For more than 30 years, the Hilliard Corp. has supplied braking systems for draglines, electric shovels, conveyors, mine hoists and mills. Now, the New York, USA-based company is set to unveil new caliper brake systems it has developed, tested and certified on its own. These new products, according Rick Kallenborn, regional sales manager for Hilliard, will replace existing systems with a standardized product that is more user-friendly and will allow mine operators to reduce parts inventories.

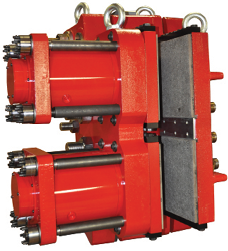

Hilliard’s M900 ball mill brake, part of its extensive product line of brake units for grinding mills, conveyors and large excavators.

“We have made a lot of modifications to improve longevity and the ease of operation, using what we have learned over the years to correct the problems that these systems sometimes encountered while operating,” said Ben Heater, engineering product manager for Hilliard. “The Hilliard engineers that developed these braking systems are the same engineers that spent years servicing them in the field.”

Mark Rose, marketing manager for Hilliard, explained that, “In 2007, Hilliard started to consider new designs and improvements for brakes that no other manufacturer offers,” Rose said. “We thoroughly tested these units during

the past several years and we are preparing to introduce them to the market in September.”

“We have performed 200% load testing on our brakes,” Heater noted. “We’re pushing a million cycles at 100% of their maximum force or more on these brakes and we know the failure points and how long these brakes will physically operate.”

The harsh environment and extremely high loads often encountered in mining applications can push braking systems to the limits. Eventually the system’s seals begin to leak and then the brakes fail. “We want to eliminate these catastrophic failures,” Kallenborn said. “We have implemented several modifications to improve maintenance. These new systems are interchangeable with the old systems. The mounting configurations and the footprint are the same. The arm kits replace the ‘left’ and ‘right’ arms with one standardized arm. The changeover can be implemented quickly.” Quicker repairs mean less downtime for maintenance, he explained.

Hilliard is confident these new systems will appeal to mining operations. “The most exciting aspect of this is that we are now able to control our own fate with these brakes,” Heater said. “We know how these brakes are made and what applications they can handle. We are standing behind our own product.”

Hilliard said it has invested in its manufacturing capacity in order to reduce lead time and it can custom design a braking system for any application the mining industry needs.

Metso to Help Codelco Take Chuquicamata Underground

Metso announced in mid-August that it had won a large contract to support the conversion of Chuquicamata—the largest open-pit copper mine in the world—to a large-scale underground mining operation. The mine, located 1,650 km north of Santiago, Chile, is owned and operated by Chilean copper producer Codelco.

Metso’s role in the project award includes the engineering, supply of equipment and materials, and site assistance for 12 underground crusher stations combined with a conveyor package. The delivery contains 11 new units of Metso’s largest C200 jaw crushers, 24 push feeders and 20 conveyors. Overall, the contract constitutes one of the biggest crusher orders ever for Metso’s mining business. The project is scheduled to continue until 2020. The value of the contract was not disclosed.

Metso said it offered Codelco an integrated solution that carried through from engineering, crusher stations, and material handling to electrification, automation, and site assistance. Future savings from its Energy Saving Idler (ESI) conveyor technology also contributed to the offering’s competitive edge, according to Metso.

George Fisher Mine Chooses Modular’s DISPATCH FMS

Modular Mining Systems’ DISPATCH Underground 2015 fleet management system (FMS) has been selected for implementation at the George Fisher mine in northern Queensland, Australia. The underground lead-silver-zinc mine, which forms part of Glencore’s Mount Isa copper and zinc mining complex, first began production as the Hilton mine in 1990 and today has an annual production rate of 3.1 million metric tons.

Chris McCleave, general manager of the George Fisher mine, said, “With the implementation of Modular’s DISPATCH Underground system, we ultimately hope to improve productivity through increased equipment availability and improved utilisation of mobile assets, while also positively impacting operator safety.”

According to Modular, its DISPATCH Underground FMS, originally introduced in 1991, delivers a scalable, highly configurable end-to-end solution that provides automated, real-time monitoring, management and visibility of underground mining operations. DISPATCH Underground 2015, released in May 2015, is the latest version of the system and supports all development and production workflows and activities, enabling mines to maximize material movement, reduce mining costs, and effectively manage their mining processes.

