Recent project changes a maintenance- and labor-intensive ‘nightmare’ belt line into a highly functional, dependable system

By Robert Stepper and Richard Shields

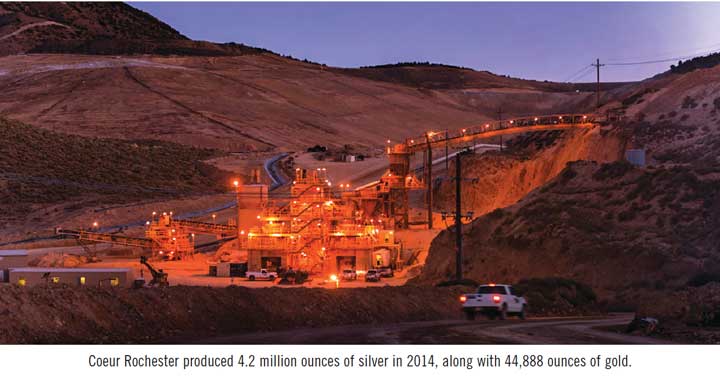

Coeur Mining Inc. is the largest primary silver producer in the United States and a significant gold producer, with three wholly owned operations in North America and two in Latin America. Incorporated in 1928, the firm currently employs around 2,000 people. The company’s Rochester mine and associated heap-leach facilities are located in Pershing County, Nevada. Coeur Rochester produced 4.2 million ouces (oz) of silver in 2014, along with 44,888 oz of gold, and the firm estimates that it expects a yield of nearly 5 million oz of silver and more than 50,000 oz of gold in 2015.

The firm’s business strategy is to develop and operate low-cost silver and gold operations that will produce long-term cash flow and generate sustainable returns, but the company operates with a deep commitment to its code of corporate responsibility to employees, contractors, communities and the environment.

“Our primary commitment to employees and contractors is to protect their health and safety,” said Coeur President and CEO Mitchell Krebs. “Safety programming and management systems are continuously reviewed and improved to provide the training and tools necessary to prevent accidents, injuries and occupational illnesses.” That code is evident in the facility’s safety record: more than six years and counting without a single lost-time injury (LTI).

As part of that commitment of corporate responsibility and continuous improvement, Coeur Rochester recently undertook a comprehensive review of its bulk material handling processes. The massive Rochester site is spread over 10,800 acres (43.7 km2), and includes a network of 20 conveyors, originally designed and installed in 1986. Given the system’s age and the amount of usage over nearly 30 years in service, company officials began considering ways to update the conveyors with leading-edge technology to raise efficiency, reduce dust and spillage, and contribute further to safety.

Coeur managers initiated discussions with HARDROK Equipment, a supplier with more than 40 years of combined experience in maintaining and optimizing crushing, conveying and screening operations. The teams met and did a thorough review of the entire conveyor network, followed by a series of five training sessions to review the issues and the technologies available to resolve them. HARDROK is a licensed dealer of Martin Engineering conveyor products, and much of the discussion revolved around the company’s EVO Conveyor Architecture, a literal reinventing of the conventional design approach for conveyors.

“We’ve always operated under the belief that high-quality products and services cost less per ton over the life of the product,” said HARDROK President Ted Zebroski. “With proper design, premium components should improve productivity and safety, and that greater efficiency delivers a lower total cost of ownership.”

During plant construction, most conveyor systems have been specified by determining the capacity and meeting the minimum codes and safety requirements, with a focus on the lowest construction cost,” Zebroski said. “Instead, the Martin EVO approach examines every detail for opportunities to make conveyors safer, more productive and better able to contain fugitive material. And the concept can be applied to new systems or retrofitted to existing designs.”

Conveyor B was chosen as the starting point with the most potential for improvement—48-in.-wide (122-cm) belt running at 386 ft/min, with a 40-ft (12.2-m) chute wall. With a troughing angle of 35°, Conveyor B handles nearly 1,500 tons per hour (t/h) of rock that has been sized to 4-in. (10.2-cm) minus, carrying it from the secondary cone crusher to the surge pile stacker. It’s loaded directly by a vibrating grizzly feeder under the chute and the secondary crusher.

