Trimble and Peck Tech Consulting, Montreal, Quebec, announced in mid-February that Trimble will distribute Peck Tech’s uGPS Rapid Mapper system, a new laser-based mobile mapping and surveying system used in underground mines. It can be deployed as a stand-alone underground mapping system or can be integrated with Trimble’s underground Mine Information System.

|

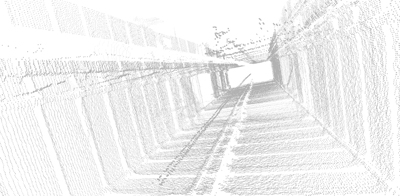

| Examples of underground working spaces delineated by uGPS Rapid Mapper. |

Applications for uGPS Rapid Mapper include development pickups, volumetric analyses and shaft scanning in underground mines. UGPS Rapid Mapper uses sophisticated mapping and filtering algorithms to provide accurate, georeferenced 3-D point cloud data faster than conventional mapping methods.

UGPS Rapid Mapper can be installed on any underground vehicle to generate point cloud data at normal operating speeds. Data is accessible via downloadable Wi-Fi, Ethernet or USB memory devices, and is easily imported to a wide variety of third-party software. UGPS Rapid Mapper is brand neutral to mining equipment and software for mounting on any underground mobile equipment. It can also be integrated with Trimble or third-party software applications and information systems.

|

| Examples of underground working spaces delineated by uGPS Rapid Mapper. |

The uGPS Rapid Mapper adds underground mobile mapping capabilities to Trimble’s solutions portfolio and extends its Connected Mine approach for mining, designed to provide a dependable source of information for decision support across global surface and underground operations.

“Mines are increasingly looking for new technology that offers accurate and highly efficient solutions that help them react faster to their dynamic physical as well as economic environments,” said Nathan Pugh, business area director of Trimble’s Mining Division. “UGPS Rapid Mapper extends our mapping and surveying solutions to underground mining where customers will be able to quickly harvest, process and use this data for better overall decision making.”

Trimble and Neptec Technologies Corp., Ontario, Canada, agreed last September to a distribution and technology development arrangement that allows Trimble to distribute Neptec’s obscurant-penetrating laser scanners (OPAL) and 3-D real-time intelligence (3DRi) software. In addition, Trimble plans to integrate data from Neptec’s scanners and software with Trimble’s geospatial and enterprise-level mine information solutions for the mining industry.

Neptec, which develops 3-D machine vision products for machine automation and robotics applications in harsh environments, recently announced successful proof-of-concept testing of its 3DRi Spot Assist application at Teck’s Fording River coal mine in British Columbia, Canada. Developed in collaboration with Barrick, Teck Resources, and Peck Tech Consulting, 3DRi Spot Assist is a sensor-based software application that uses Neptec’s 3DRi (3-D real-time intelligence) software development platform and obscurant-penetrating OPAL 3-D laser sensors to improve the productivity and safety of operations in the loading area of open-pit mines.

“Backing up a haul truck beside a shovel for loading is a challenging task at the best of times and a system that improves the efficiency and safety of shovel and haul truck interactions offers potentially huge productivity gains for mining operations,” said Peter Wan, Teck’s principal advisor on mining technology.

3DRi Spot Assist uses multiple OPAL 3-D sensors mounted on the shovel together with a single computer running the 3DRi SDK and Spot Assist software application to continuously scan the loading area around the shovel and recognize and track haul trucks as they prepare to spot beside the shovel for loading. The application calculates the optimal loading position beside the shovel, determines a valid path for the haul truck to back up into that position, and provides the haul truck driver with cues on a display in the truck during the spotting maneuver. The system supports single and double-sided loading configurations. It also alerts the shovel and haul truck operators to obstacles that may appear in the path, and reports on spotting efficiency to assist with operator training and benchmarking.

“Decreased productivity and increasing high costs in the mining industry require us to innovate, it is no longer an option,” said Andrew Scott, Barrick’s senior director of mining information technology and automation. “While full automation is the long-term goal, we can see many possible applications of Neptec’s 3DRi and OPAL technologies to create intelligent, real-time 3-D solutions that help our operators perform complex tasks more efficiently and with less risk.”