Greg Sweeney, general manager, Modular Australia, said, “With Modular’s underground technologies in place, the mine stands to realize greater fleet utilization and increased production gains through a reduction in delays during shift change, breaks and other activities.”

The mine will use DISPATCH Underground on its fleet of LHDs and underground mining trucks. System implementation is expected to begin later this year and will be rolled out over an extended project period.

Xylem Opens New Pump Rental Hubs in South America

Xylem is expanding its dewatering pump rental and service capabilities across Latin America, launching three new hubs in the region during 2016. The company opened its newest dewatering pump rental facility in Barranquilla, Colombia, following similar openings in Pará, Brazil, and Chiclayo, Peru, earlier this year. These new hubs join six other dewatering pump rental hubs that Xylem has opened in the region over the past six years as part of a multimillion dollar investment in Latin America.

The company said its new Barranquilla hub won a contract to deliver 14 HL260M Godwin high-head diesel dewatering pumps to a mine in northern Colombia. The pumps will be used at the mine in anticipation of the La Niña weather pattern bringing significantly increased rainfall to Colombia starting in August and continuing through to the spring season. The pumps will be interspersed throughout the mine at 250-m elevations, continuously pumping to keep the mine dry.

“Xylem’s expanded rental hub network across Latin America will allow us to quickly address our customers’ water challenges, moving large, powerful rental pumps and equipment to wherever they are needed across the region,” said Osvaldo Greco, managing director, Xylem Latin America.

Air-operated Hoists Handle Extreme Conditions

Rarely a shift goes by in any mine—surface or underground—without an urgent need for a heavy item to be quickly and safely lifted, shifted or tugged. J D Neuhaus GmbH & Co. KG, a German supplier of industrial hoists and cranes, pointed out that its Profi TI range of air-operated hoists have successfully proved their versatility and reliability in service at a wide range of industrial workplaces. According to JDN, these hoists have been engineered for extremes and can be safely operated within hazardous working environments. Using a compressed air supply for both power and control functions, the Profi TI hoists contribute to greater overall safety, eliminating sparks generated by static discharges or metal-to-metal friction contacts.

The Profi TI hoist range provides lift capacities from 250 kg up to 100 metric tons. The operating air supply can be set at 4 or 6 bar pressure, with a standard load lift height of 3 m. Custom lift height requirements also can be specified and accommodated.

JDN said its hoists are used in many mining applications, such as for withdrawing shield supports and other heavy equipment at the face and in galleries; for crane installations in workshops; and to handle shaft sinking equipment, along with general lifting, pulling and tensioning jobs. Its M Series hoist line was developed specifically for underground mining operations, offering most of the same features as the Profi series, but operating with an air pressure of only 4 bar. These hoists are suitable for use in hazardous areas with risk of explosion (ATEX I M2), offer two chain falls for alternate working, and are designed to facilitate horizontal load movements.

Overall, Profi TI hoists are 100% duty rated with unlimited duty cycles, minimizing downtime. Their compact design eliminates protruding control hoses or similar external parts susceptible to damage, adding to their suitability for even horizontal pulling. Standard hoists are insensitive to atmospheric dust or humidity and withstand working temperatures ranging from -20°C to +70°C. A low maintenance vane motor brake system ensures fail-safe starting and positive braking, while providing lube-free operation. Various pendant controls can be fitted for sensitive, single speed, multifunction or remote control operation.

Hydraulically operated versions of the JDN Profi range are also available, together with hoists specifically designated for operation within unique working conditions. The hydraulic hoist line offers carrying capacities up to 50 mt.

J D Neuhaus’ Profi TI hoist range provides lift capacities from 250 kg up to 100 metric tons. Its M Series hoist line is intended specifically for underground mining operations, offering most of the same features as the Profi series.

Joint Effort to Improve Mine Ventilation Solutions

Maptek and VUMA, a subsidiary of Bluhm Burton Engineering (BBE), have executed a memorandum of understanding for collaboration and cooperation around mine ventilation solutions and mine design. The primary focus will be on enabling detailed data transfer between Maptek Vulcan mine planning software and VUMA ventilation simulation software.