“There’s a long fall going to the secondary crusher, and that creates a huge disturbance in the material flow,” explained Crusher Operations/Fixed Plant Maintenance Superintendent Wayne Maita. “We were seeing a lot of dust and spillage in that area. It not only affected the air quality and presented a potential safety risk from accumulated material on floors and structures, but it also meant putting operational personnel in close proximity to the moving conveyor for cleanup.”

“There’s a long fall going to the secondary crusher, and that creates a huge disturbance in the material flow,” explained Crusher Operations/Fixed Plant Maintenance Superintendent Wayne Maita. “We were seeing a lot of dust and spillage in that area. It not only affected the air quality and presented a potential safety risk from accumulated material on floors and structures, but it also meant putting operational personnel in close proximity to the moving conveyor for cleanup.”

Coeur also noticed belt damage occurring as a result of fugitive material. “As material escapes, it accumulates on idlers and other components, often creating friction points that contribute to excessive wear and premature failure,” said Martin Engineering Product Engineer Daniel Marshall. “That can have immediate costs such as belt replacement and seized bearings. And once an idler freezes, the constant belt movement can wear through the shell with surprising speed.”

Maita estimated that dealing with the spillage required 5 to 10 man-hours per day, seven days a week. So in addition to the safety aspect of the fugitive material, there was a significant cost in wasted labor. “We pay our guys to be operators, not to sweep and shovel spilled material,” he said. “That time is better spent on core business activities.”

The proposal for Conveyor B included a number of upgrades to eliminate belt sag, provide effective edge sealing and remove dust from the material stream, while withstanding the heavy loads and near-constant usage. Specific components were recommended for durability under the heavy load and impact at the transfer point.

A team of eight technicians from HARDROK and two Martin supervisors began work during a scheduled outage, starting by leveling out the conveyor structure and adding 4×4-in. (10.2 x 10.2-cm) angle iron reinforcement as needed to straighten out the belt path. They removed existing clamps, skirt seal, skirt boards, belt support components and belt cleaner assemblies, and modified the inlet chute to accommodate a new containment system and provide a clean, flat surface at a CEMA standard width.

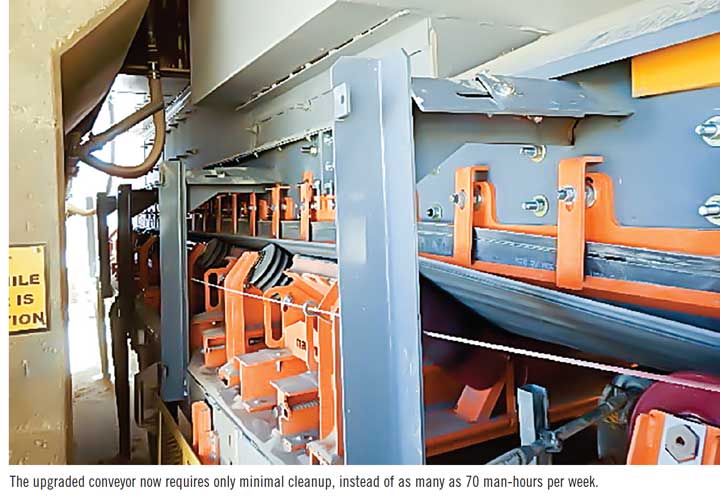

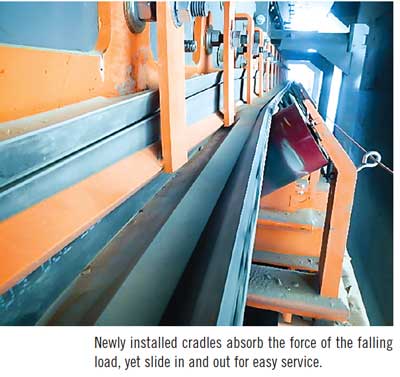

Five Martin EVO Combination Cradles were then installed to absorb the impact of the falling load, while minimizing friction and belt wear. The design features steel-reinforced impact bars and adjustable wing supports to match standard trough angles of 20º, 35º or 45º. Instead of the full layer of support bars that appear on a true impact cradle, the Combination Cradle replaces the center bars with an impact idler roll, a design that delivers a flat surface for an effective edge seal, but minimizes the friction of having sliding bars all the way across. Eccentrics built into the supports also deliver 5° of wear adjustment, so the alignment between wings and idlers can be optimized for effective transfer point sealing.

