability of the original Flygt BIBO dewatering pump is renowned within the industry and set the standard for submersible dewatering when it was first launched in the 1960s. This design forms the core of the new generation of BIBO pumps, which now includes the most advanced pumping technology.”

The Danish Mining Technology Group

Formerly known as the Danish Mining & Quarry Group, the Danish Mining Technology Group (DMTG), represents highly skilled companies servicing the global mining industry, including consultants, service providers, suppliers and subcontractors.

Denmark is home to a large number of highly specialized companies that focus on producing effective equipment and solutions for the international mining industry. Many of these companies are among the world leaders in their fields. Some are focused on traditional core mining technology, while others offer ancillary services.

Their success in the mining industry originates from centuries of developing cutting-edge solutions and know-how for business areas where Danish producers have taken a global lead—for example, in renewable energy and offshore oil and gas. The many years of experience they have accrued have been diversified into the mining sector, which is why Danish suppliers are represented worldwide in the mining industry today.

The DMTG provides a shortcut to key suppliers. Its members service both mining companies and OEMs worldwide, providing innovative high-quality equipment, services and solutions.

The DMTG is part of the Danish Export Association, giving it access to a large pool of expertise. More information about the organization, together with a full membership list, can be found at www.dk-mining.com.