The Daunia coal mine in northeastern Queensland, Australia, reported it recently surpassed what it had previously claimed as a world record for the largest electronic detonator blast ever, by firing 5,665 detonators in 2,683 blastholes using the AXXIS digital detonation system from BME.

Last year, Daunia reported an AXXIS-controlled blast that successfully initiated 4,303 detonators in a single blast to break 2.8 million m3 of overburden.

The $1.7 billion coking coal mine was opened in September 2013 by the BHP Billiton Mitsubishi Alliance and is designed to produce 4.5 million metric tons per year over an estimated mine life of 30 years. Situated in Australia’s largest coalfield—the Bowen Basin—the surface mine has taken advantage of the benefits of electronic detonation to conduct larger blasts that generate greater operational efficiencies by reducing the number of mine stoppages that must take place every time blasting is conducted.

The mine also chose this technology in response to its faulty ground conditions. If not well controlled, faults tend to slide over each other during a blast; when using non-electric detonators, there is a possibility of the product being snapped by this movement of ground before it can be detonated, resulting in a misfire.

“These misfires are eliminated with electronics, as the detonator operates as a stand-alone entity the instant you push the ‘fire’ button,” said Trevor Grant, managing director of the Australia-based blasting optimization company Advanced Initiating Systems (AIS).

The latest record blast was prepared and carried out by Daunia staff using a single initiation point and one master control box. The blasting team was initially trained and certified by AIS, who are supplied by explosives firm BME; both companies are subsidiaries of Omnia Holdings, which is listed on the Johannesburg Securities Exchange.

“The use of the AXXIS system and electronic detonators allowed the mine to better control and manage the shock waves and rock movement arising from the faulty ground conditions,” said Grant. “The size and success of the blast demonstrates both the ease of use and the confidence that the client has in the system. Very few, if any, other electronic detonator suppliers empower clients to conduct blasts of this magnitude and complexity on their own.”

BME said its AXXIS electronic delay detonators feature very high accuracy, as well as timing flexibility between detonations. The average depth of each hole in the blast was 19 m, and the explosive was initiated from both top and bottom.

“The improved control of the blast helps keep vibration levels down,” said BME Technical Director Tony Rorke. “This in turn improves safety in the open-cast mining environment, as high vibration levels can undermine the integrity of the pit wall.”

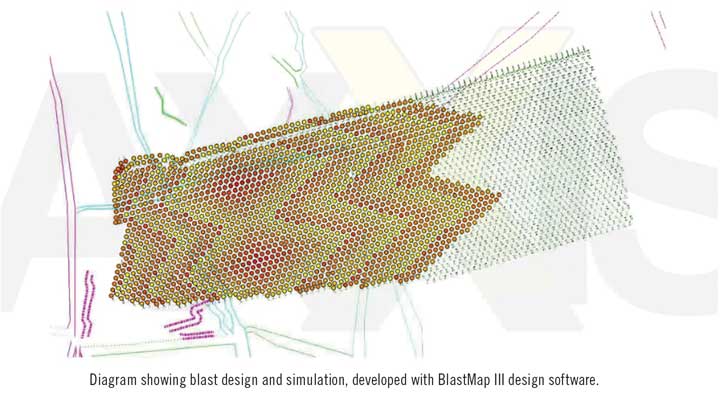

To design the blast, the Daunia team used BME’s BlastMap III blast design software, which was developed as an integral part of the AXXIS system.

The program allows complex timing designs and analysis of the results for each blast, and has just been released in an updated, second-generation version labeled BlastMap GII.

Mines Can Benefit From High-efficiency Motor Upgrades

By Chris Medinger

Mining and metals production are energy-intensive processes, with a significant proportion of energy consumption coming from purchased electricity. According to the Southwest Energy Efficiency Alliance—one of a number of regional energy efficiency organizations across the United States—a metal mining company’s energy expenditures can represent between 20% and 40% of its total production costs. However, today’s highly efficient motors, drives and mechanical power transmission products can significantly reduce the amount of energy consumed.