The cradles employ Martin Engineering’s Trac-Mount technology, allowing the units to slide in and out easily for maintenance or replacement. The modular components are light enough to be removed by one person, without using heavy lifting equipment. “Conveyor downtime is extremely expensive, especially for high-speed operations,” Marshall added. “The longer components last and the easier they are to replace, the lower the cost of ownership.”

Technicians also installed five EVO Slider Cradles with low-friction bars to support the belt edges and stabilize the belt line, eliminating belt sag and bounce. The Slider Cradles are also track mounted for ease of installation and maintenance. Located in the chute box after the impact cradles, the units feature “double-life” slider bars, which offer a superior seal with low friction. The proprietary box design allows each bar to be flipped over at the end of its useful life to provide a second wear surface. The result is a flat and stable belt surface throughout the settling zone, reducing fugitive material and extending belt health.

Forty feet (12.2 m) of modular chute wall was used to replace the old structure, with a tail box and integrated dust curtains. A chromium carbide overlay on the inside protects the new containment system from intermittent high-burden depths on the conveyor.

The chute was then fitted with an abrasion-resistant external wear liner, another design upgrade. Previous wear liner designs were welded to the inside of the chute, with only the skirt seal located on the outside. The logic behind this conventional design is for the wear liner to protect the skirtboard, which is typically ¼-in.-thick (0.64-cm) sheet metal and is not strong enough to withstand the sustained force and abrasion from bulk material.

The wear liner is essentially a sacrificial layer, and the eventual removal/replacement of this design typically requires confined space entry, multiple workers and days of downtime. Instead, Martin Engineering designers came up with the idea of raising the chute work about 4 in. (10.2 cm) above the belt, then putting the wear liner on the outside. Using this approach, the material still hits the liner and doesn’t damage the chute. The result is significantly reduced installation and service time, with reduced risk during service.

At the bottom of the wear liner is mounted 84 linear ft (25.6 m) of Martin ApronSeal Double Skirting, which delivers two wear surfaces on a single elastomer sealing strip. When the bottom side of the strip against the belt is worn, the sealing strip is inverted, providing a second service life. The design was the first dual-sealing system for belt conveyors, incorporating a primary seal clamped to the steel skirtboard to keep lumps on the belt and a secondary or “outrigger” strip to capture any fines or dust particles that pass beneath the primary seal. The secondary seal lies gently on the belt and self-adjusts to maintain consistent strip-to-belt pressure, despite high-speed material movement and fluctuations in the belt’s line of travel.

At the bottom of the wear liner is mounted 84 linear ft (25.6 m) of Martin ApronSeal Double Skirting, which delivers two wear surfaces on a single elastomer sealing strip. When the bottom side of the strip against the belt is worn, the sealing strip is inverted, providing a second service life. The design was the first dual-sealing system for belt conveyors, incorporating a primary seal clamped to the steel skirtboard to keep lumps on the belt and a secondary or “outrigger” strip to capture any fines or dust particles that pass beneath the primary seal. The secondary seal lies gently on the belt and self-adjusts to maintain consistent strip-to-belt pressure, despite high-speed material movement and fluctuations in the belt’s line of travel.

To maintain a straight and consistent belt path, technicians then installed a Martin Heavy-duty Tracker Belt Tracking System, both upper and lower units. Utilizing innovative multiple-pivot, torque-multiplying technology, the tracker detects slight misalignments initiated by unbalanced loads and fouled rollers, using the force of the belt to immediately adjust its position and realign the path.

