A new diagnostic reliability service from Rockwell Automation helps mine and other industrial plant operators drive a streamlined maintenance strategy on mission-critical, integrated equipment lines.

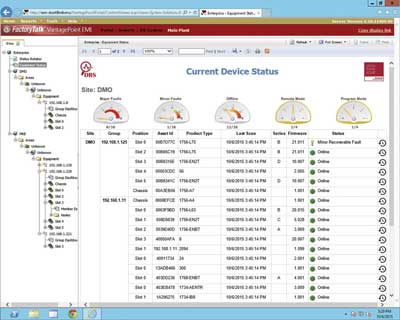

The solution deploys a layer of technology across plant devices and equipment to monitor and perform analysis, and create a continuous improvement approach to reliability maintenance, reducing operational risk. It automatically collects identity and health data from all networked devices on the production control network. The data is then modeled with asset management information to trigger events and send alerts to necessary personnel for proactive maintenance. With the service, Rockwell Automation asset reliability professionals assist users in applying the intelligence on their critical equipment to inform data-driven maintenance decisions and increase productivity. According to the company, through integrated, automated device identification and tracking, customers using the diagnostic reliability service can realize approximately 70% reduction in manual data-collection time.

The solution deploys a layer of technology across plant devices and equipment to monitor and perform analysis, and create a continuous improvement approach to reliability maintenance, reducing operational risk. It automatically collects identity and health data from all networked devices on the production control network. The data is then modeled with asset management information to trigger events and send alerts to necessary personnel for proactive maintenance. With the service, Rockwell Automation asset reliability professionals assist users in applying the intelligence on their critical equipment to inform data-driven maintenance decisions and increase productivity. According to the company, through integrated, automated device identification and tracking, customers using the diagnostic reliability service can realize approximately 70% reduction in manual data-collection time.