E&MJ looks at the latest equipment for powering crushers, conveyors, pumps, fans, hoists and much more.

By Simon Walker, European Editor

Electric motors are the workhorses of any industrial operation, with mining and mineral processing being no exception. From the most powerful, driving hoists, crushers and mills to the smallest fitted to equipment such as reagent dosing pumps, motors keep the process moving.

In consequence, reliability is absolutely essential; a failed motor or drive on a critical component can, in a worst-case situation, stop the entire system in its tracks, and even where redundancy is designed in, a proportion of the process capacity will be lost until the problem can be fixed.

Where a big machine is involved, the impact can be severe: as Newcrest Mining reported last year, the discovery of loose windings in the motor driving one of the SAG mills at its Cadia operations led to the mill being out of action for several weeks. While investigations into the problem were under way, Newcrest decided to install a new conveyor to bypass the mill temporarily, with the final verdict being that a full motor rewind will eventually be needed as part of the mill maintenance program. Clearly, the situation could have been worse, especially if it had been deemed that running repairs were insufficient to keep the unit running while long lead-time parts were being sourced.

For this review, E&MJ asked several major suppliers of motors and drives for information about the systems they offer for different static applications.

What is the Application?

What is the Application?

Toshiba products for the mining and minerals industry include induction, wound rotor and synchronous motors, UPS, process and intelligent controls, motor controls, and power distribution protection solutions. The company reported that it has supplied mining operations throughout North America and South America, as well as in Australia.

Toshiba explained that although motors may appear to be the least complicated component of mining equipment, applications require unique analysis of the location, operational behavior and conditions to define the features for long motor life correctly. Mining requires rugged, durable motors for continuous operation that are relatively maintenance-free and are designed to operate safely and efficiently in hazardous and severe conditions.

Basic motor specifications begin with determining the often unique requirements of the application. For instance, is the application shaft-up with heavy belting conditions, as often found in flotation or separation processes, or is it for high-torque, high-power connected motors for high-pressure grinding rolls? Does the motor require constant torque and horsepower or does it cycle on a regular basis around the clock?

To select an induction motor correctly for a mining application, the speed vs. torque curve requirements of the driven equipment should be understood. For example, a particular motor may operate well on a centrifugal pump application, but will be unable to bring a full gyratory crusher up to speed because of the different starting torque requirements.

Toshiba’s product lines for mining-industry use include its general purpose EQP Global motor series, which is available in sizes from 0.75 hp to 500 hp. Designed for heavier work in sizes from 1 hp to 600 hp, the company’s Quarry Duty motor has a totally enclosed fan-cooled design and provides high starting torque, with oversized superior-grade roller bearings, and shafts built with high-strength 4142 steel to withstand the harsh working conditions.

For applications in potentially hazardous atmospheres, Toshiba’s explosion-proof motors (0.75-300 hp) are totally enclosed and are equipped to contain an internal explosion as well as to prevent emissions.

The company claims that its mediumvoltage motors are some of the toughest available, meeting the industry’s need for better reliability and energy efficiency. Completely customizable, they are available in open drip-proof, weather-protected type I and II, totally enclosed fan-cooled, and totally enclosed air-to-air cooled enclosures, in sizes from 100 to 50,000 hp (75-37,285 kW) and for voltages from 2,300 to 13,800 V.

Drives for Excavators

Drives for Excavators

With its headquarters in Indiana, Flanders specializes in excavator-duty motors designed specifically to withstand the harsh applications inherent to draglines and electric rope shovels. According to Mike Casson, responsible for global business development for surface mining, there are now hundreds of Flanders’ motors in service worldwide, including AC induction motors, AC synchronous motors, DC motors and generators, and complete high-output motor-generator (MG) sets.

Casson went on to note that one of the company’s most popular dragline upgrade products is its M series of motors for hoist, drag, and swing applications, which provide significantly increased thermal capacity and commutating ability for increased rope speeds. With the industry focus of increasing dragline productivity to minimize cost/m3, these motors are often the most cost-effective option available for achieving maximum dragline production, he claimed, currently being in operation in both North and South America, Africa, and Australia.

Flanders specializes in upgraded dragline rotating apparatus, offering a variety of dragline options to meet the specific needs of the end user based on increased reliability and improved dragline performance. The company not only manufactures new replacement apparatus for original DC equipment, and the M series of motors, but has also designed a line of high-output MG sets and the 1,000 series of AISE spec-based DC motors.