VUMA’s software enables analysis of underground mine ventilation, contaminant tracking, refrigeration and cooling networks. VUMA, a South African company, said its product allows heat engineering balance to be examined in detail, taking into account all factors contributing to heat load, including equipment, advance rates, heat from broken rock and mine design.

Vulcan software provides advanced underground mine design, planning and scheduling tools. Enabling detailed design, survey and operational data to be transferred to VUMA software is claimed to deliver valuable gains in accuracy, efficiency, and speed for analysis and planning around ventilation and refrigeration in underground mines. This also allows ventilation factors to be considered earlier in the mine planning process.

“VUMA is an impressive software suite. Integrating VUMA with Vulcan offers huge benefits to mine planning departments,” said Nick Venter, Maptek Africa’s general manager.

“It will allow mine survey and design data to be used in ventilation and cooling analysis, without replication of data, and ensures accurate, current representations of the mine surface can be applied to ventilation planning.”

VUMA3D-Network diagram of a gold mine ventilation system.

Articulated Truck Line Marks 50 Years of Haulage

The articulated dump truck (ADT) concept celebrates its 50th anniversary in 2016, marking half a century of transporting materials over rough, muddy, slippery, steep or otherwise impassable terrain. Volvo Construction Equipment, the company that commercially launched the concept in 1966, still claims market leadership in this sector, and has continued to innovate with the launch this year of its H-Series range, which includes its biggest ever production articulated hauler, the 60-ton-capacity A60H.

1966 was a turbulent year—the USSR’s Luna 9 made the first rocket-assisted landing on the moon, the Cultural Revolution began in China, England won the World Cup, and the Rolling Stones rock band was banned from 14 New York hotels. With so much going on, it may have been easy to overlook the launch of the DR631, marking the birth of the ADT. Essentially, that truck was a combination of an agricultural tractor (which Volvo then made) and a trailer, permanently joined via an articulating hitch and with the front axle of the tractor removed. Nicknamed “Gravel Charlie,” it could manage only a 10-ton payload, and its popularity grew slowly with early sales confined to the Swedish market.

One year after its launch, the company introduced the DR860, the first ADT with a bogie, allowing the material being carried to remain level and stable to reduce spillage as the wheels coped with highly uneven road surfaces. The first hauler with a turbo-charged engine, the DR860T, arrived in 1970 and in 1979, the launch of the 5350 introduced a truck capable of 50 km/h—a top speed previously unheard of—via its suspended front axle and an automatic transmission. Traction was further increased with the addition of a six-wheel-drive system. The A20 was launched in 1986 with a 200-hp engine and a 20-ton payload rating, followed in 1987 by the 35-ton A35, which featured a retarder built into the transmission to reduce wear on the service brakes.

The range was given a major overhaul in 1993 with the introduction of the C-Series, which included a low-emission engine, fully automatic transmission and 100% differential locks. The A40 40-ton class hauler was launched in the mid-1990s, with a 400-hp engine and oil-cooled wet disc brakes.

Volvo CE’s D-Class articulated haulers entered the market in 2000, covering a payload range of 24 to 37 tons. For the first time, diagnostic electronics were integrated into these models to alert both operator and technician of problems. Developments such as Automatic Traction Control (ATC) relieved the operator from having to manually activate differential locks and drive configurations as driving conditions changed. Multiple sensors checked the speed differences within the driveline and selected the best drive combination for the conditions. These features, according to Volvo, reduced tire wear, driveline stress and fuel consumption.

In 2007, Volvo CE introduced hydraulic suspensions with automatic leveling and stability control on all wheels. The Full Suspension variant allowed the truck to travel at much higher speeds even when fully loaded, without bouncing and rolling. These benefits, according to the company, increase with the length of haul road, effectively absorbing all rough spots and allowing operators to maintain considerably higher average speeds with or without a load. A hauler traveling at 55 km/h over rough haul roads was now possible.

The F-Series arrived in 2010, comprising haulers that met the standards demanded by Tier 4i (US) and Stage IIIB (Europe) emissions legislation, and also featured a package of improvements in functionality, design and maintenance. The F-Series now included the company’s CareTrack as standard—a telematics system that enabled remote monitoring of a wide range of machine functions (e.g., location, fuel consumption, service reminders, etc.).