Rollers attached to the end of a sensing arm assembly ride both sides of the belt edge, detecting even slight variations in the belt path. Employing the force of the wandering belt, the arms automatically position a steering idler in the opposite direction of the misalignment. Transferring the motion to the steering idler through a unique parallel linkage requires less force to initiate the correction, so fine-tuning of the path can be continuous, active and precise.

To address belt carryback and further reduce the chance of fugitive material, a dual belt cleaner system was mounted on the face of the head pulley. The primary unit is a Martin QC1 Cleaner XHD, which is engineered to deliver durable belt scraper performance in challenging applications. Designed for high belt speeds and multiple splices, the unit’s patented Constant Angle Radial Pressure (CARP) design maintains cleaning performance through all stages of blade life. The rugged 3/8-in. (95-mm) steel tubing main frame has a steel bar backbone, and an aluminum extrusion in the base holds the cleaner snugly in place.

Directly after the primary cleaner is a Martin DT2 Inline Cleaner XHD, a secondary conveyor belt scraper featuring blades installed on a track that slides into position on a rigid steel mandrel, which allows quick blade replacement to increase the conveyor’s availability. The design’s individual belt cleaner blade segments slip into a sturdy track-forming cartridge, which slides over the stainless steel mainframe for simple installation.

A final belt protection mechanism was installed at the tail pulley. To fight the potentially damaging effects of fugitive material on the return side of the belt, the Martin Torsion V-Plow is engineered with a unique spring-loaded suspension system that allows the plow to rise and fall with fluctuations in belt tension and travel. Attached with dual steel crossbars bolted to the conveyor frame a few feet from the tail pulley, the unit is secured by two heavy-duty safety cords. Three torsion arms adjust independently, maintaining consistent pressure for effective cleaning in all stages of blade wear.

“Bulk material bounces when it comes in contact with a fast moving conveyor and often shifts as it travels over carrying idlers,” explained Marshall. “These disturbances can eject small amounts of material from the belt. Occasionally along its return run, the belt will collect lumps of spilled material on the non-carrying side. If these objects are not removed, they can become trapped between the tail pulley and the belt and do significant damage to both.”

To complete the containment system, technicians also installed an integrated air cleaner, which contains a suction blower, filtering elements and a filter cleaning system. Instead of a centrally located unit connected to dust generation points via ductwork, the Martin Air Cleaner is incorporated into the dust generation point itself. The particles are not extracted, but are instead collected within the enclosure and periodically discharged back into the material stream. Unlike central systems, the integrated approach employs a smaller, independently operating unit directly at the dust generation point.

The integrated air cleaner contains an apparatus to clean the filters using a pulse of compressed air. As material is captured by the filters, it agglomerates against the filter media. When the filter media is pulsed, the material will fall. If it is agglomerated and large enough, it will fall back into the material stream. The pulse system is designed to alternate pulses to each filter element. When one filter is being pulsed, the adjacent filter is still drawing air. If a pulsed particle is too small to drop out of the air stream, it is immediately pulled into an active filter.

Like the central system, integrated units use negative pressure, with airflow created by a blower sized to provide the airflow needed for the pickup point. As there is no ducting, there are no pressure losses other than the filters that must be accounted for. Because of this, the power requirements of an integrated air cleaning system are far lower than for central collection systems.

The entire upgrade was completed within a seven-day shutdown, and the results were immediately apparent. “We’ve gone from an everyday battle with this conveyor to almost no cleanup at all,” said Maita. “We have a guy go down there with a broom every few days. That’s it.”

Coeur Rochester is currently evaluating five additional conveyor areas for its next upgrade, with a plan currently under development to address those locations in 2016. “We’re extremely happy with the system,” Maita concluded. “The installation was well done, and the guys were very professional and safety-conscious. It’s changed a nightmare into an extremely functional system that operates at a high level.”

Robert Stepper is general manager, Coeur Rochester operations. Richard Shields is western regional manager, Martin Engineering.