To encourage mining companies to retrofit standard motors to high-efficiency motors, a number of incentives and rebates are available from sources in the U.S. and elsewhere. For example, as far back as 2010, the U.S. Senate introduced legislation to create a rebate program to encourage the sale of high-efficiency industrial motors. The program was set up to provide a $25 per-horse power rebate for customers who purchased a high-efficiency motor for industrial and commercial use, including mining.

In Canada, Ontario’s mining industry spends more than $500 million annually on energy, which represents on average between 15% and 30% of operating costs, depending on the type of mining operation. To shorten payback periods, reduce capital costs, and cut operating expenses, Canada’s saveONenergy offers incentives for upgrading to premium efficiency motors.

In the European Union, electric motor-driven systems account for approximately 70% of total industrial electricity consumption and are responsible for approximately 60% in China. While replacing individual motors can save 3%–5%, optimizing entire motor systems could cut consumption by 20%–40%. Legislative efforts have been under way in several countries for more than a decade to encourage the transition to more efficient electric motor-driven systems.

The U.S. Department of Energy has explored and compared major industrial market verticals and energy use by major process systems. Its study noted that the mining industry ranked as the third-

highest energy user of motor-driven systems among 10 major industry verticals. Mining’s high position as an industrial energy consumer means that, under the right circumstances, mine operators could significantly benefit from investments aimed at upgrading existing motors, such as:

- Retrofitting or replacing underground support systems; e.g., ventilation fans and air systems.

- Upgrading motors or replacing conveyor systems.

- Efficiency improvements to crushing, separating or materials transportation processes.

- Retrofitting pumping systems in mine dewatering, slurry transportation and tailings disposal.

- Improvements in extraction and refining processes.

- Improvements in control systems or sensors.

- Installing variable speed drives for pumps, compressors and operating fans at partial load capacity.

Selecting the proper motor for an application—and providing adequate maintenance for it—are key elements in motor efficiency and performance. Consider the staggering costs of downtime: According to Caterpillar, it’s estimated that the total cost of unscheduled downtime can be as much as 15 times that of a scheduled event. Maintenance, because of its impact on return on capital, is a key driver of performance.

By reducing maintenance costs, companies can improve their performance. Preventative maintenance and regular analysis of motor load test performance are essential to achieve reliable performance. Selecting the right high-efficiency, heavy-duty motor for mining equipment is a critical step for OEMs and end-users. When a motor is put into an application that it is not designed for, it will cause many kinds of repetitive repair issues that even the best preventative maintenance practices will not correct.

When motor failures do occur, most can be attributed to bearing problems, and bearing failures usually stem from issues involving lubrication. Antifriction bearings should be re-lubricated on a regular basis. The lubrication schedule depends greatly on the motor’s operating environment and service conditions. While failures may occur due to lack of lubrication, bearings may also fail due to grease contaminated by water or other materials.

The second most common cause of motor failures is stator-winding failure. To ensure long motor life, it is important the motor operate within the temperature class of its insulation system and be kept clean and free of particle build up on the frame surface, air inlet and fans.

Mining companies are looking at cutting costs by, among other things, using more efficient equipment to ease energy demand and reduce downtime. Increasing investment in high-efficiency, heavy-duty motors would separate profitable, growth-oriented companies from the pack and equip them with a sustainable competitive advantage.

The payback times for motor investments can be within a couple of years and offers a positive impact on both the environment and the operation. The mining community is being challenged to find electrical equipment and systems solutions that make mining operations reliable, efficient, and continuous; safer and protected; and sustainable high-efficiency, heavy-duty motors are one way to achieve these goals.

Chris Medinger is product marketing specialist with Leeson Electric and may be reached at (262) 387-5410 or chris.medinger@leeson.com. Leeson is a Regal brand located in Grafton, Wisconsin, USA. Regal Beloit Corp. is a leading manufacturer of electric motors, mechanical and electrical motion controls, and power generation products.

A view of the blast area at the Daunia mine prior to detonation. The blast involved 5,665 detonators in 2,683 blastholes.

Diagram showing blast design and simulation, developed with BlastMap III design software.