The G-Series debuted in 2014, meeting Stage IV/Tier 4 Final emissions regulations and bringing new features. The oil-cooled wet multiple-disc brake concept used on the A35 and A40 models was added to the A25G and A30G. Larger models in the range were also offered with Volvo’s onboard weighing system, which tracks weight and relays information to software integrated into the machine’s electronics. Indicator lights tell the hauler operator, as well as the operator of the loading unit, whether the hauler is at part or nominal load or whether it has been overloaded.

The H Series, launched earlier this year, is Volvo CE’s answer to a growing demand among customers for articulated haulers with larger payloads. This series includes the 60-ton (55-mt) capacity Volvo A60H—which the company claims is the largest articulated hauler of any brand to hit the market.

Volvo CE said the A60H’s higher payload, representing a 40% increase over its previous largest hauler, significantly lowers the cost-per-ton ratio for customers—and also offers a viable alternative to rigid dump trucks in conditions involving soft, uneven ground and/or steep roads, allowing a similar amount of material to be hauled in a shorter cycle time.

From the oldest to the newest: Volvo Construction Equipment’s first articulated dump truck (top), nicknamed ‘Gravel Charlie’ and rated for just 10 tons of payload; and the A60H (bottom), the company’s newest model, claimed to be the largest articulated hauler with its 55-mt capacity.

Big Data Analysis to Improve with IoT ‘Edge’ Initiative

Cisco and IBM are pursuing a global collaboration to provide instant Internet of Things (IoT) insight at the “edge of the network,” enabling operations in remote and autonomous locations to tap into IBM’s Watson IoT and business analytics technologies and Cisco’s edge analytics capabilities to better understand and act on critical data.

In a press statement, the two technology companies noted that today billions of interconnected devices and sensors are gathering vast amounts of real-time data about the physical world. In recent years, cloud computing has offered companies a powerful way of storing that data and turning it into valuable insight. But for businesses without easy access to high bandwidth connectivity, these capabilities are sometimes out of reach or take too long. To address the problem, IBM and Cisco have joined forces to offer an approach intended to produce immediate, actionable insight at the point of data collection. The new approach is designed to target companies operating on the edge of computer networks such as mines, where time is of the essence but bandwidth is often lacking.

By coming together, IBM and Cisco said they are taking powerful IoT technologies the last mile, extending Watson IoT from the cloud to the edge of computer networks in order to make strong analytics capabilities available virtually everywhere.

For example, workers in remote environments will now be able to better monitor the health and behavior of critical machinery and more accurately plan for needed maintenance and equipment upgrades. By tapping into the power of the IBM Watson IoT platform and Cisco edge analytics, these companies can adopt the latest approaches to condition-based maintenance through which equipment is monitored in real-time, potentially helping reduce maintenance costs by up to 50% and increase productivity by 25%.

In a recent blog post, Maciej Kranzt, vice president of Cisco’s Corporate Tech-

ology Group, explained how the concept of “fog” computing and analysis will be vital in handling the flood of data from IoT sources.

According to Kranz, “The world is awash in data, and 90% of it was created in the last two years. In fact, every day, we create 2.5 quintillion bytes of data and that number is growing exponentially. The explosive growth of the Internet of Things (IoT) promises to add to this data glut, with 40% of all data coming from sensors by 2020. Today, a jet engine may generate 1 terabyte of data in a single flight, and a major global retailer collects 2.5 petabytes of customer day each hour. Yet 99.5% of all this data is never used or analyzed.

“The Internet of Everything (IoE) has enabled a plethora of real-time, high-data-rate applications that require a new approach, which we call ‘fog.’ By extending cloud capabilities to the edge of the network, fog computing moves analytics to the source of the data, enabling real-time processing and instantaneous action. Rather than moving massive amounts of raw data, the fog system sorts and indexes the data locally, and sends just alerts and exceptions back to the cloud,” he explained.

“The move toward fog analytics is well under way. In a recent survey of IT and operational technology (OT) professionals, 37% of respondents said that within three years, ‘most’ IoT data will be processed locally, at the edge of the network.

“Fog analytics will require a flexible network architecture, where some elements, such as policy, reside in the cloud while real-time data processing functions move to the edge,” according to Kranz. “Less time-sensitive data can still go to the cloud for long-term storage and historical analysis. Other requirements include standardization of device and data interfaces, integration with the cloud, and a scalable policy infrastructure.”