The MG sets coupled with the 1024 and 1022 frame hoist and drag motors were designed about 10 years ago, Casson said, specifically for dragline customers who were seeking significantly higher rope speeds and bail pull, but were not yet ready to take the leap to an AC dragline conversion.

AC has inherent advantages over DC with lower maintenance costs, higher efficiency, increased performance capability, increased safety, and lower ambient noise levels in the machine house. An AC dragline conversion is no longer a new, unproven concept, as Flanders has now converted three walking draglines from DC to AC, using its in-house designed active front-end (AFE) drive system. The latest of these was a Marion 8200, which has been in successful operation since May 2014, while the machine with the company’s first AC retrofit has now been working for more than five years.

Outside of motors and drives for mining equipment, Flanders also designs and manufactures large, special-purpose motors for minerals processing. An example is the company’s 7,000-hp (5.2 MW)/200 rpm synchronous motors, two pairs of which were designed and built to power two large SAG mills.

Spanish Specialization

Spanish Specialization

The Spanish company, Ingeteam, specializes in the development of electrical equipment such as motors and frequency converters. The company mainly serves sectors such as energy, mining, industry, marine and rail traction, seeking to optimize energy consumption whilst maximizing generating efficiency. Its mission is to develop in-house products that provide customized solutions for the specific application involved.

For mining, Ingeteam stated that it is set to become a global supplier of comprehensive product solutions, featuring state-of-the-art power electronics and machines designed and manufactured with in-house technology to develop a complete electrical drive package. As a result, the company can offer everything from a single frequency converter to a complete drive-train package with rectifier transformer, frequency converters and motors, plus appropriate accessories.

For mineral processing, Ingeteam has developed applications for both new installations and the refurbishment and expansion of existing systems, for applications such as SAG and ball mills, and belt conveyors, as well as mine hoists.

Ingedrive SC is a containerized electrical room, housed in a standard 40-ft shipping container, that offers prefabricated, modular power control-room housing, with complete power distribution and control cabinets, as well as auxiliary systems such as HVAC, dust filter pressurization, fire protection and access control.

At this year’s Society for Mining, Metallurgy and Exploration (SME) Annual Conference and Expo, held in Phoenix in February, Ingeteam’s presentation, New generation variable speed drives: optimizing the grinding process in comminution circuits, highlighted the technical details of mining projects the company has undertaken worldwide. It also described drive solutions for ball mills and high-pressure grinding rolls, highlighting the advantages of speed variation for each application and explaining how to achieve a longer service life, as well as providing plant-specific details.

As an example, Ingeteam offers medium-voltage Ingedrive MV frequency converters, either as DFE-type diode rectifiers or as AFE-type regenerative rectifiers for mills and high-pressure grinding rolls from 800 kW to 18,000 kW. Benefits include the small footprint, a low parts count and excellent reliability, the company stated.

Power From TMEIC

Power From TMEIC

Established in 2003 through the merger of the industrial systems departments of Toshiba Corp. and Mitsubishi Electric Corp., TMEIC produces variable frequency drives, motors and advanced automation systems. Its mining industry applications include motors and drives for mine hoists and fans, pumps, grinding and SAG mills, conveyors, and draglines and mining shovels.

The company’s product range includes large, rugged three-phase medium-voltage electric motors, both synchronous and induction up to 100,000 hp

(74.6 MW), with multiple poles for ranges of speed, and designed for variable speed operation. It also offers high-power variable-frequency drives for soft-starting motors and for varying motor speeds, with power levels up to 80 MW (107,300 hp), operating on low- and medium-voltage power at voltages from 440 V up to 11 kV. Its special drives are used for controlling the speed of wound rotor motors, and for recovering slip power, while it supplies special controls for operating large drives, and services for the design of complete custom systems.

In February, TMEIC launched its TM21-G family of induction motors, for which typical applications include driving pumps, compressors, fans, conveyors

and mine hoists. The motors’ main features include good reliability, high efficiency, superior quality leading to long service life, and low maintenance, the company claims.

Standard features include frame sizes from 315 to 900 mm, with maximum output power of 30,800 hp (23 MW). Rated voltages range up to 11 kV. The maxi-

mum speed, operating from a variable frequency drive, is 3,600 rpm. Available enclosures and cooling systems include totally enclosed fan cooling, weather-protected Type II cooling, totally enclosed air-to-air cooling and totally enclosed water-to-air cooling, with the motors available with either antifriction or sleeve bearings.

The company lists the benefits of using variable-frequency drives in mining applications as including increased reliability over mechanical alternatives, significantly less maintenance and, for excavators, good speed and position control. They also offer better soft-starting characteristics for conveyor and mill motors, eliminating stress caused by starting inrush currents and providing extended motor life.

