|

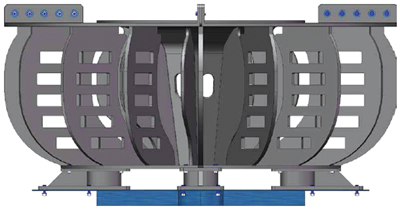

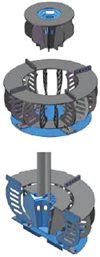

| FLSmidth says its new nextStep rotor/stator for forced-air flotation cells (shown here in cutaway and assembled views) offers up to 5% better recovery rates and 10%-15% lower power consumption than other mechanisms. |

FLSmidth launched its new nextSTEP rotor/stator at a major industry exposition in February, explaining that the technology represents a “step change” in forced-air flotation metallurgical performance and energy efficiency.

“After years of flotation research and development, where we tested more than 200 rotor/stator combinations, we developed the optimum solution that delivers significant improvements in performance of forced-air mechanisms. The nextSTEP rotor/stator has the lowest operating power of any forced-air flotation mechanism on the market. Additionally, this new technology demonstrates dramatic improvements in attachment rates, stronger air dispersion and improved pumping efficiency, which leads to increased recovery,” said Frank Traczyk, FLSmidth’s global flotation technology director.

FLSmidth has been field-testing the new nextSTEP rotor/stator at several installations, including the previously announced FLSmidth 600-series Supercell flotation site in Nevada, currently the largest operating flotation cell in the world.

FLSmidth has been field-testing the new nextSTEP rotor/stator at several installations, including the previously announced FLSmidth 600-series Supercell flotation site in Nevada, currently the largest operating flotation cell in the world.

“It’s very exciting to see that the actual operating performance exceeds the aggressive goals we set for this development project over four years ago,” Traczyk said. “We designed the rotor/stator to not only outperform the competition when it comes to recovery, but to also do it more efficiently, using less power; and that’s exactly what we accomplished with the nextSTEP mechanism. This will be very attractive for mineral processing plant customers who rely on forced-air flotation systems.”

The company plans to offer the new flotation solution globally. It is designed to be interchangeable with existing FLSmidth forced-air flotation mechanisms, and can also be retrofitted into any existing forced-air flotation cell, according to the company.

FLSmidth has delivered more than 56,000 flotation machines in total, varying in size from 1 m3 up to 660 m3, and including both WEMCO self-aspirated mechanisms and Dorr-Oliver forced-air mechanisms. The company also offers metallurgical testing, process design and field support.