Industry-tough Hardware From WEG

With its headquarters in Brazil and operations worldwide, WEG offers a range of motor and drive products for mining applications. These include its W22 standard and crusher-duty motors, MV drives and EM synchronous motors.

The company stated that its goal for the W22 motor is high performance with maximum energy efficiency, while providing low lifetime ownership costs. Typical applications include powering pumps, fans, crushers, mills, presses, elevators and packaging equipment.

WEG Crusher Duty W22 motors are specifically designed to meet requirements for rock crushing applications. FC-200 grade cast iron provides superior strength and heat dissipation, while the motors are built with 4140 high-strength steel shafts. They are designed for vertical or horizontal mounting, and have exceptional high starting and breakdown torque, WEG claims. As well as being fitted to crushers of various types, these motors can also be used in applications such as grizzley feeders, belt feeders and conveyors.

The company’s MVW01 variable-speed drive is designed to control medium-voltage induction motors. It features unique innovations, combining hardware robustness with simplicity, reliability and safety in a compact solution with few components and state-of-the-art generation technology, WEG stated.

The company recently reported on a project it completed last year, involving the supply of two replacement synchronous mill motors for Grange Resources in Tasmania. WEG designed a motor specifically tailored to retrofit with the existing infrastructure of the old motor, providing a “drop-in fit” that allowed Grange to mount the new motors without having to redesign the existing foundations.

WEG engineered the new motors and the complete excitation system panel in Brazil, with the components being manufactured in India before being shipped to Tasmania for installation.

A New Name in Drives

The acquisition at the end of 2014 by Danfoss of the Finnish producer of AC drives, Vacon, led to the formation of Danfoss Drives. The company now supplies its VLT and Vacon drive technology for controlling mining and mineral processing equipment such as conveyors, feeders, slurry pumps, cyclone-feed pumps, tailings pumps, flotation cells, mine dewatering pumps and fans, crushers and screens, as well as large material-handling machines such as excavators, stackers, reclaimers and shiploaders.

The company noted that AC drives are increasingly being used to control equipment on mine sites efficiently. To protect them from the harsh environment, they are often installed in sealed switchrooms, but this in turn creates challenges as the more drives there are in a room, the greater the heat loads created. While this can lead to the need for higher-capacity air-conditioning systems substations, the unique back-channel cooling design of higher power VLT drives, and the availability of Vacon liquid-cooled drives can result in significantly reduced heat loads in switchrooms, enabling the use of smaller, lower-cost air-conditioning systems.

The sheer size of mining operations means that long cables are often needed between drives and motors. Both VLT and Vacon drives are designed to provide trouble-free operation with cable lengths up to at least 150 m (500 ft) for screened cables and 300 m for unscreened cables, saving space, installation time and costs compared to more traditional drive solutions, Danfoss pointed out.

Mine ventilation is one area where AC drives can save money, since fan costs often take up a major slice of a mine’s total power costs. According to Danfoss, AC drives are well-recognized for being the most flexible, energy-efficient and low-maintenance method for controlling both main and auxiliary fans, and can easily be integrated into ventilation-on-demand control systems.

The company cited one example where trials with a Vacon drive on one booster fan at an underground mine in Alaska produced savings that translated into around $100,000 based on the cost of on-site diesel generation, with the payback measured in months. The success of the trial led to the rest of the fans at the mine being equipped with Vacon drives.

Bosch Rexroth Offers an Alternative

Bosch Rexroth Offers an Alternative

With its range of Hägglunds hydraulic drives, Bosch Rexroth offers an alternative approach to electric drives for some applications. For mining, these can include conveyors, feeders, crushers and mills, as well as large-scale stockyard machines. Focusing on feeders, the company states that drive selection is extremely important for their function, which is to control the gravity flow of bulk solids.

Hydraulic drives, especially of the low-speed, high-torque type, are becoming more widely used on apron and belt feeders, which operate under severe conditions where there is often the need for high starting torque as well as frequent load spikes. While still less common than electromechanical drives, these systems can now be found in installations around the world, Bosch Rexroth noted.

The starting torque needed is a major factor when sizing feeder drives, with high shear forces increasing the starting torque by as much as 200% of the running torque when coarse rock is being handled. Hydraulic drives allow precise limiting of the maximum torque, protecting the feeder belts and chains, and no drive oversizing is needed to cope with the tough feeder starts, as is the case with electromechanical drives.

The company added that a further advantage of hydraulic drives is their handling of changes and differences in running speed. While small speed variations occur because of changes in material density or operating commands, major slowdowns can happen as a result of changes in material flow, or through blockages. Hydraulic drives can run constantly at any speed, from minimum to maximum, without overheating the electric motor. In addition, they provide built-in protection against shock loads, because of the hydraulic motor’s low moment of inertia.

Maintenance on hydraulic drives is also more straight-forward, since they are more compact than electromechanical designs and have fewer components. With a feeder needing just one electric motor and one pump, more than one drive can be used as well, providing a level of redundancy and safeguarding production.

ABB’s New Gearless Conveyor Motor

ABB’s New Gearless Conveyor Motor

While ABB provides a full product line of motors, transformers, variable frequency drives and other equipment to the mining industry, the company has chosen to highlight a new gearless conveyor motor for medium-powered conveyors. To be unveiled at this year’s bauma show, this will be a game-changer in conveyor drives design, it said.

In this case, ABB is classifying “medium power” as being conveyors in the 3- to 10-MW drive class. By eliminating gearboxes, and using a permanent magnet motor, ABB claims to have achieved more than 50% higher reliability and availability over previous designs, with more than 30% reduction in losses leading to what it said are the lowest operating costs available on a per-ton basis. Fewer components mean higher reliability with less maintenance needed, so equipment utilization rates are higher and production losses reduced, while the increased efficiency gives lower specific energy consumption. In addition, noise generation is lower than with traditional conveyor drives.

ABB explained that since conventional low-speed synchronous motors cannot meet all of the requirements for the new drive in the medium power range, an alterative type of motor was needed. The permanent magnet motor is light and compact yet capable of performing heavy duty in either foot- or shaft-mounted configuration. Air or liquid cooling is used, with no external cooling circuits needed. The compact design means that it can be easily installed either from new or as a retrofit option, with shaft mounting doing away with any need for alignment on site.

The company gives the example of retrofitting its new drives to an existing, 2-km-long belt conveyor travelling at 6.6 m/s and carrying 8,000 t/h. Gearboxes were eliminated without major structural reinforcement or modification, giving a reduction in the total weight of the drive section, while the total mechanical and electrical efficiency was increased from around 90% to 94%. The return on investment was given as two years.

Baldor’s Motor-gearbox Packages

Baldor’s Motor-gearbox Packages

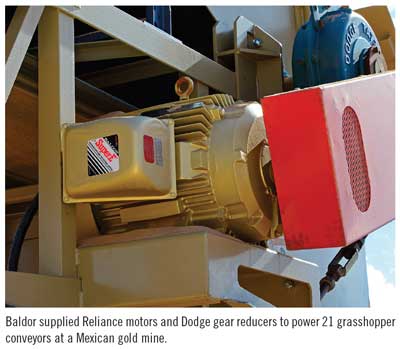

Also part of the ABB group, Baldor’s mining-sector products include its Reliance electric motors and Dodge reducers, fluid couplings and bearings. The company provided E&MJ with information about two conveyor projects for which it recently supplied drive systems.

At the first, for a steam-coal company in western Kentucky, Baldor drives were used on a new elevated conveyor for moving raw coal from the mine to a barge loadout, and on off-loading conveyors at the prep plant some distance away. The design called for a total of ten Baldor Dodge MagnaGear reducers, coupled to Baldor Reliance mining industry motors. The company describes the MagnaGear XTR as being a high-horsepower speed reducer—a compact, power-dense design in a heavy-duty package.

MagnaGear reducers are available in parallel shaft or right-angle configurations, with solid or hollow output shafts. They also come in several mounting configurations, including tunnel housings, with a universal housing design that helps users minimize spares stocks.

Meanwhile, in Mexico, Baldor provided Dodge Torque-Arm II reducers, S-2000 bearings and Mine Duty Extra pulleys, along with Reliance motors, for a series of 21 grasshopper conveyors used for ore stacking at a heap-leach gold mine. The mine also needed a drive capable of providing a soft start for a heavily loaded belt, 575 m (1,890 ft) long with a 69-m (226-ft) lift. For this, Baldor supplied a Dodge 920 MagnaGear right-angle reducer and a custom 375-kW (500-hp) totally enclosed, fan-cooled Reliance motor, with a Dodge fluid coupling to provide the soft start.

Turning to electric motors, Baldor’s Crusher Duty motor line is engineered for use in high-torque applications and harsh environments in the aggregate, cement and mining industries. The range encompasses 19 models offering outputs from 5 to 400 hp (3.7-298 kW), at base speeds of 900, 1,200 and 1,800 rpm.